Brake force monitor for elevator brakes

A technology of brakes and monitors, applied in the field of elevators, can solve the problems of readings deviating from the original calibration state, expensive, sensor drift, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

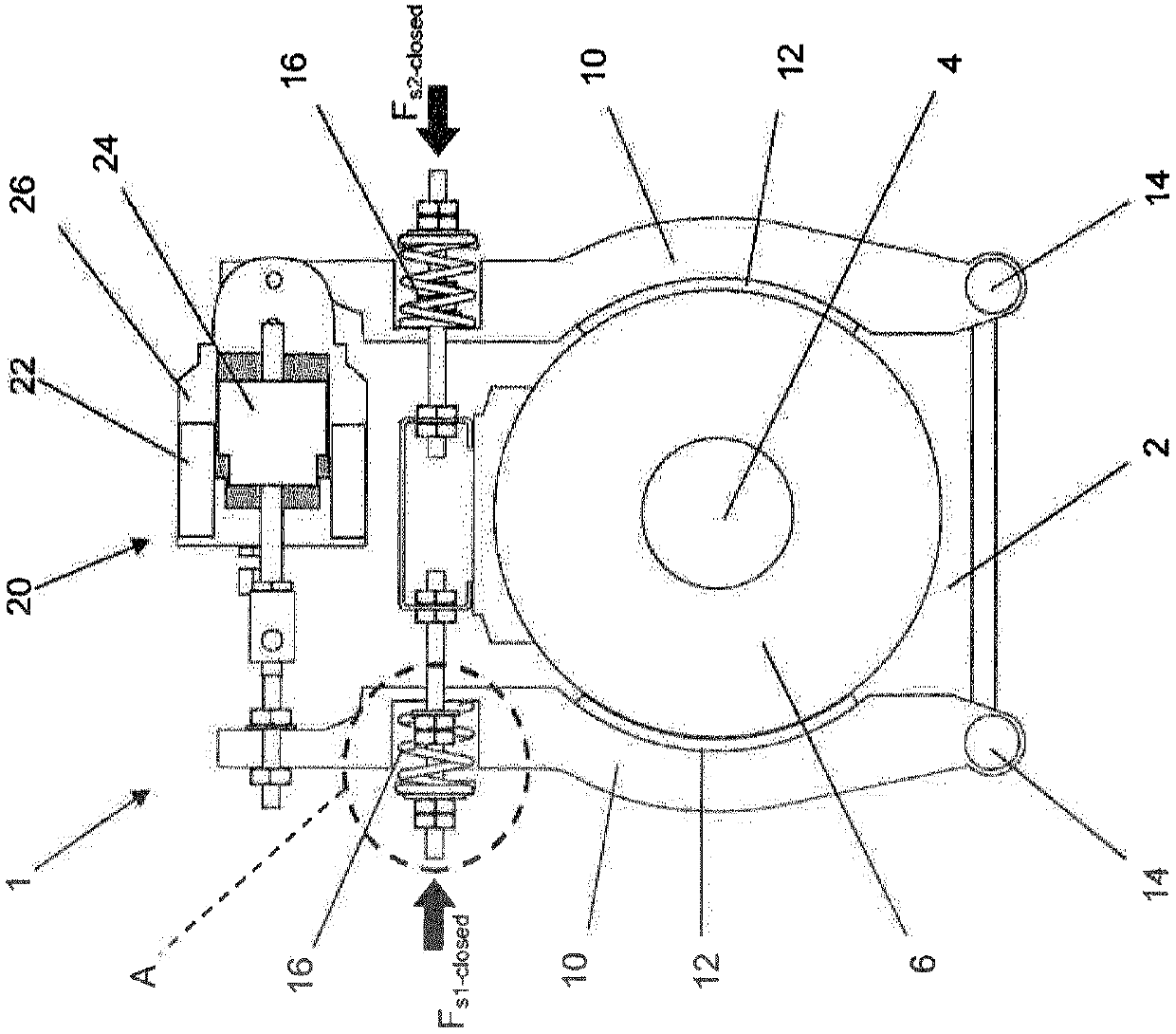

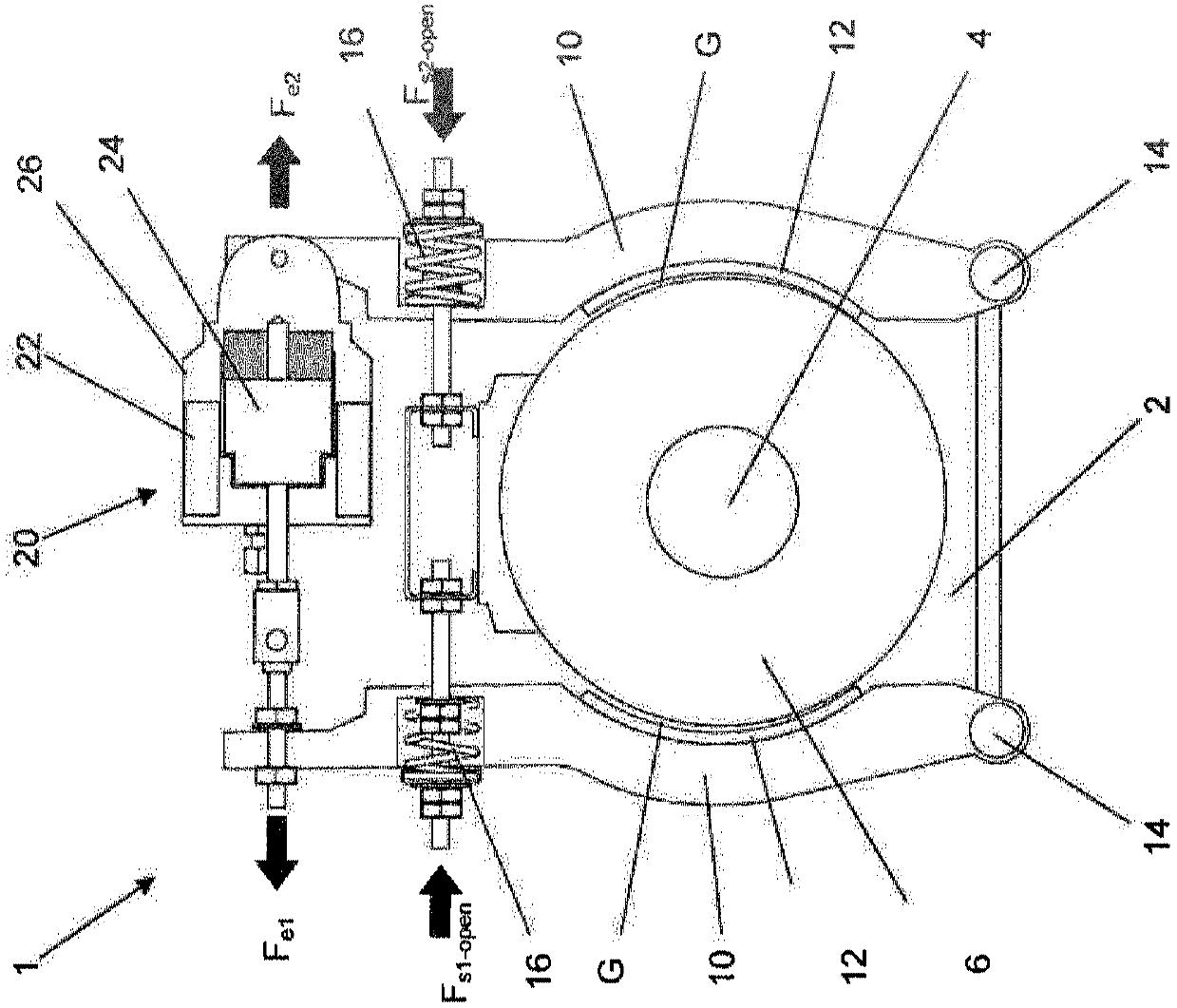

[0035] figure 1 and figure 2 is a schematic plan view of the same elevator brake 1 . figure 1 depicts brake 1 in its closed position, while figure 2 The brake 1 is shown in its open position. The brake 1 comprises a brake drum 6 mounted directly to a shaft 4 connected directly to the motor, or alternatively indirectly via gears. Two brake arms 10 are arranged at opposite sides of the drum 6 and are mounted at their lower ends to pivots 14 connected to the housing 2 of the motor or gear. Each arm 10 is fitted with a brake pad 12 and is biased towards the drum 6 by a pre-tensioned compression spring 16 . The force exerted by the spring 16 on the brake arm 10 is represented by the arrow F s1 and F s2 show. The electromagnetic actuator 20 is disposed between and interconnects the upper ends of the brake arms 10 . The actuator 20 includes a housing 26 containing a series of solenoid coils 22 and a movable solenoid plunger 24 extending from the housing 26 .

[0036] in such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com