a clamping device

A splint and clamping technology, applied in primary batteries, primary battery manufacturing equipment, sustainable manufacturing/processing, etc., can solve the problems of high battery failure rate, easy extrusion of polymers, electrolyte contamination on the back of pole pieces, etc. To achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

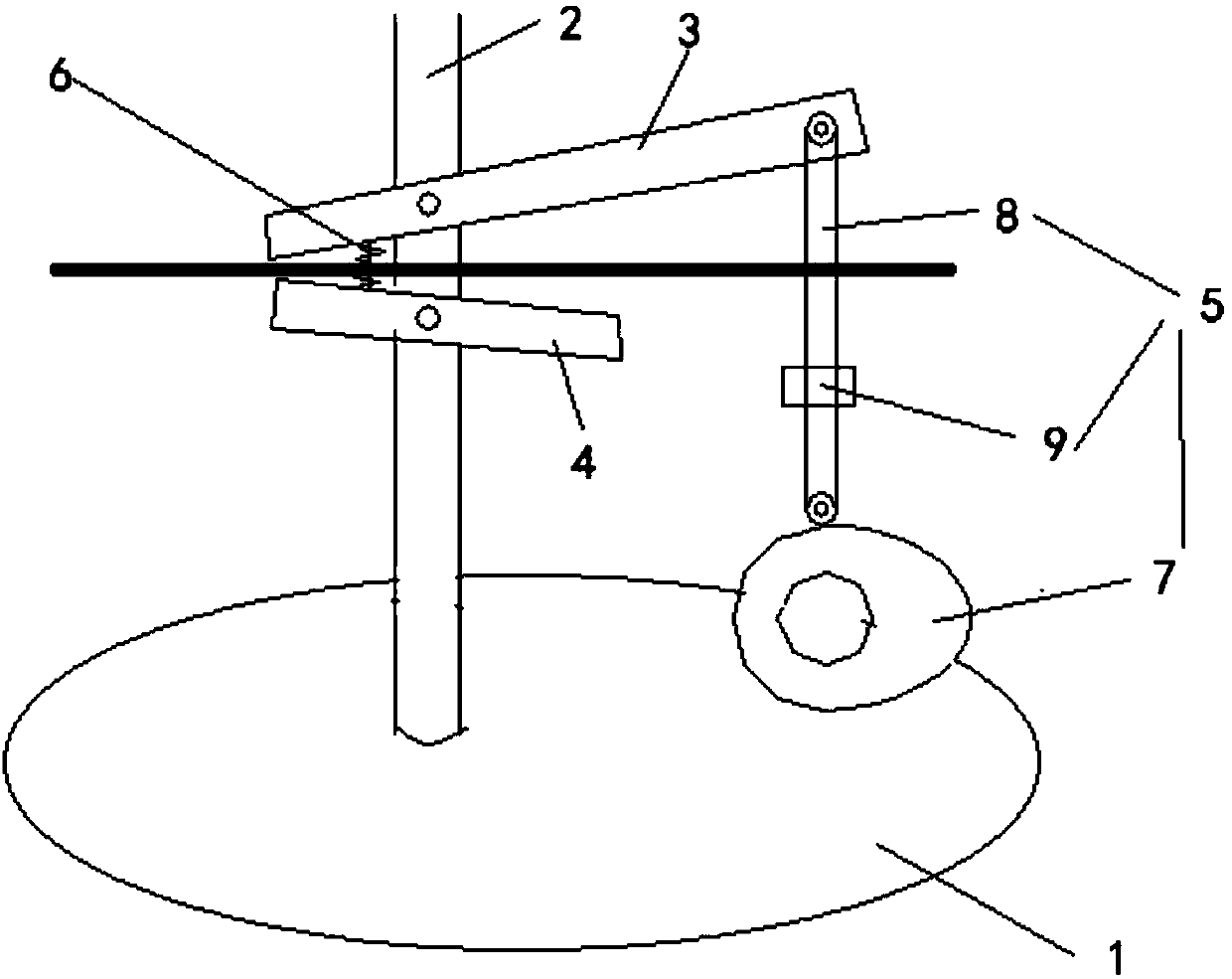

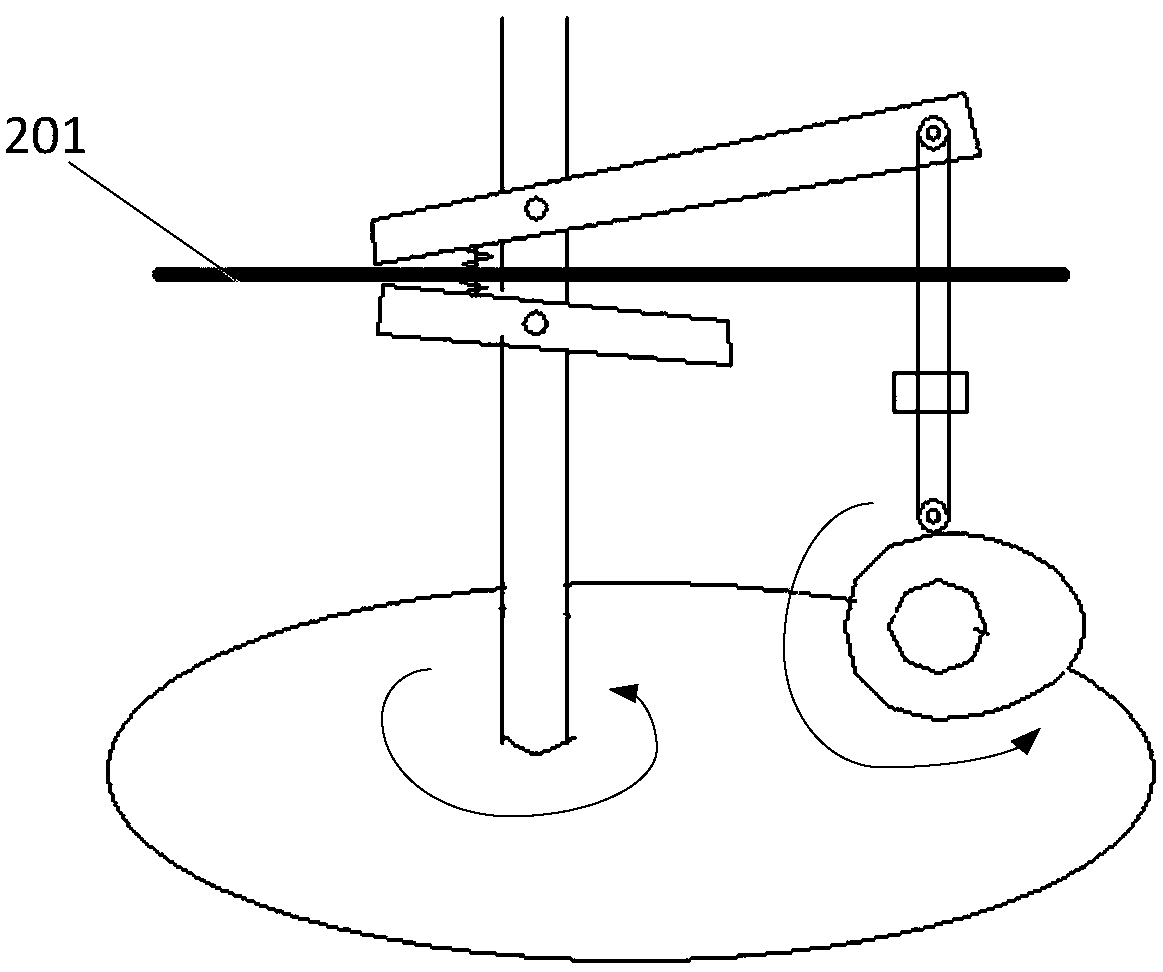

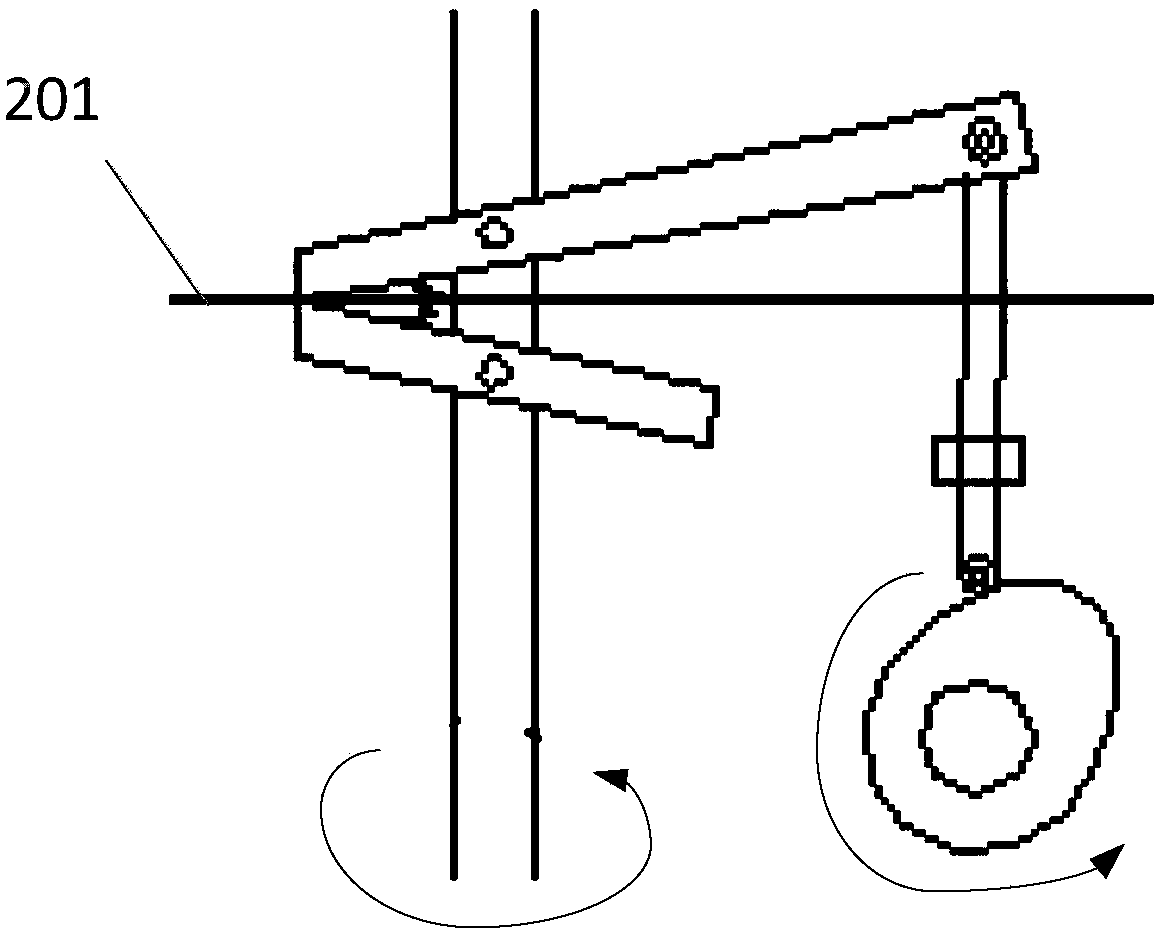

[0024] The embodiments of the present application provide a pinch device, which solves the technical problems of the pole piece transport device in the prior art that the back of the pole piece is easily contaminated with electrolyte and the polymer is easily extruded, resulting in high failure rate of the battery. Provided is a pole piece clamping device capable of improving the reliability of produced batteries.

[0025] In order to solve the above technical problems, the general idea of the technical solution provided by the embodiment of the present application is as follows:

[0026] The application provides a clamping device, comprising:

[0027] a first rotating member;

[0028] a fixed pin rod, the fixed pin rod is fixed on the first rotating part so as to be able to rotate with the first rotating part;

[0029] Clamping mechanism, the clamping mechanism includes an upper splint, a lower splint and a power part; the upper splint and the lower splint are fixed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com