LED drive circuit capable of realizing multiple output mode setting via code dialing board

A technology of LED circuit and LED drive, which is applied in the direction of electric light source, lighting device, electrical components, etc. It can solve the problems of low efficiency, high error rate, troublesome setting, etc., and achieve the effect of high dimming accuracy and error-free

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

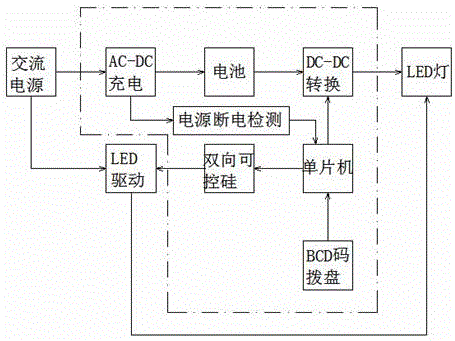

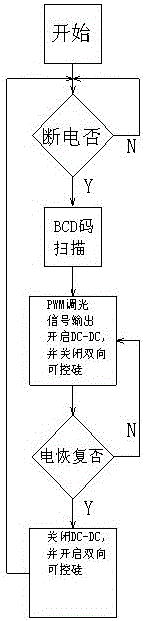

Method used

Image

Examples

Embodiment 1

[0013] The dial uses the current to indicate the desired current value of the LED lamp. The BCD code dial is coded as shown in the table below:

[0014]

[0015] It can also be implemented by inverse code, or scrambling the code.

[0016] The single-chip computer calculates the output PWM modulation pulse according to the output current value corresponding to the code input by the BCD code disc, and sends it to the DC-DC conversion circuit, and the DC-DC conversion circuit controls the output current of the LED lamp.

[0017] The MCU calculates the PWM duty cycle according to the following formula:

[0018]

[0019] If the phase output current to the LED lamp is 100 mA, the duty cycle of the PWM is:

[0020]

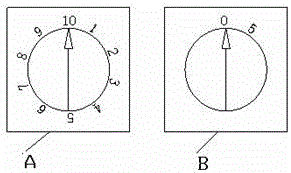

[0021] If the output current is 1000mA, the rotation positions of dial A and B are as follows: image 3 Shown:

[0022] Output current = Disk A points to digital X100+ Disk B points to digital X10

[0023] Then the output current in the above figure = 10X100...

Embodiment 2

[0025] If the output is required to be marked with power, it is the same as the aforementioned code marked with current, and the code marked with power is shown in the table below:

[0026]

[0027] The code wheel marked with power is attached Figure 4 shown.

[0028] According to the output current value corresponding to the code input by the BCD code disc, the single-chip microcomputer calculates the output PWM modulation pulse and sends it to the DC-DC conversion circuit, and the DC-DC conversion circuit controls the dimming of the LED lamp.

[0029] The MCU calculates the PWM duty cycle according to the following formula:

[0030]

[0031] The voltage of the LED is measured by a single-chip microcomputer. For the convenience of measurement, the general DC-DC needs to adopt a boost topology.

[0032] After power-on, the MCU first outputs a minimum 5% duty cycle. After measuring the LED voltage, the PWM duty cycle is calculated by the power set by the user.

[003...

Embodiment 3

[0036] If it is required to mark according to the capacity and discharge time of the battery, the code of the code disc is shown in the table below:

[0037]

[0038] code disc attached Figure 5 shown.

[0039] According to the output current value corresponding to the code input by the BCD code disc, the single-chip microcomputer calculates the output PWM modulation pulse and sends it to the DC-DC conversion circuit, and the DC-DC conversion circuit controls the dimming of the LED lamp.

[0040] The MCU calculates the PWM duty cycle according to the following formula:

[0041]

[0042] 0.9 is the coefficient, the battery voltage is the nominal voltage of the battery, the efficiency is the driving efficiency, the time is the time set on the left figure, 90 minutes corresponds to 1.5, 120 minutes corresponds to 2, the measured LED voltage is the lamp load voltage, and the maximum output current is the driving efficiency. The maximum current that can be supplied.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com