Fishpond with automatic sewage discharging function

A technology of automatic sewage discharge and fish pond, applied in fish farming, application, animal husbandry, etc., can solve the problems of high cost and low efficiency, and achieve the effect of low cost, easy promotion and full sewage discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

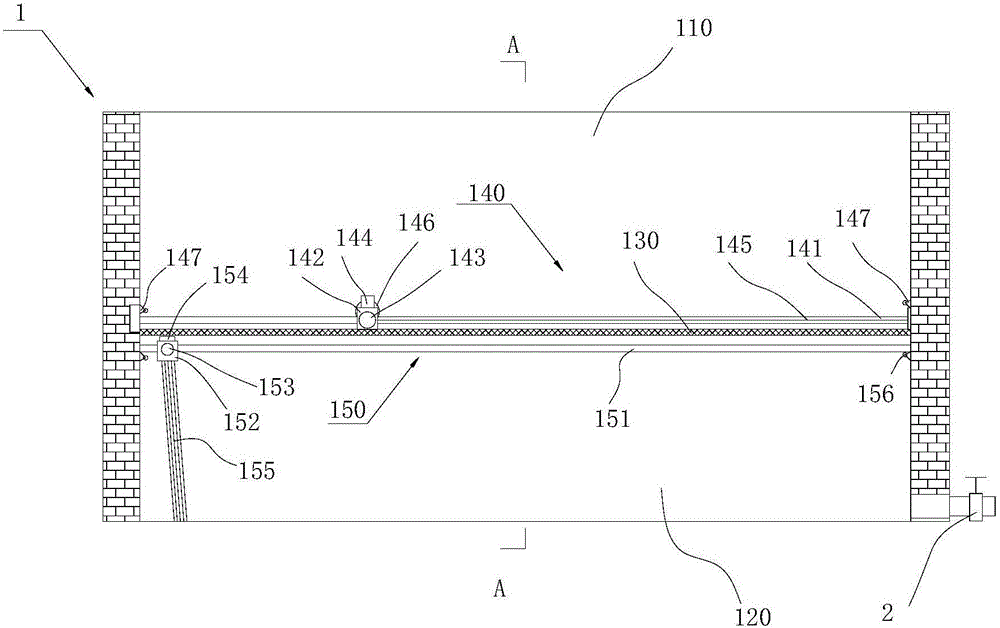

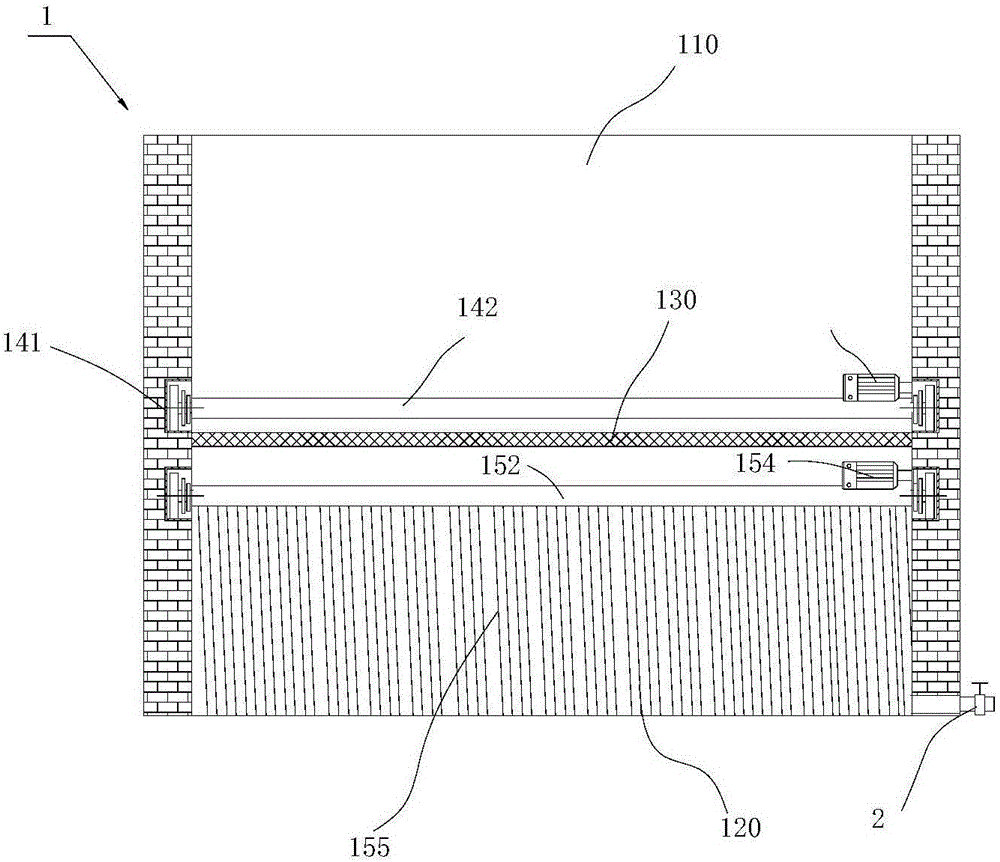

[0019] Example 1, see Figure 1 to Figure 2 , a fish pond with automatic sewage function, comprising a fish pond body 1, the bottom of the fish pond body is provided with a sewage outlet 2; the fish pond body is divided into a fish farming activity unit 110 and a sewage discharge unit 120, the above-mentioned fish farming activity unit The height is not less than 1 / 2 of the height of the fish pond body; if the height is not enough, it will cause more sewage discharge on the one hand, and on the other hand, the density of fish will be too high during the cleaning process, resulting in hypoxia; between the fish farming activity unit and the sewage unit Plane net 130 is provided; the order number of plane net can be selected according to the kind, the size of actual cultured fish, also will meet the smooth passage of residual bait and excrement in addition; The sewage unit is divided into a retractable shielding mechanism 140 of independent chambers; its purpose is to use the shi...

