Calibration method of probe tube of inclinometer of mining rotary drill

A calibration method and technology of rotary drilling rig, applied in the field of data fusion, can solve the problems of unfavorable small and micro enterprise production, high price of three-axis Helmholtz coil and three-axis non-magnetic turntable, and low calibration accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

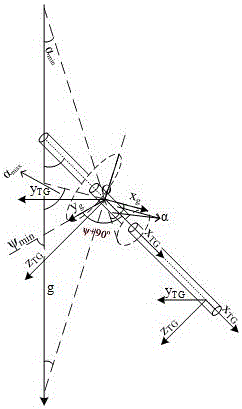

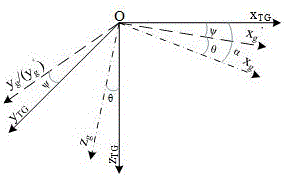

[0026] On the basis of the above-mentioned specific implementation, further implement the calibration method of the probe tube of a kind of mining rotary drilling rig inclinometer, the calibration method is to first provide the error model of the three-axis sensor, and then give the error model according to the error model Implementation steps of the calibration method.

[0027] 1) Three-axis gravity acceleration sensor

[0028] Because there is no cross-axis interference in the three-axis gravity acceleration sensor, its error matrix is an upper triangular matrix.

[0029]

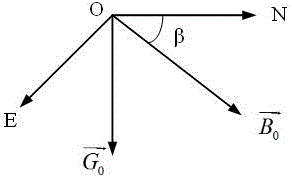

[0030] where g TG is the three-axis component of the gravity vector in the probe (vehicle) coordinate system, g is the measured value of the three-axis gravity acceleration sensor in the earth's gravity environment, K g is the error matrix of the gravity acceleration sensor, b g is the zero drift error of the three-axis sensor, C gTG is the rotation matrix from the three-axis gravity acceleration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com