An automobile front windshield material rack

A front windshield and material rack technology, applied in the field of support frames, can solve the problems of simple frame structure, windshield damage, windshield friction and collision, etc., and achieve the effect of reducing friction, reasonable structure setting, and convenient placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

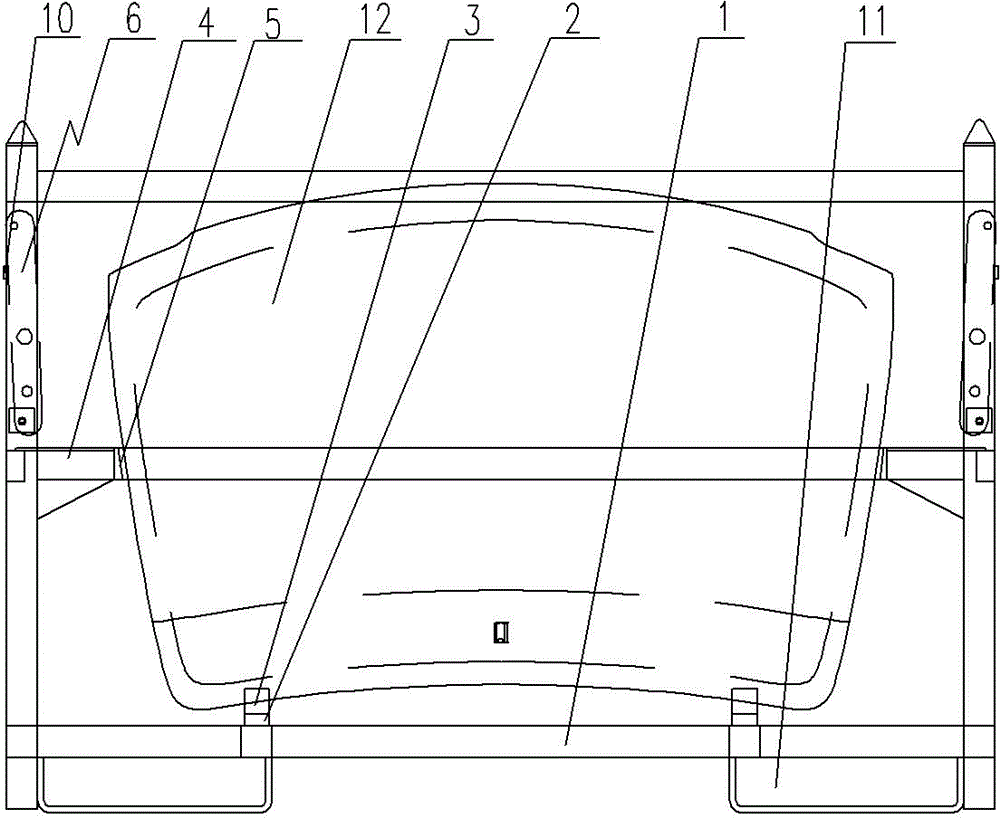

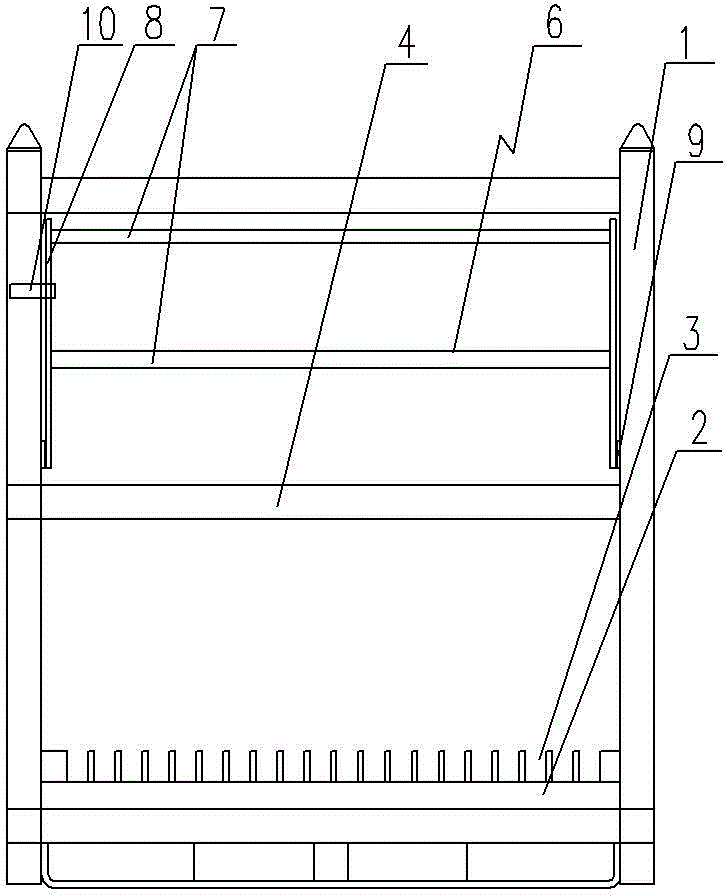

[0010] See figure 1 , figure 2 As shown, a car front windshield material frame, which includes a bracket 1, two symmetrical longitudinal support bars 2 are arranged at the bottom of the bracket 1, and the bottom card slots 3 are evenly opened on the longitudinal support bars 2, and the two sides of the bracket 1 are respectively Symmetrical side support frame 4, the side support frame 4 is uniformly provided with side draw-in slots 5 matching with the bottom draw-in slots 3, rubber strips are installed on the side draw-in slots 5, the two sides of the bracket 1 on the top of the side support frame 4 The rotatable compression frame 6 is respectively installed, and the compression frame 6 includes two compression rods 7 arranged in parallel, and the two compression rods 7 are connected by a side connecting plate 8, and the ends of the side connecting plate 8 pass through a rotating shaft 9 Connect the bracket 1; a limit plate 10 is installed on the bracket 1, and the compressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com