Five-layer corrugated cardboard production line realizes the production method of changing rolls without stopping

A corrugated cardboard and production method technology, applied in the direction of mechanical processing/deformation, etc., can solve the problems of occupying production time, frequent roll change, large output impact, etc., and achieve the effect of saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

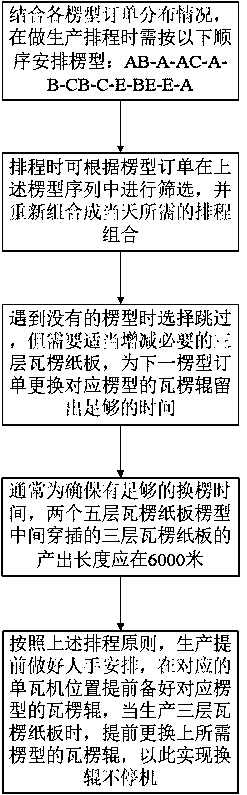

Method used

Image

Examples

Embodiment

[0024] 1. Production of AB flute, and subsequent production of AC flute. The 4 steps can be changed to AC flute without stopping the machine. The steps are as follows:

[0025] Step 1: When producing AB flute, A and B tile rollers are produced on the machine, and C tile rollers are prepared at the position of the B car single tile machine;

[0026] Step 2: When A flute is produced, the B flute roller is stopped, and the disassembly is started to replace the C tile roller;

[0027] Step 3: After the tile roller B is off the machine, replace the tile roller C immediately, connect the steam pipe, complete the work of threading and connecting paper, and prepare for production;

[0028] Step 4: After the production of A flute is scheduled, the C roll is started to produce AC flute, no special shutdown is required to change the roll, and the B roll is ready for subsequent production.

[0029] 2. In the production of AB flute, CB flute will be produced in the future. The 4 steps can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com