A quick installation device for top drive guide rail

A technology for installing devices and top drive guide rails, which is applied in the direction of hand-held tools and manufacturing tools, can solve the problems of heavy workload, cost, and difficult alignment of pin shaft holes, etc., so as to reduce labor intensity, improve work efficiency, and install Quick and easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation method of the present invention will be described in further detail below in conjunction with the accompanying drawings.

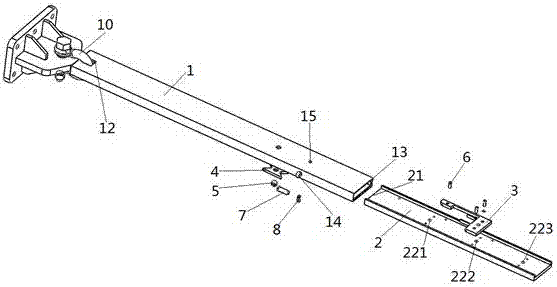

[0015] refer to figure 1 , 2 , a quick installation device for the top drive guide rail, refers to the installation device for the adjustment plate and the first section of the guide rail connected with the crane, and is a device with ingenious structure and simple and quick installation.

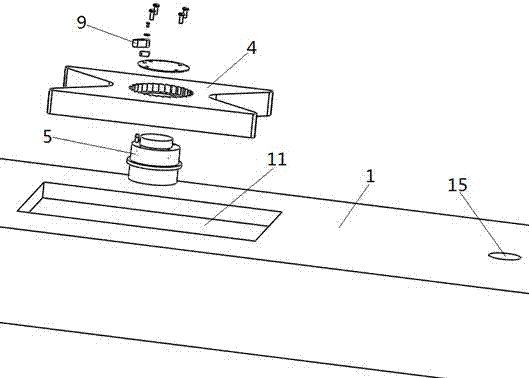

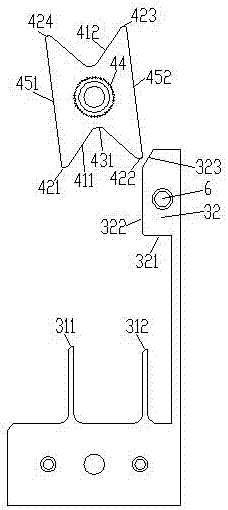

[0016] The present invention includes a guide rail, which includes an outer guide rail 1 and an inner guide rail 2; the outer guide rail 1 is a hollow body on which a ratchet limit guide device is installed, and the inner guide rail 2 is installed on the inner guide rail 2 to make the ratchet limit guide device move. device; when the inner guide rail 2 is inserted into the outer guide rail 1, the top block device contacts with the ratchet limit guide device so that the connecting pin holes 15 of the outer guide rail 1 and the inner gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com