Vehicle power transmission device

A technology for power transmission devices and vehicles, applied in the direction of transmission devices, belts/chains/gears, mechanical equipment, etc., can solve problems such as vibration and unbalanced load offset, and achieve the effect of reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

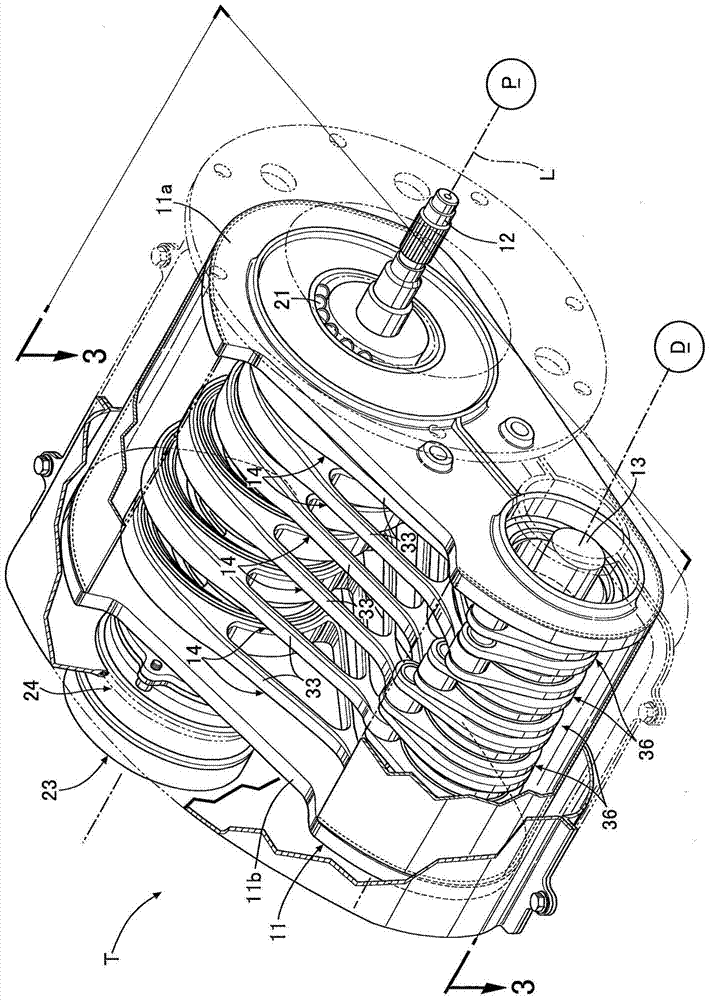

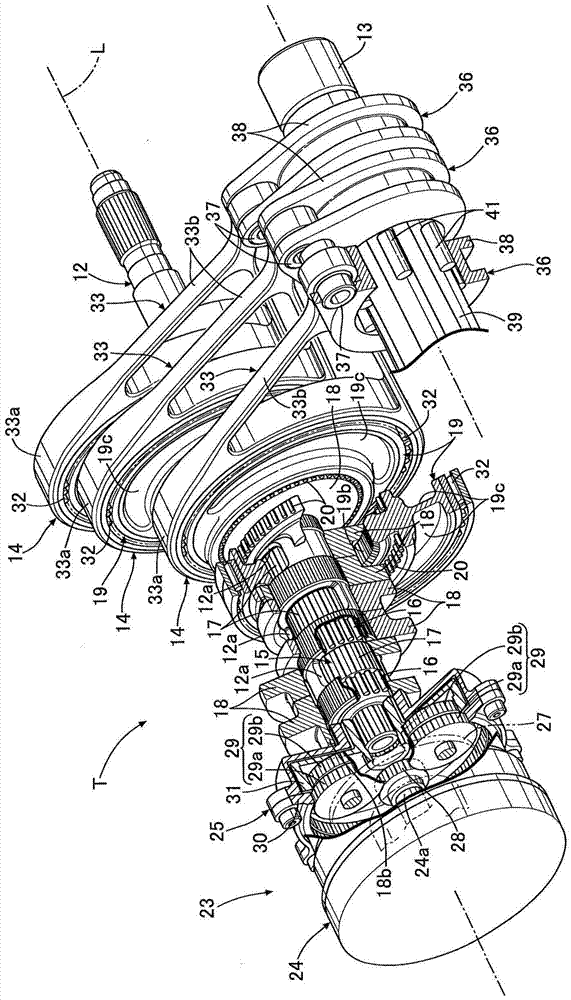

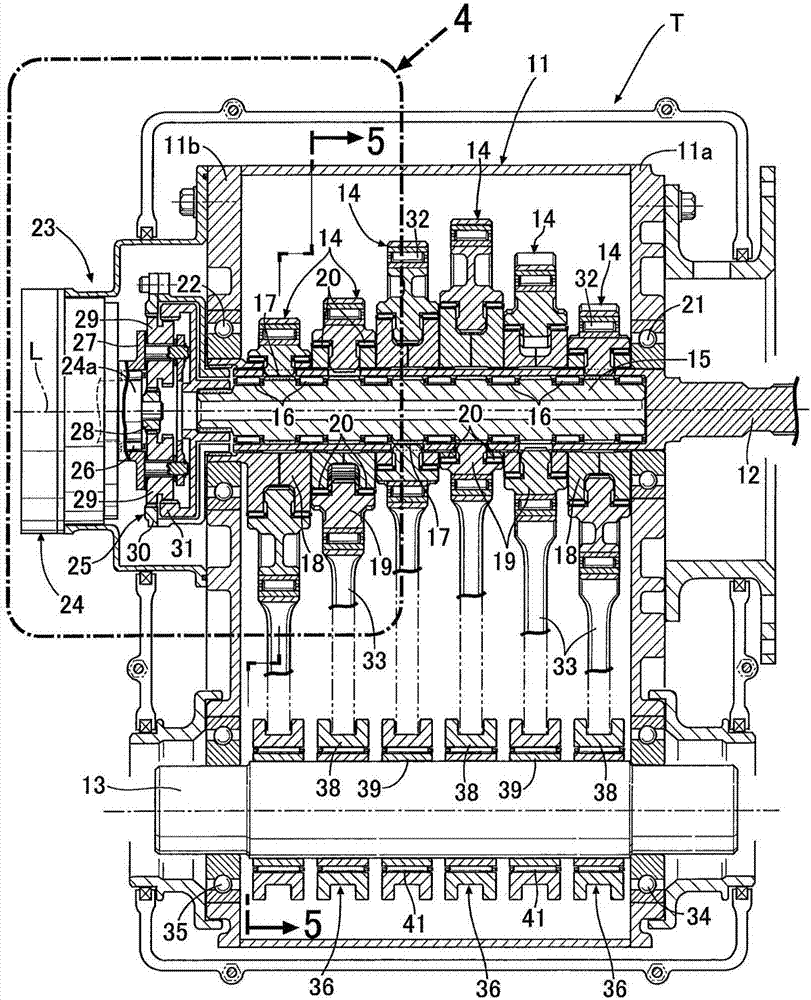

[0062] Below, based on Figure 1 to Figure 21 Embodiments of the present invention will be described.

[0063] like Figure 1 to Figure 5 As shown, the input shaft 12 and the output shaft 13 are supported on a pair of side walls 11a, 11b of the transmission case 11 of the continuously variable transmission T for motor vehicles in parallel with each other, and the rotation of the input shaft 12 connected to the engine P passes through 6 A transmission unit 14, the output shaft 13 and the differential D are transmitted to the drive wheels. A transmission shaft 15 sharing an axis L with the input shaft 12 is relatively rotatably fitted inside the hollow input shaft 12 via seven needle bearings 16 .

[0064] Furthermore, the power transmission device for a vehicle according to the present invention actually includes eight transmission units 14 , but here, for convenience, the number of transmission units 14 will be described as six. The structures of the six transfer units 14 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com