Eleven-roller straightener roller system zero calibration method

A technology for straightening rolls and zero calibration, applied in the field of metallurgy, can solve the problems of long time for zero calibration of the roll system of the straightening machine, can not meet production requirements, affect the inaccuracy of zero calibration, etc., so as to save time and manpower, and improve the service life. and effect, the effect of convenient zero calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

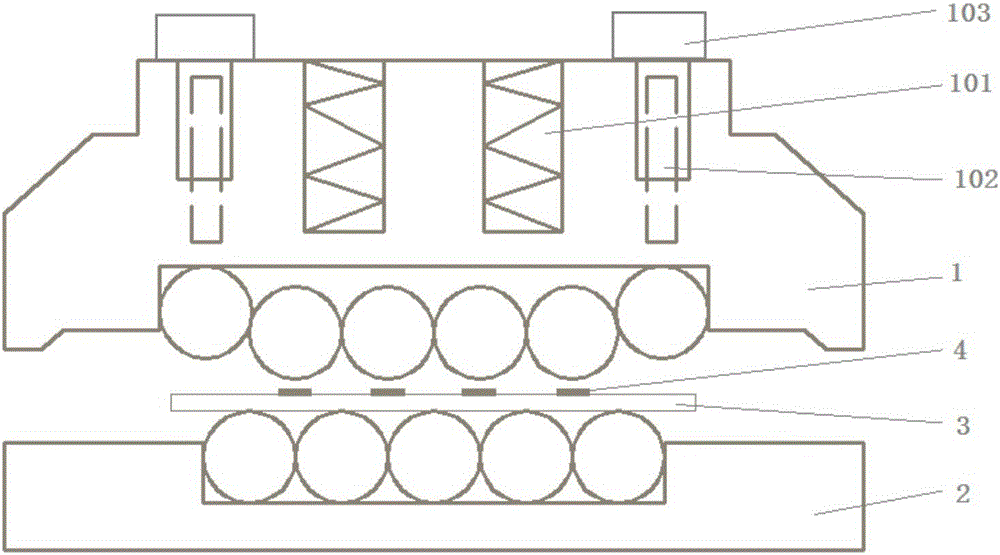

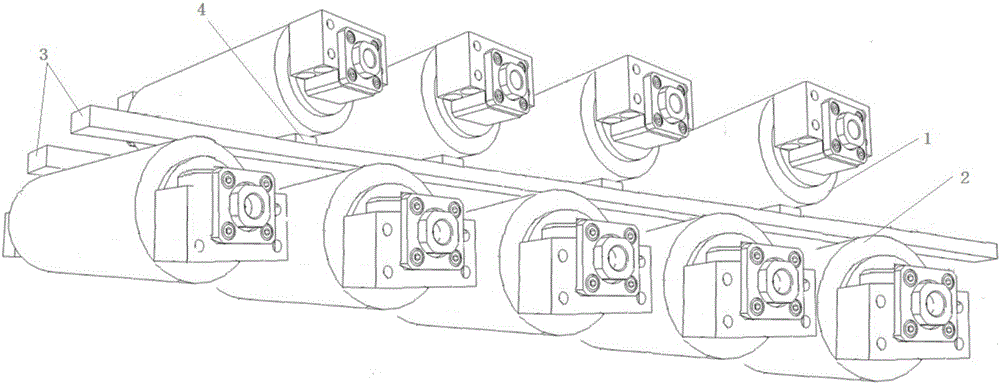

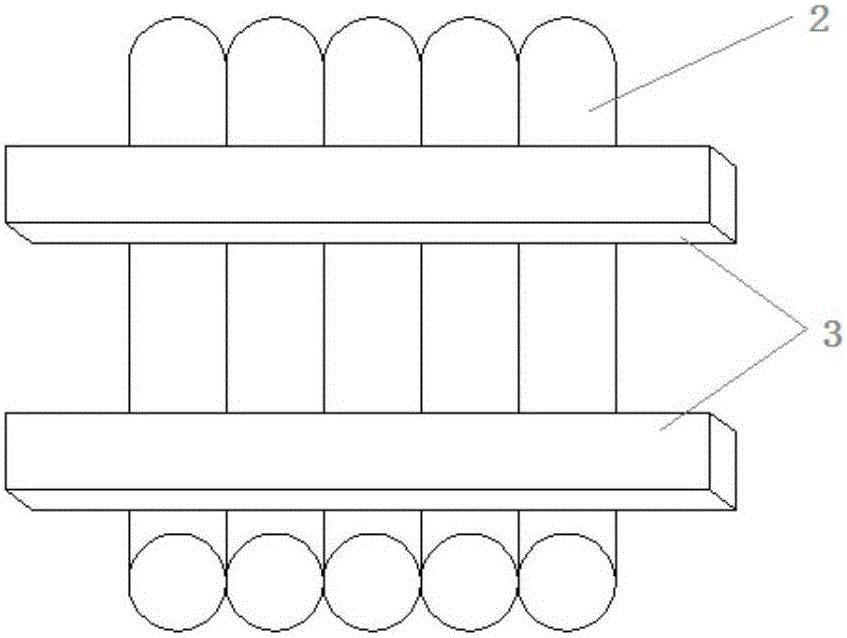

[0044] like figure 1 Shown: the 11-roller straightening machine includes a balance cylinder 101, a screw down screw 102, a down motor 103, a hydraulic pad system (not shown) and a main balance system (not shown), and its roll system includes an upper roll system 1 and the lower roller system 2, the middle part of the upper roller system 1 is connected with two said balance cylinders 101 arranged symmetrically along its center, and one said pressing screw rod 102 is respectively connected to each of its four azimuth angles, The four depressing screw rods 102 are respectively connected to a depressing motor 103 through a coupling (not shown), the hydraulic cushion system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com