A pipe path installing rack assembly

A technology for installing racks and pipelines, which is applied in the directions of pipeline supports, lifting devices, pipes/pipe joints/pipe fittings, etc. It can solve the problems of messy appearance, poor vision of the gantry, and large space occupation, and achieve the effect of compact and reasonable layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

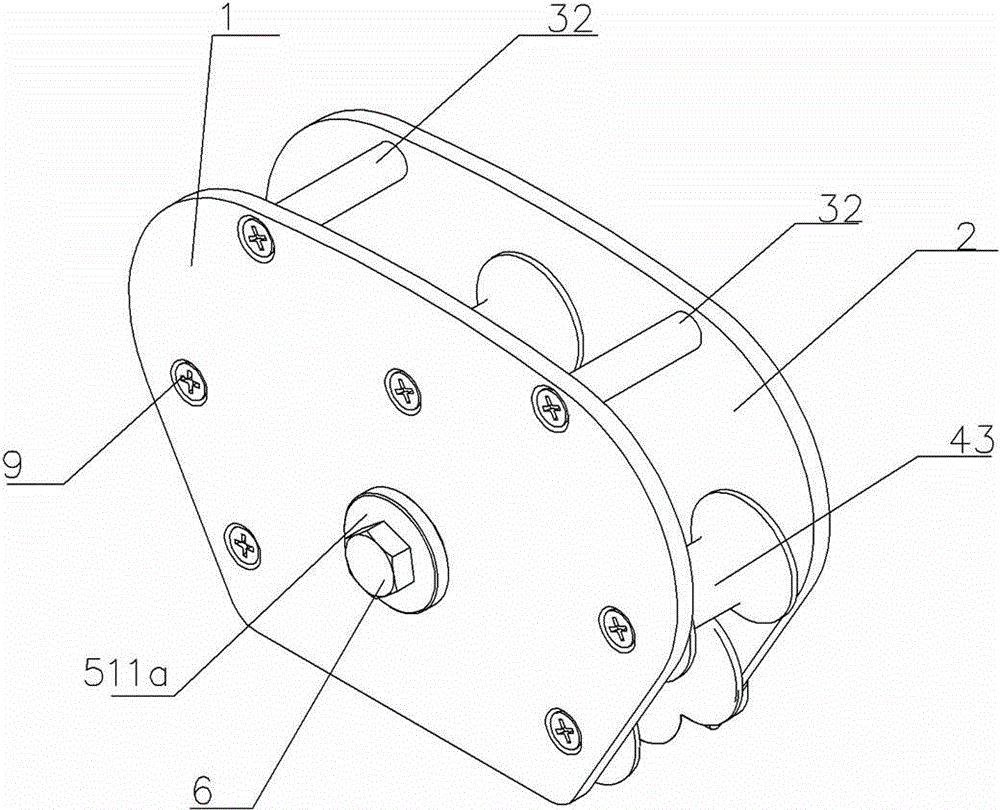

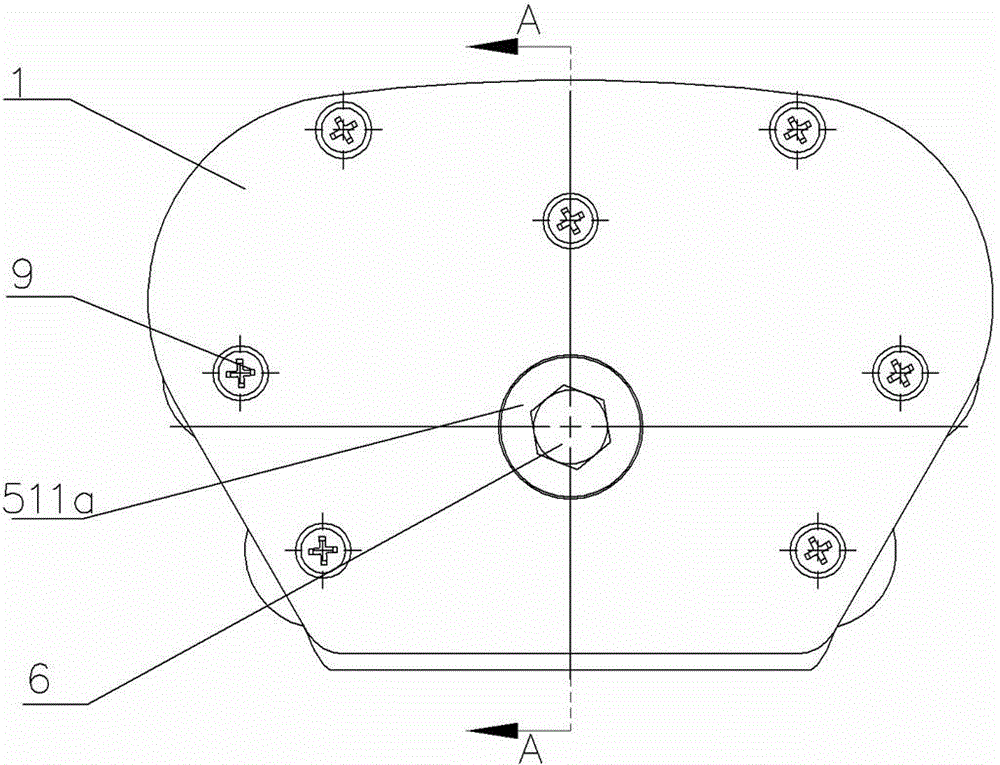

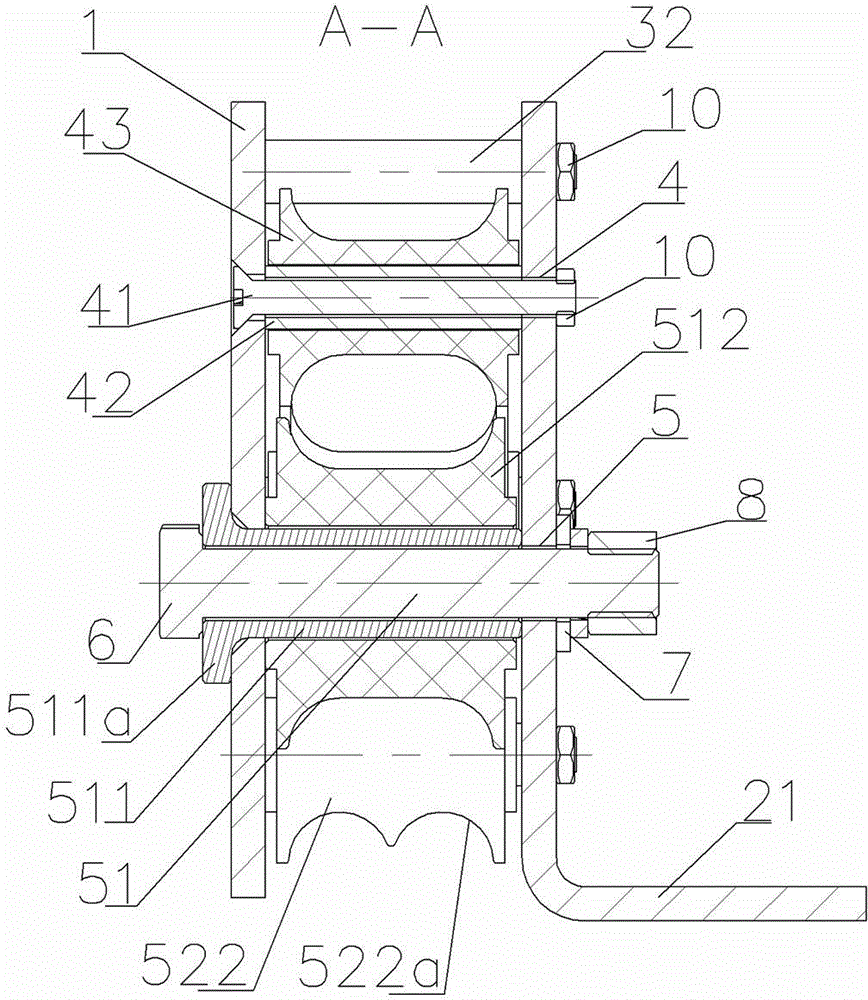

[0023] See Figure 1 to Figure 5 , the present invention includes a symmetrically arranged front mounting plate 1 and a rear mounting plate 2, a distance is left between the front mounting plate 1 and the rear mounting plate 2, and a pipe wheel structure is connected between the front mounting plate 1 and the rear mounting plate 2 ; The front mounting plate 1 and the rear mounting plate 2 are fan-shaped plates with arc sides, which can save the space of the overall structure; It coincides with the center connection line of the corresponding through holes on the rear mounting plate 2; the through holes are distributed in three rows of upper row, middle row, and lower row from top to bottom on the front mounting plate 1 and rear mounting plate 2; The number of through holes 3 in the upper row is two, and the two through holes 3 are symmetrically arranged on the center line of the front mounting plate 1 and the rear mounting plate 2 in the vertical direction; the number of throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com