Array substrate mother board, manufacturing method of array substrate mother board, display device and manufacturing method of display device

The technology of an array substrate and its manufacturing method, which is applied in the display field, can solve problems such as the inability to load the driving signal of the driving circuit, and achieve the effect of saving mold opening costs and realizing narrow borders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This embodiment provides a method for manufacturing an array substrate motherboard, including:

[0049] providing a base substrate;

[0050] forming a plurality of via holes through the base substrate;

[0051] forming a conductive post in the via hole;

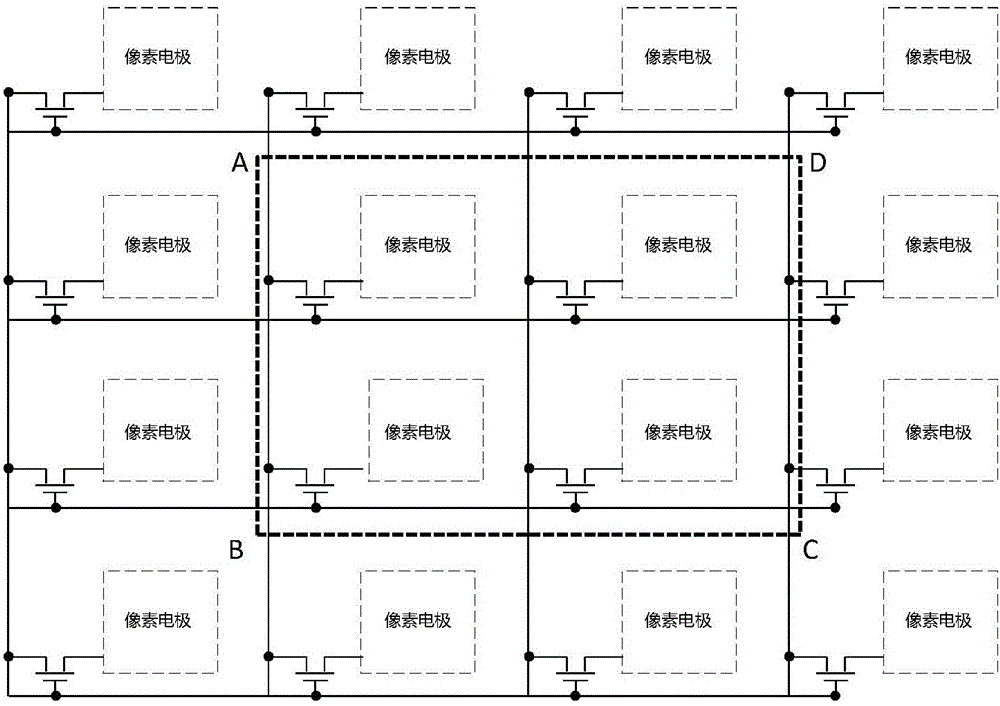

[0052] A plurality of display units arranged in an array are formed on the first surface of the base substrate, each display unit includes a thin film transistor and a pixel electrode, and the gate electrode and source electrode of each thin film transistor are respectively electrically connected to a conductive column.

[0053] In this embodiment, a plurality of via holes penetrating the base substrate are formed on the base substrate, conductive pillars are formed in the via holes, a display unit is formed on one surface of the base substrate, and the gate electrode and the gate electrode of the thin film transistor in the display unit are The source electrodes are respectively electrically connected to a conductiv...

