Method for producing blanket, and blanket produced by method

A manufacturing method and technology of quilts, applied to sewing machines for sewing quilts, textiles, papermaking, sewing equipment, etc., can solve the problems of wasting manufacturing time, design limitations, sewing pattern design limitations, etc., and achieve simple and rapid manufacturing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The preferred embodiment of the manufacturing method of the quilt according to the present invention and the quilt manufactured by the method will be described in detail below with reference to the accompanying drawings. When explaining the present invention, detailed description will be omitted when specific well-known functions or configurations make the gist of the present invention unclear. "Consisting" in this specification may further contain other structural elements in addition to other structural elements.

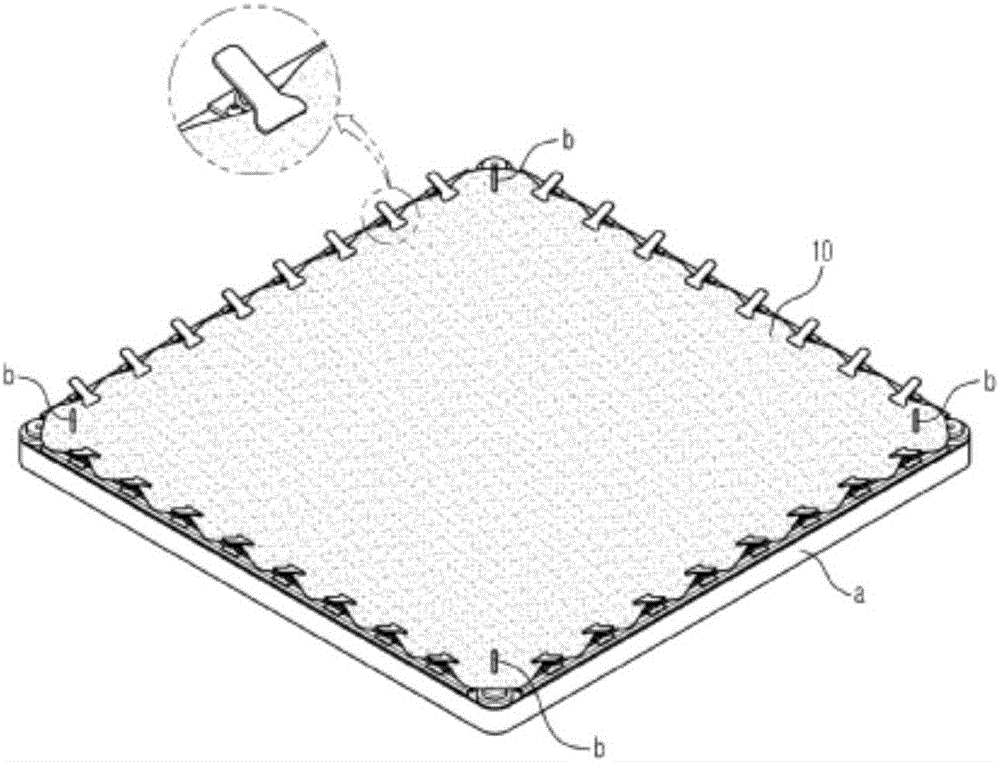

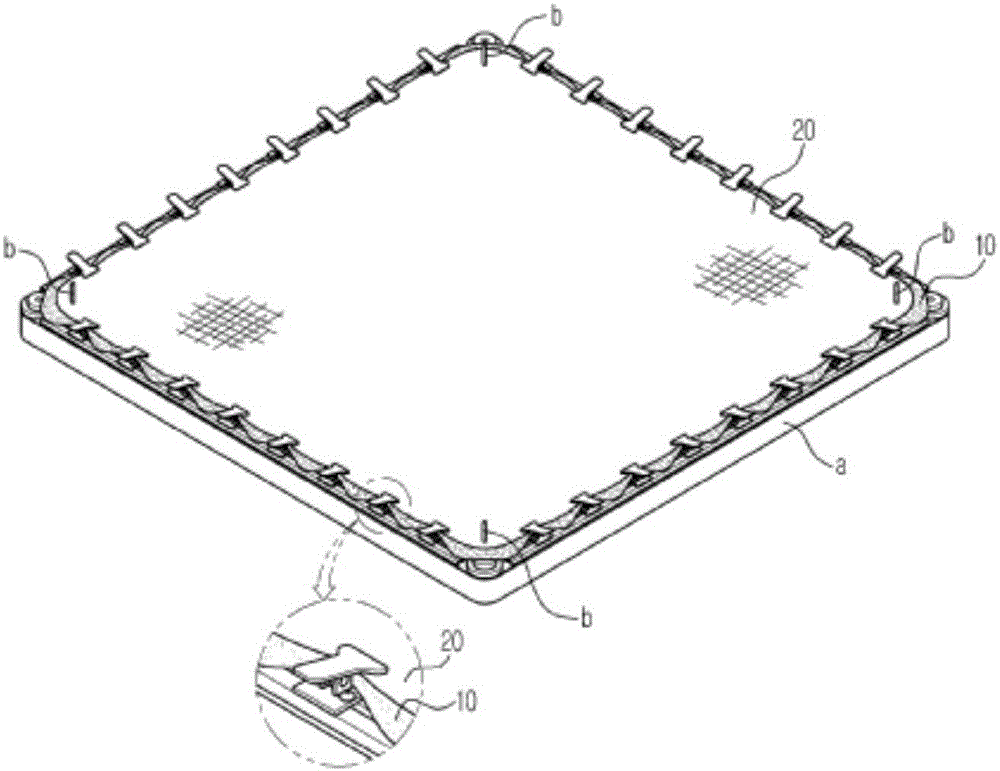

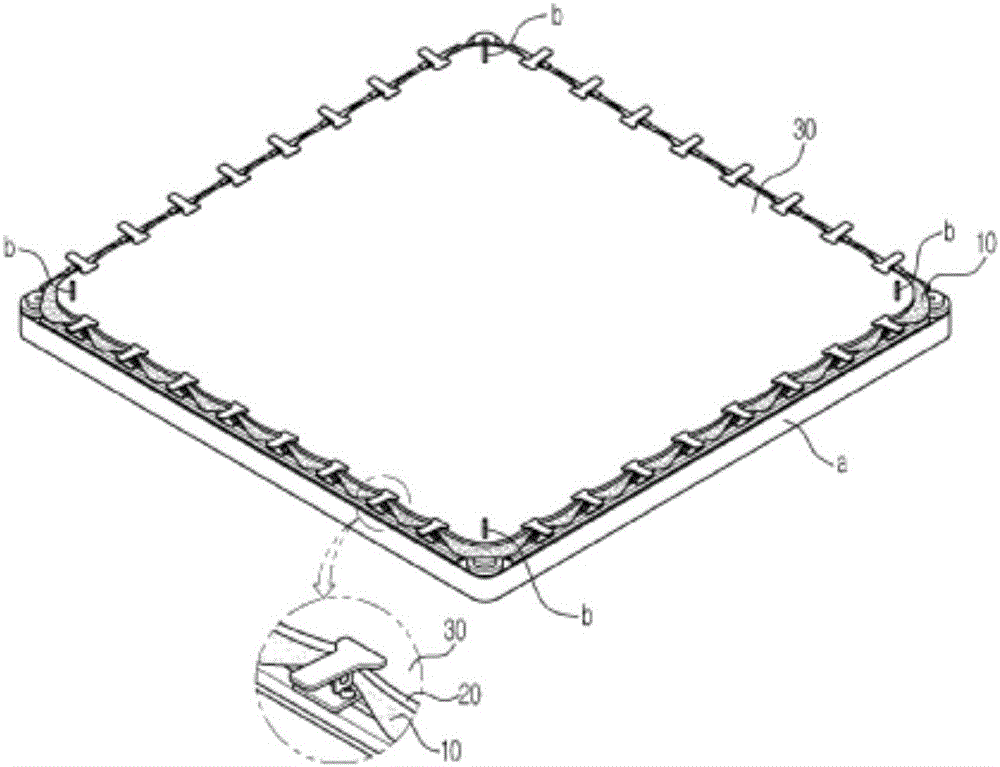

[0037] refer to Figure 1 to Figure 8 , according to an embodiment of the present invention, the manufacturing method of the quilt includes: laying step S1, after unfolding the filling material 10 contained in the quilt, laminating on one side of the filling material 10 to form the top and bottom of the quilt After the first outer skin 20 and the second outer skin 30 are unfolded, the first outer skin 20 and the second outer skin 30; the first sewing step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com