Anchoring type light environment-friendly foundation device

A basic device and anchoring technology, applied in basic structural engineering, construction, sheet pile walls, etc., can solve the problems of long transportation and waiting time, segregation, affecting the strength of concrete, etc. Easy to install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

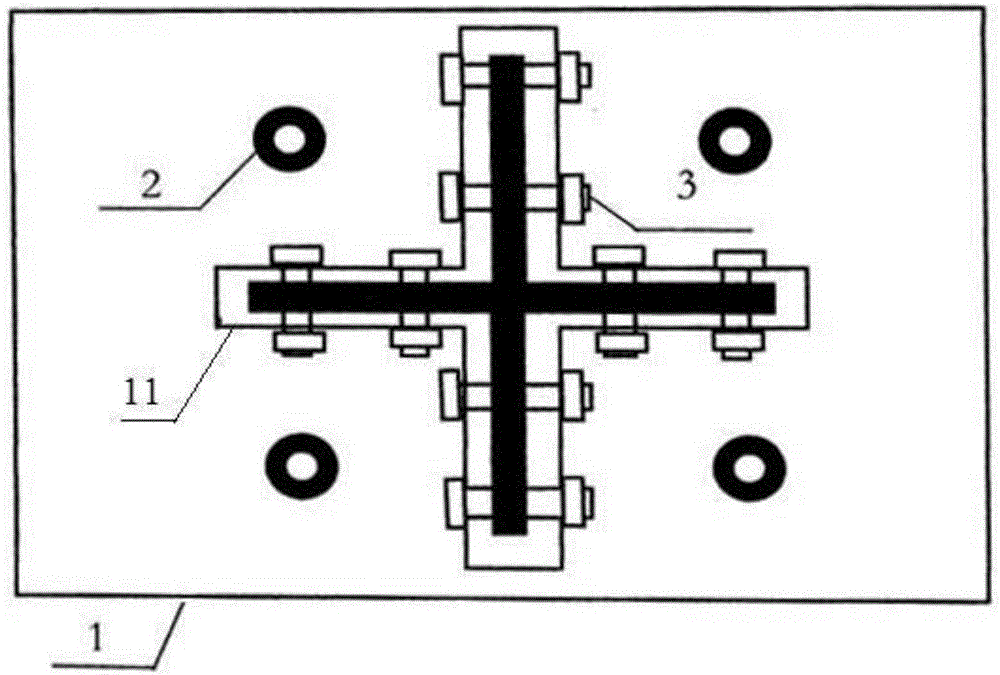

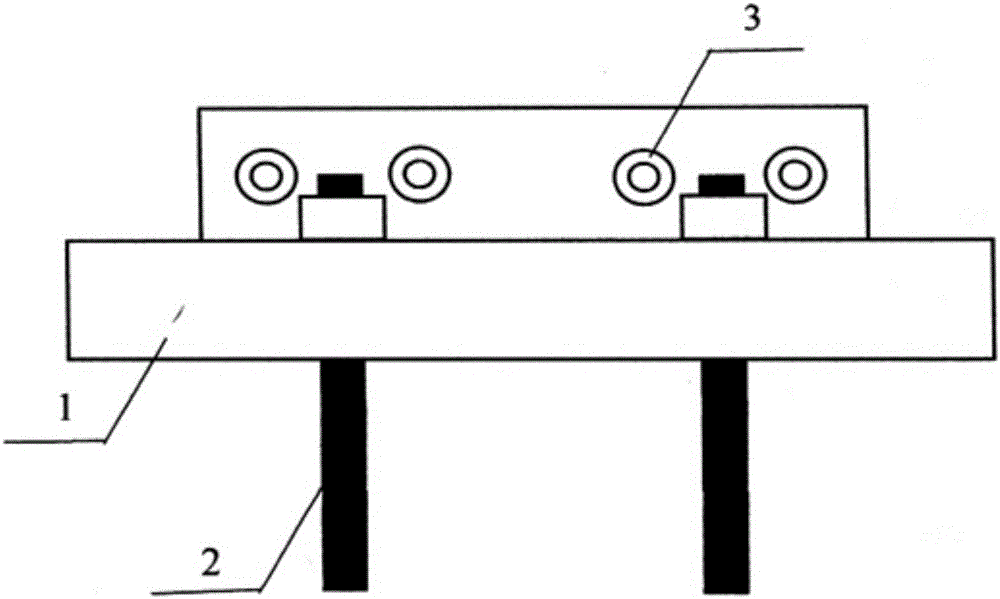

[0021] Such as figure 1 with 2 As shown, an anchored light-duty environmental protection foundation device is composed of a ribbed base 1, a grouting anchor rod 2, and a fixing bolt 3. The ribbed base 1 is composed of a bottom plate and a ribbed beam 11. The ribbed The beam 11 is cross-shaped, and the reinforced rib beam 11 is integrally formed on the upper surface of the bottom plate. The middle part of the reinforced rib beam 11 reserves a column insertion hole and a column reinforcement plate groove, and the side of the reinforced rib beam 11 is reserved for fixing bolt holes; the ribbed base Grouting anchor holes are reserved at the four corners of the seat 1, and the grouting anchor 2 is inserted into the foundation through the reserved grouting anchor holes at the four corners of the ribbed base, and the fixing bolts 3 are inserted into the ribbed base 1 In the fixing bolt holes reserved on the reinforcing rib beam 11.

[0022] A casing is pre-embedded in the grouting ...

Embodiment 2

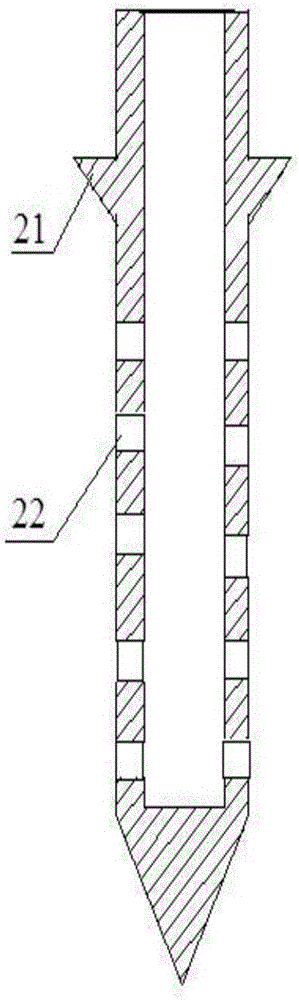

[0039] An anchored light-duty environmental protection foundation device is composed of a ribbed base 1, a grouting anchor rod 2, and a fixing bolt 3. The ribbed base 1 is composed of a bottom plate and a ribbed beam 11, and the ribbed beam 11 is In the shape of a well, the