Low-gelatinization microwave device

A microwave device and low-paste technology, which is applied in the field of starch or dextrin processing equipment, can solve problems such as uneven heating, product quality differences, and uncontrollable dust, so as to improve product uniformity, reduce dust, and reduce surface gelatinization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

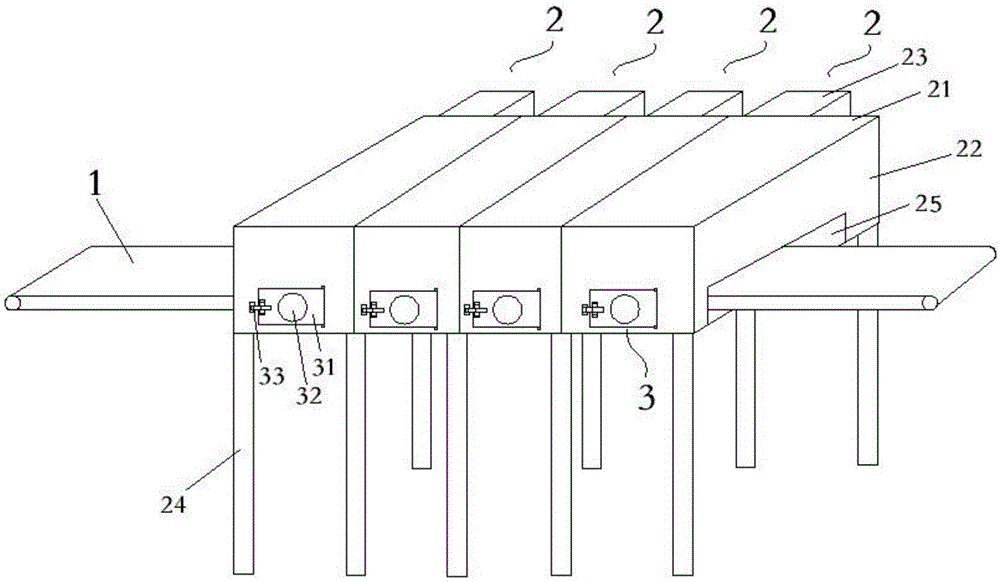

[0014] Such as figure 1 Shown, embodiment 1, a kind of microwave device of low paste rate, comprises: conveyor belt 1, four-section microwave device 2, and described four-section microwave device 2 is serially connected in sequence from left to right, and each section of microwave device 2 comprises: box body 21, baffle plate 22, heating device 23, bracket 24, the two ends of the box body 21 are provided with baffle plates 22, the baffle plate 22 is provided with a through groove 25, and the back side of the box body 21 is provided with a heating device 23, Used to provide heat for the box, the bottom of the box 21 is provided with a bracket 24; the conveyor belt 1 runs through the four-section microwave device 2 sequentially through the through groove 25 on the baffle 22; two adjacent boxes 21 share one Baffle plate 22; the heating temperature of the four-section mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com