A pulse current assisted internal thread copper tube forming device

A pulse current and forming device technology, applied in the field of extrusion forming, can solve problems such as unfavorable drawing, work hardening of copper tubes, increased internal stress, etc., and achieve the effect of improving elongation and good metal fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

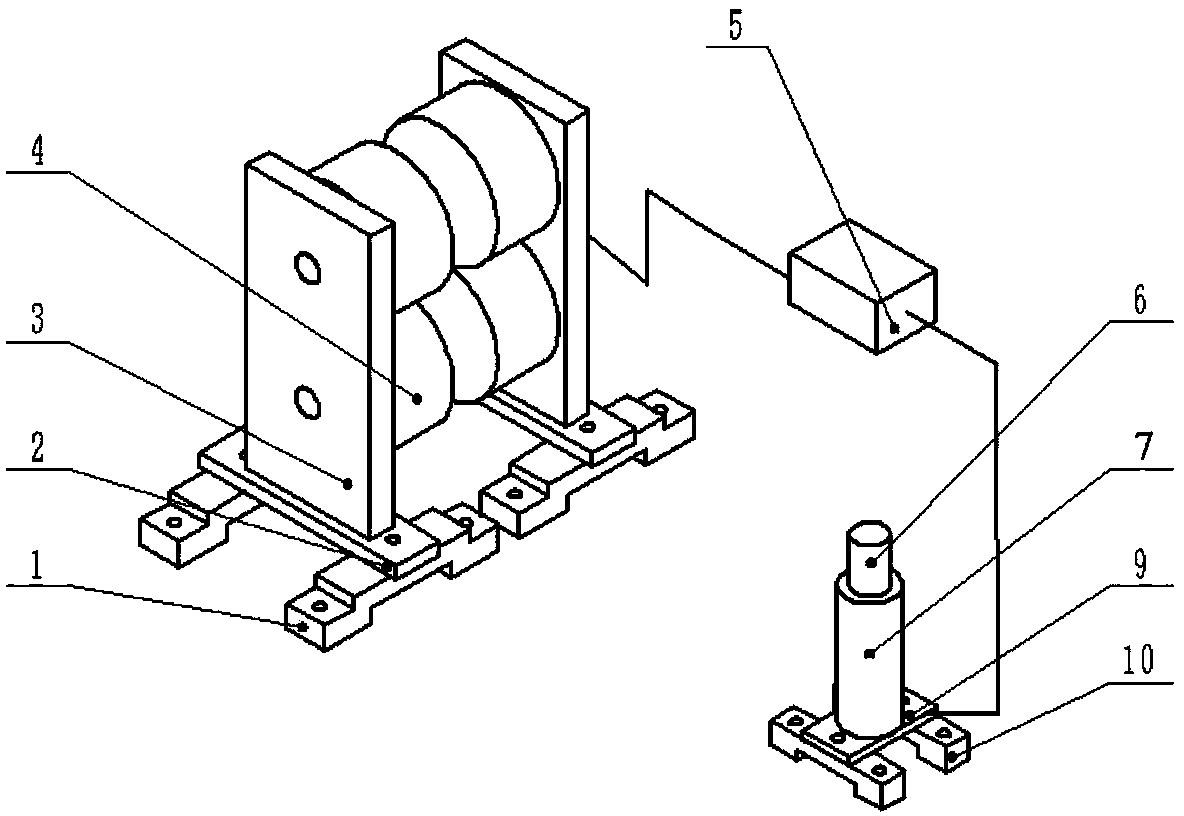

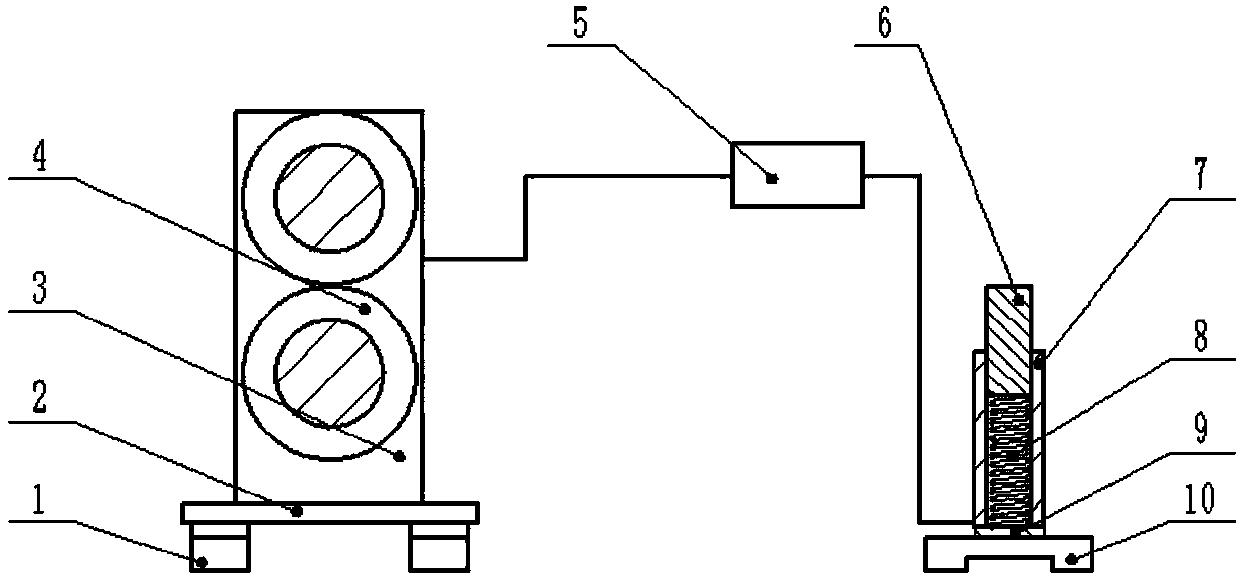

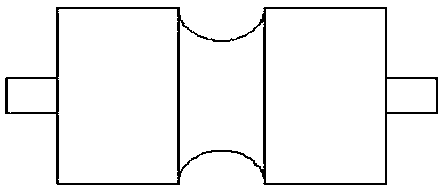

[0017] Such as figure 1 and figure 2 As shown, the positive pole of the power supply 5 that can emit pulsed current is connected to the support frame 3, and the negative pole is connected to the sleeve 7; the tube blank contact device includes four bottom plates 1, two of which form a group, the bottom plate 1 is bow-shaped, and there are fixing holes on both sides. A connection hole is processed in the middle position, and the insulating plate 2 above the two bottom plates 1 is fixedly connected with them by bolts. The longitudinal direction of the insulating plate 2 is perpendicular to the bottom plate 1; The round hole is used to install the rolling element 4, and the structure of the rolling element is as follows image 3 As shown, the middle part of the rolling element is processed with a groove with a semicircular cross section, and the upper and lower semicirc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap