Grafting type positive electrode material precursor as well as preparation method and application thereof

A technology of cathode materials and precursors, which is applied in the field of grafted cathode material precursors and its preparation, can solve the problems of inconsistent electrochemical performance of materials, uneven dispersion of slurry, and poor uniformity of pole pieces, so as to solve the problem of slurry dispersion Unevenness, avoiding the effect of uneven dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

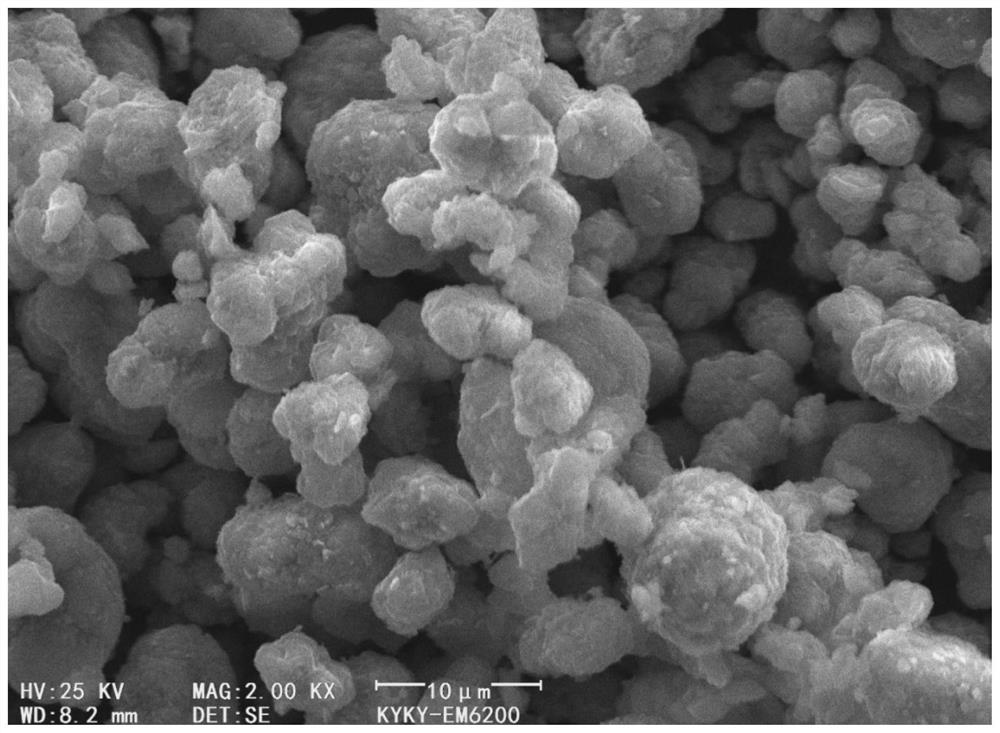

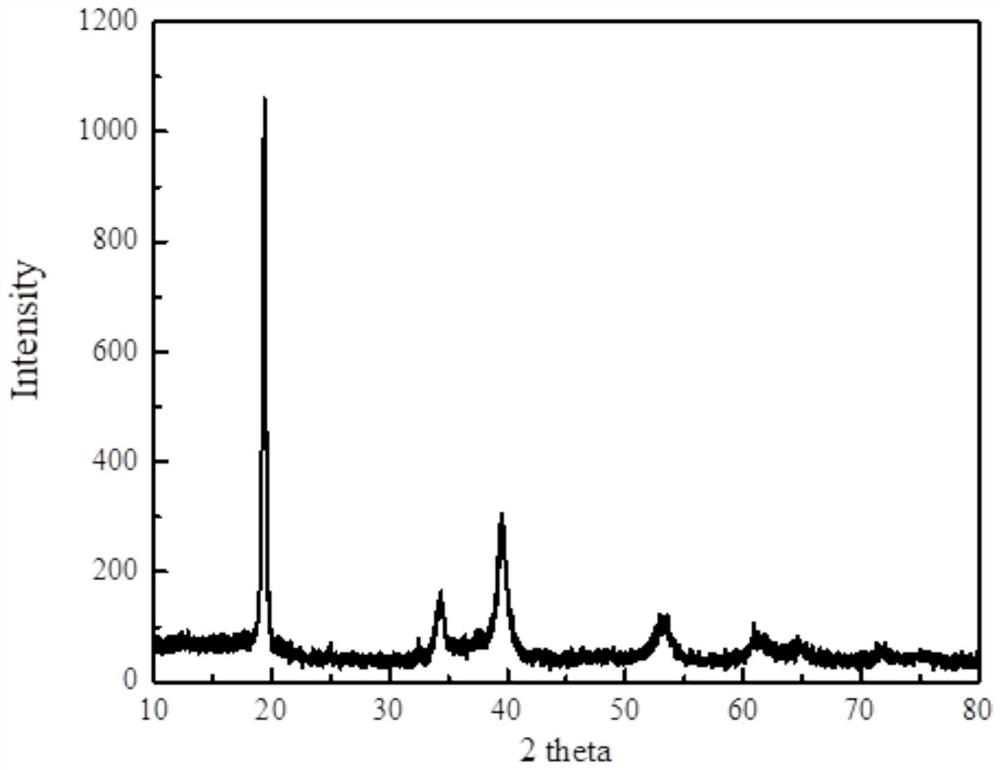

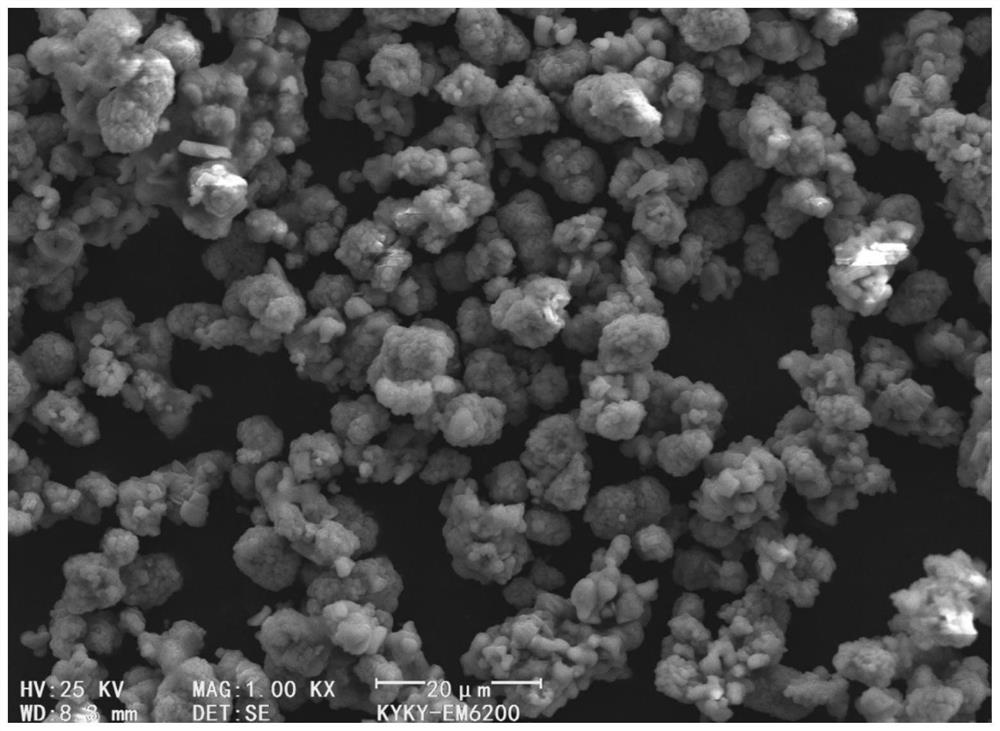

Image

Examples

preparation example Construction

[0046] A second aspect of the present invention aims to provide a method for preparing the grafted positive electrode material precursor, comprising the following steps:

[0047] S1, the aqueous solution containing nickel salt, cobalt salt, manganese salt and Z salt is mixed and reacted with the hydroxide aqueous solution, the pH of the solution in the control reaction process is 10~13, ageing, suction filtration obtains hydroxide type salt A ( OH) 2 ;

[0048] S2, mix and react the aqueous solution containing nickel salt, cobalt salt, manganese salt and Z salt with the carbonate aqueous solution, control the pH of the solution in the reaction process to be 6~9, age, and suction filtration to obtain carbonate type salt BCO 3 ;

[0049] S3, the hydroxide type salt A (OH) 2 with carbonate salt BCO 3 Mixing at 25~70℃ to make slurry; adding the solution for liquid phase reaction to form grafting agent R into the slurry, stirring and reacting for 30~90min, washing and drying to...

Embodiment 1

[0069] A method for preparing a grafted positive electrode material, the structural formula of which is LiNi 0.5 Co 0.2 Mn 0.3 O 2 -LiCoO 2 . The structural formula of the precursor is (Ni 0.5 Co 0.2 Mn 0.3 )(OH) 2 -(Co 0.5 Mn 0.5 )CO 3 -CoCO 3 .

[0070] The preparation method of the grafted positive electrode material precursor includes the following steps:

[0071] S1, (Ni 0.5 Co 0.2 Mn 0.3 )(OH) 2 (i.e. NCM523-OH) precursor preparation: NiSO was formulated in a molar ratio of 5:2:3 4 , CoSO 4 , MnSO 4 aqueous solution (Ni 2+ , Co 2+ , Mn 2+ The total concentration is 2mol*L -1 ) 500mL, marked as solution 1; prepare 4mol*L -1 500mL of NaOH solution, marked as solution 2; solution 1 and solution 2 were added to a five-necked flask reactor with 100mL of deionized water at a speed of about 1mL / min through a peristaltic pump, and the reaction was stirred. 2 protection, and keep the reaction temperature at 30-80 °C and the stirring speed at 500 rpm / min;...

Embodiment 2

[0077] Different from Example 1, the preparation step S3 of the precursor of the grafted positive electrode material.

[0078] S3. Preparation of grafted cathode material precursor: Weigh 40g NCM523-OH and 20g CoCO 3 , dispersed in 60 g of deionized water and stirred at 60 ° C to make a slurry; preparation solution (for generating grafting agent R through liquid phase reaction): including the first solution (CoSO 4 : MnSO 4 The molar ratio is 1:1) the concentration is 2mol / L, the second solution is NaHCO 3 The concentration is 1 mol / L; the first solution and the second solution are pumped into the slurry at the rate of 0.5mL / min and 3.5mL / min respectively, and after the reaction for 30min, the remaining first solution and the second solution are pumped into the slurry Continue to stir and react in the slurry for 30min, wash, filter and dry the slurry to obtain the grafted positive electrode material precursor NCM523-OH grafted CoCO 3 , denoted as NCM523-OH-(Co 0.5 Mn 0.5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com