Embodiment 2

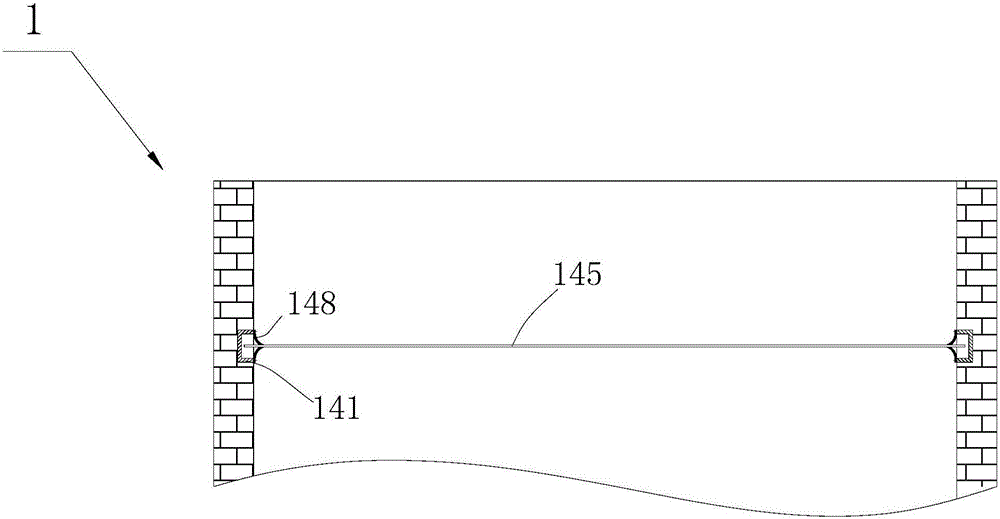

[0025] Example 2, see Figure 4, the retractable shielding mechanism 140 can also adopt the following scheme, including the first slideway 141 fixed on the side wall of the fish farming activity unit in mirror image, the crossbeam 142 connecting the first slideways on both sides, and the two ends of the crossbeam Road wheels 143 are installed, and the road wheels are positioned in the first slideway and move horizontally along the first slideway; the crossbeam 142 is equipped with a submersible motor 143 that drives the crossbeam to move horizontally along the first slideway, and the submersion motor Connect one of the walking wheels 143 of the above-mentioned walking wheels through a transmission, and the submersible motor is connected to a controller that controls the opening or closing of the submersible motor; a flexible bearing plate 145 is installed on the crossbeam 142; the free end of the flexible bearing plate extends to the maintenance The upper part of the fish acti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com