Hinge damping buffer structure

A cushioning structure and hinge technology, which is applied to hinges with pins, building structures, door/window accessories, etc., can solve problems such as not having a good cushioning effect, failing to meet the use requirements, and affecting the life of the buffer, and achieving overall The appearance is simple, the service life is improved, and the cushioning effect is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

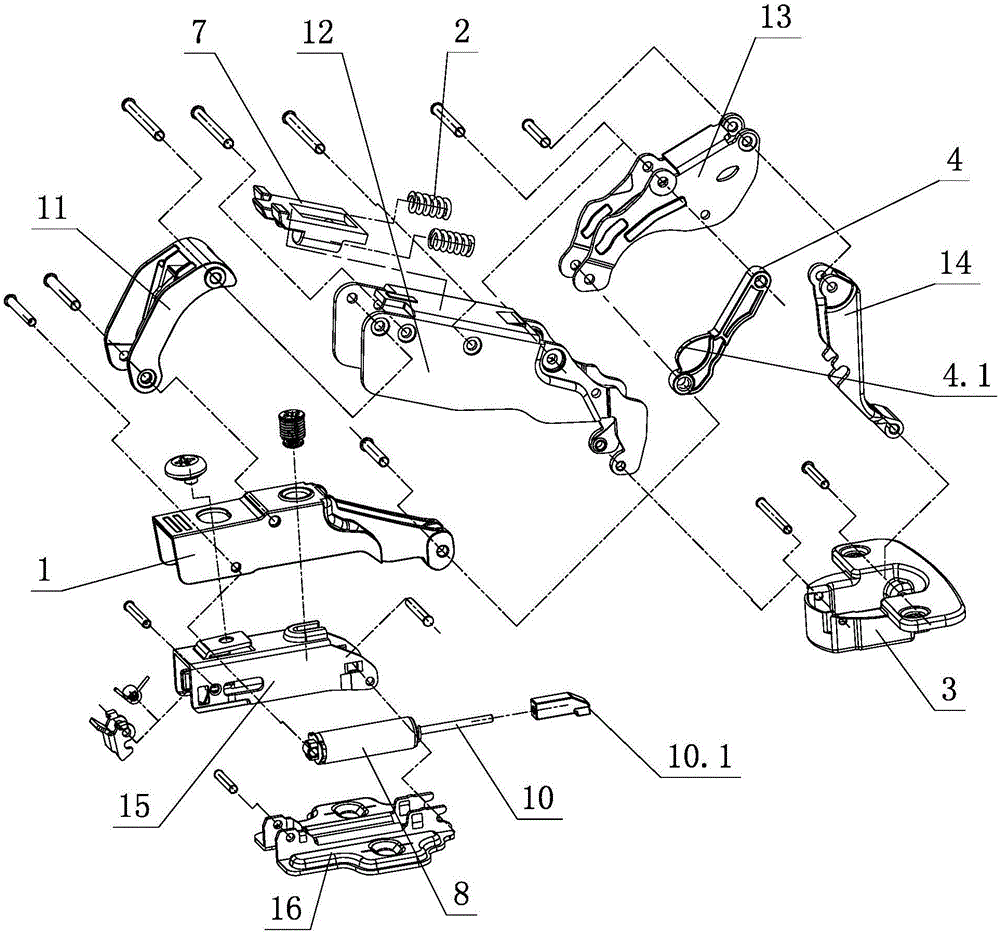

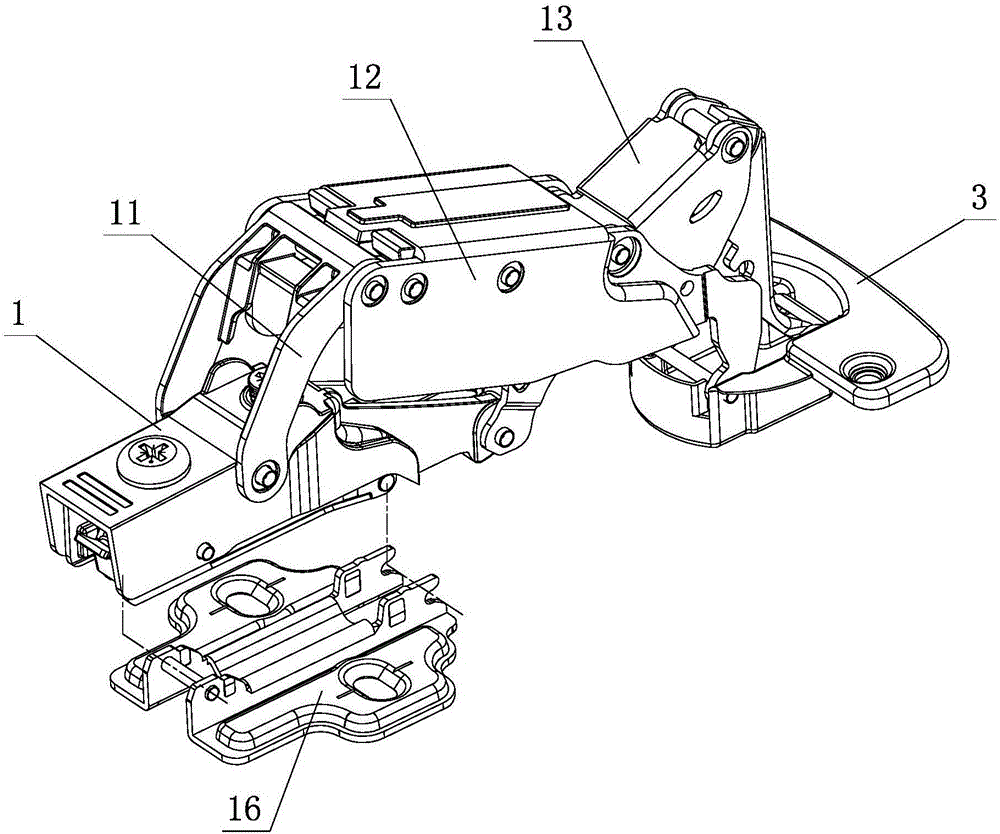

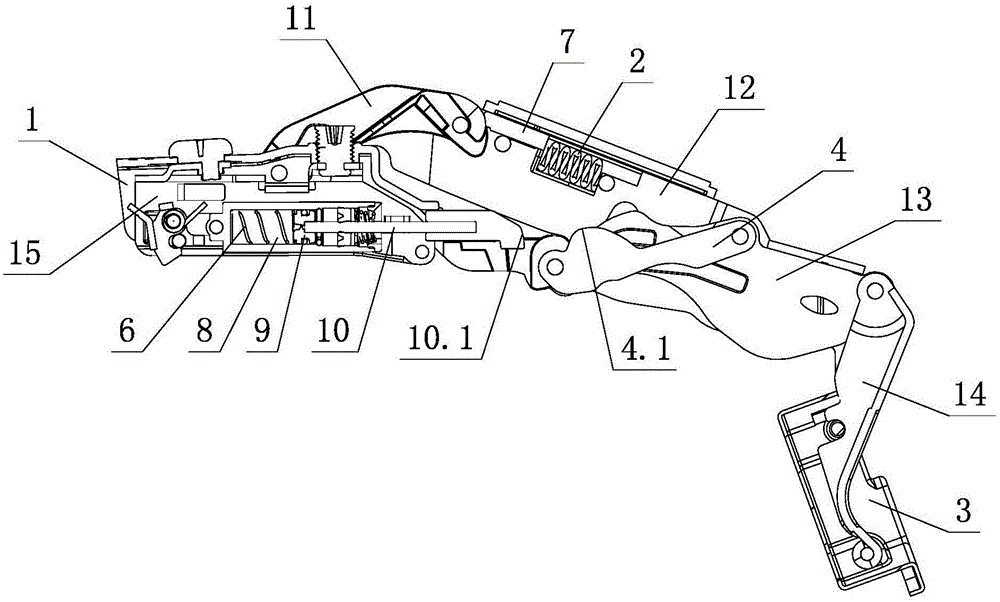

[0021] see Figure 1-Figure 7 , the hinge damping buffer structure includes a connecting arm 1, a hinge cup seat 3, a transmission arm assembly and an elastic assembly, the two ends of the transmission arm assembly are rotatably connected to the connection arm 1 and the hinge cup seat 3 respectively, and the elastic assembly is arranged on the transmission arm assembly , the connecting arm 1 is hinged with the hinge cup seat 3 through the cooperation of the transmission arm assembly and the elastic assembly, so as to realize the hinged opening and closing of the hinge. The element 4 is provided with a meandering area 4.1. The meandering area 4.1 acts on one end of the damper at least when the hinge is closed for a stroke. The damper slides on the connecting arm 1 and compresses to generate a damping buffer force. The meandering area 4.1 acts at least wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com