Heat supplying device

A heating device, gas inlet technology, applied in water heaters, fluid heaters, regulating fuel supply, etc., can solve the problems of heat waste, insufficient heat, etc., and achieve the effect of high degree of automation and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

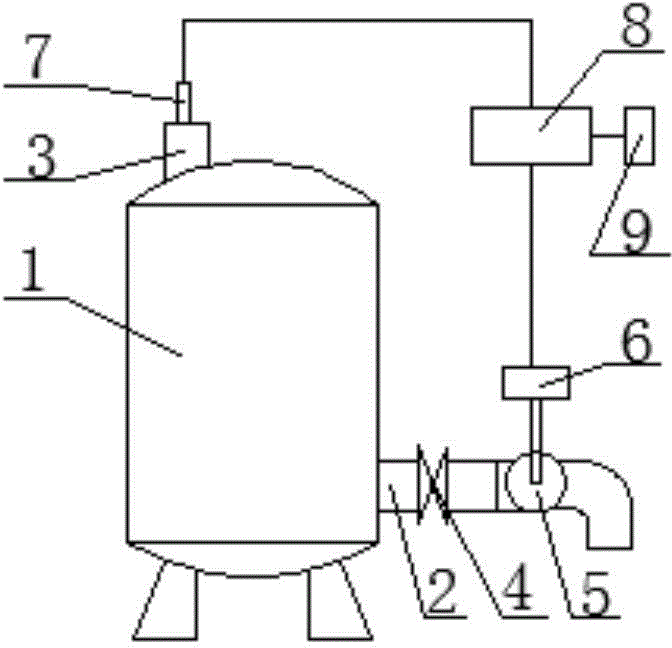

[0012] Such as figure 1 As shown, a heating device includes a boiler 1, a gas inlet 2 and an outlet 3 are provided on the boiler 1, a valve 4 is provided at the gas inlet 2, and a gas inlet 2 is connected to a fan 5 through a pipeline, and the fan 5 is provided by Driven by a variable frequency motor 6, a tester 7 is arranged at the exit 3, the tester 7 is connected to a controller 8, the controller 8 is connected to the variable frequency motor 6, and the controller 8 is also connected to a display 9.

[0013] The working process of this example: open the valve 4, the frequency conversion motor 6 drives the fan 5 to blow natural gas into the boiler 1, after the natural gas is burned in the boiler, the detector 7 at the outlet 3 detects the combustion of the natural gas in the boiler 1, and collects The received data is transmitted to the controller 8, and the controller 8 transmits the data to the display 9, and at the same time analyzes the heating condition in the boiler 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com