Full-automatic ceramic wafer weighing and sorting production line and weighing and sorting method

A fully automatic, ceramic chip technology, used in cleaning methods, sorting, chemical instruments and methods using gas flow, etc., can solve the problems of ceramic chip product damage, affecting efficiency, and slow sorting methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

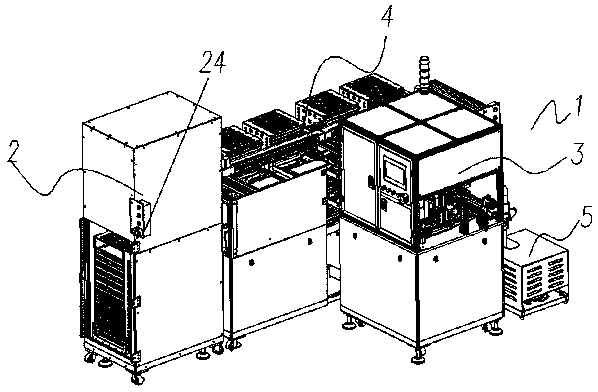

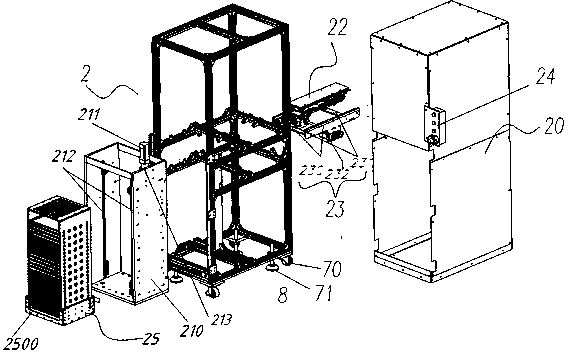

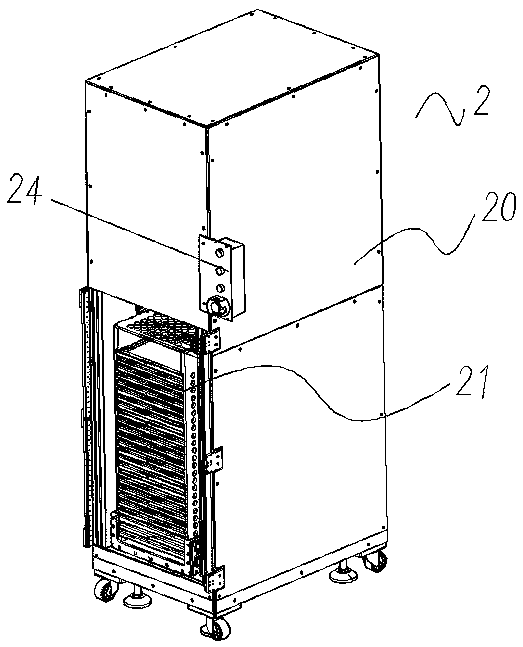

[0046] Examples, see attached Figure 1~Figure 22 A full-automatic weighing and sorting production line 1 for ceramic sheets includes an automatic tray feeding device 2, a material weighing and sorting device 3, and a sorting and unloading device 4, and the automatic tray feeding device 2 is arranged on the sorting and unloading device 4 On one side, the material weighing and sorting device 3 is arranged on the front of the sorting and unloading device 4, and one side of the material weighing and sorting device 3 is provided with an air compressor 5, and the air compressor 5 is used to communicate with The automatic disk feeding device 2, the material weighing and sorting device 3, and the connection of the pneumatic devices on the sorting and unloading device 4 provide driving energy for them to realize clamping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com