reinforced rib beam 11 is integrally formed on the upper surface of the bottom plate, the middle part of the reinforced rib beam 11 is reserved for column insertion holes and column reinforcement plate grooves, and the side of the reinforced rib beam 11 is reserved for fixing bolt holes; the ribbed base 1 has four corners Reserve grouting bolt holes; image 3 As shown, the grouting anchor rod 2 is a hollow steel pipe, the lower end of the hollow steel pipe is a sealed pointed body, the upper end of the hollow steel pipe is provided with an external thread structure, which is matched with the nut, and the upper outer wall of the hollow steel pipe is provided with a cone-shaped force-bearing structure 21. The...

Embodiment 3

[0042] An anchored light-duty environmental protection foundation device is composed of a ribbed base 1, a grouting anchor rod 2, and a fixing bolt 3. The ribbed base 1 is composed of a bottom plate and a ribbed beam 11, and the ribbed beam 11 is In the shape of a well, the reinforced rib beam 11 is integrally formed on the upper surface of the bottom plate, the middle part of the reinforced rib beam 11 is reserved for column insertion holes and column reinforcement plate grooves, and the side of the reinforced rib beam 11 is reserved for fixing bolt holes; the ribbed base 1 has four corners The grouting anchor rod hole is reserved; the grouting anchor rod 2 is a hollow steel pipe, the lower end of the hollow steel pipe is a sealed pointed body, and the upper end of the hollow steel pipe is provided with an external thread structure, which cooperates with the nut. The upper outer wall of the hollow steel pipe is provided with The cone-shaped stress-bearing structure 21 has hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com