High-reliability conveying trolley structure for construction field

A construction site and transport trolley technology, which is applied to trolleys, motor vehicles, single-axis trolleys, etc., can solve problems such as inability to adapt to complex terrain, injury to cart personnel, and scattered goods, so as to increase the number of people and slow down the tendency of inclination , Good supporting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

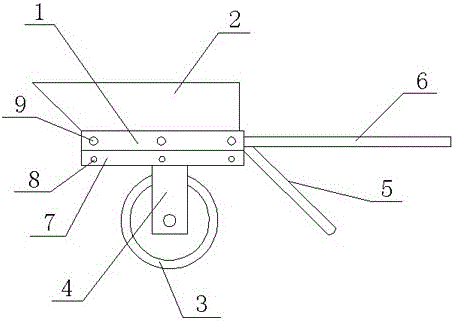

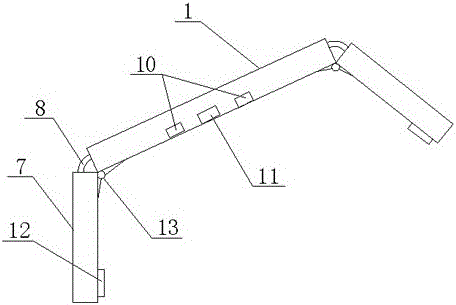

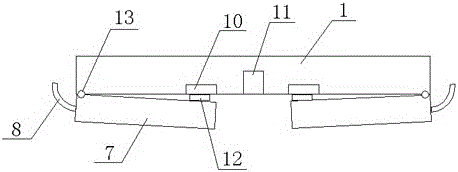

[0023] Such as Figure 1~Figure 4 As shown, a high-reliability transport trolley structure for a construction site described in this embodiment includes a vehicle board 1, a vehicle bucket 2, a single wheel 3, a support rod 5 and a handlebar 6, and the vehicle bucket 2 is located on the vehicle panel. 1, the single wheel 3 is fixed below the vehicle panel 1 through the wheel plate 4, and the support rod 5 and the handlebar 6 are fixed on the same end of the vehicle panel 1, and also include anti-falling devices arranged on both sides of the vehicle panel 1, so The anti-falling device can be opened downwards and stowed toward the bottom of the vehicle panel 1 .

[0024] The anti-falling device of this embodiment includes a support part and a control part, the support part includes a support plate 7, and the support plate 7 is hinged on the side of the vehicle plate 1 parallel to the direction of movement of the trolley;

[0025] The control part of the present embodiment inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com