Embodiment 2

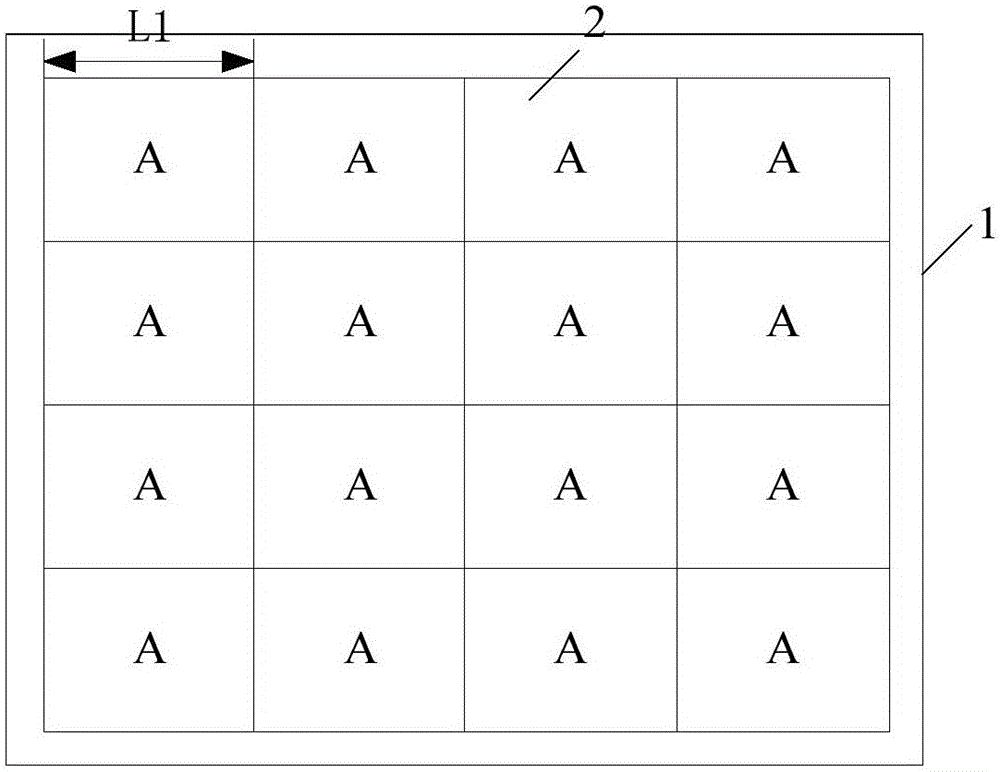

[0060] This embodiment provides an array substrate mother board, which is manufactured by using the manufacturing method described in Embodiment 1. The array substrate includes a base substrate, and the base substrate includes a plurality of processes passing through the base substrate. A conductive column is formed in the via hole, and a plurality of display units arranged in an array are formed on the first surface of the base substrate, each display unit includes a thin film transistor and a pixel electrode, and the gate of each thin film transistor The electrode and the source electrode are respectively electrically connected to a conductive column.

[0061] In this embodiment, the base substrate includes a plurality of via holes penetrating the base substrate. Conductive pillars are formed in the via holes. A display unit is arranged on one surface of the base substrate. The gate electrode and source of the thin film transistor in the display unit The electrodes are respe...

Embodiment 3

[0068] This embodiment provides a method for manufacturing a display device, including:

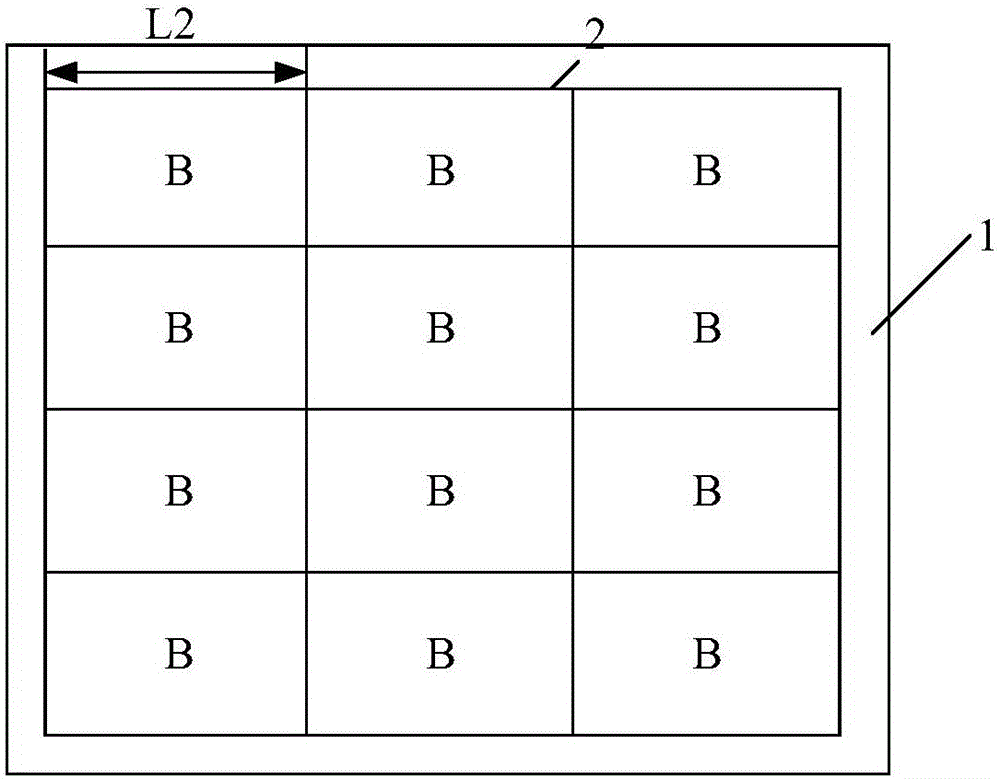

[0069] cutting the above-mentioned array substrate mother board to obtain an array substrate with a preset size;

[0070] A driving circuit is adhered on the second surface of the array substrate opposite to the first surface, and a conductive lead connecting the conductive column and the driving circuit is formed.

[0071] In this embodiment, the array substrate motherboard can be freely cut. After the array substrate motherboard is cut into any shape and size, the drive circuit can be attached to the other surface of the substrate substrate, and the conductive lead and conductive The pillar realizes the connection between the driving circuit and the electrode of the thin film transistor, so that the driving signal is loaded into the display unit, and the display unit is driven to display. Through the technical solution of the present invention, it is possible to cut the motherboard of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com