Breaking machine for door strip type sealing rubber strip containing double reinforced steel belts

A technology for sealing rubber strips and steel strips, which is applied to the field of sealing rubber strip breaking machines for door strips containing double-reinforced steel strips, can solve the problems of large floor space, poor use effect of sealing strips, and poor breaking effect, etc. Solve the effects of excessive equipment footprint, significant production area, and high interruption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

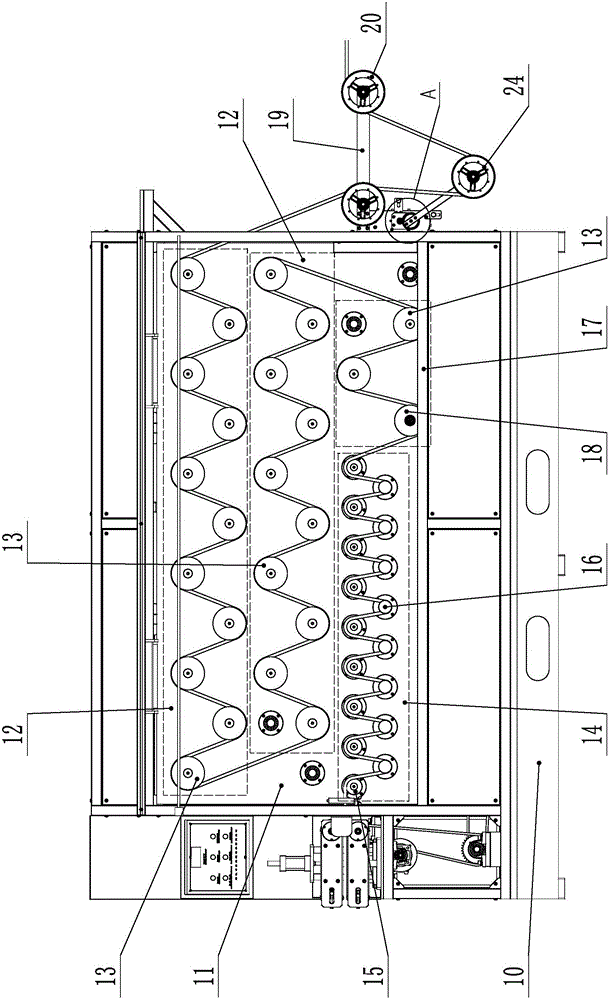

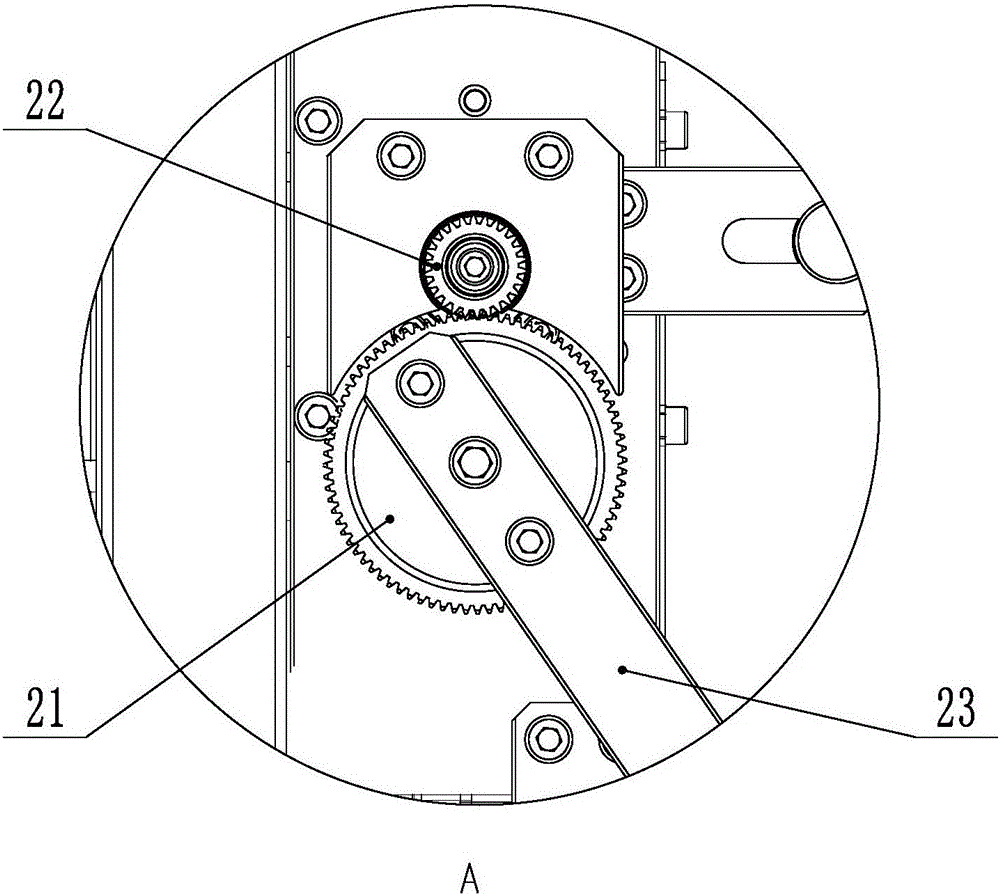

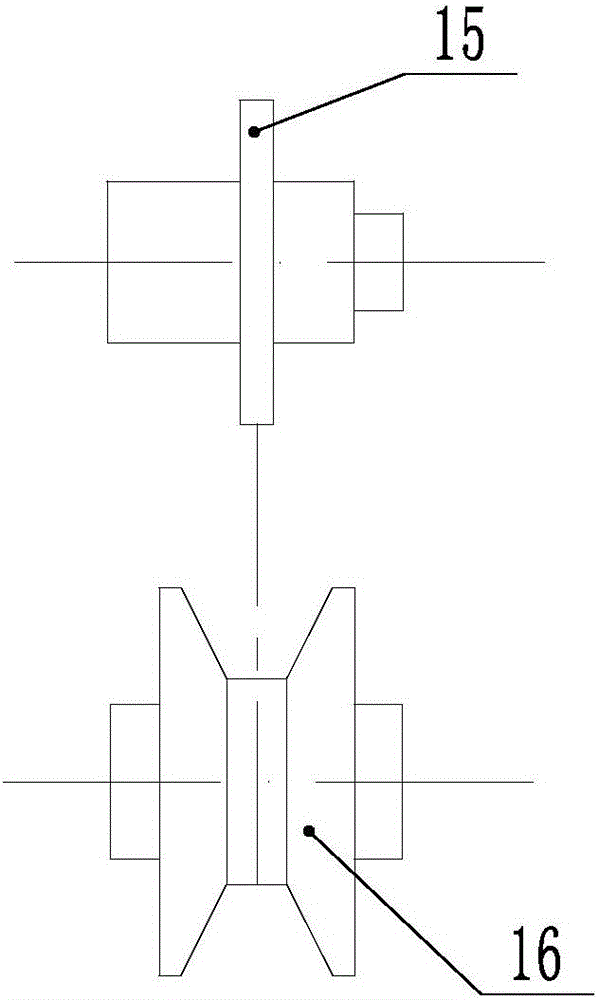

[0022] refer to Figures 1 to 4 , which is a kind of double-reinforced steel strip door strip breaker disclosed by the present invention, a break box 11 is provided on the frame 10, and at least one group of fatigue groups 12 is provided on the upper side of the break box 11 Each group of fatigue groups 12 includes the upper and lower transmission wheels 13 driven by the motor controlled by the controller, and each row is provided with at least one transmission wheel 13, and the upper and lower adjacent transmission wheels 13 are misplaced; in this In the embodiment, the fatigue group 12 is provided with upper and lower groups in the breaking box. This is one of the implementations in this embodiment. In actual use, the number of groups can be set according to actual needs, and It is not limited to the set number of groups in the present embodiment; the outermost drive wheel 13 (i.e. attached figure 1 The leftmost transmission wheel in the upper row of the fatigue group of th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap