Equipment that can increase the stability of circular cutting and forming for electrical instrument panel maintenance

An instrument panel and stability technology, which is applied in the field of equipment to increase the stability of circular cutting and forming during the maintenance of power instrument panels, can solve the problems of poor glass cutting quality, shortened cutting time, uneven curvature, etc. Shortened cutting time and uniform radian effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

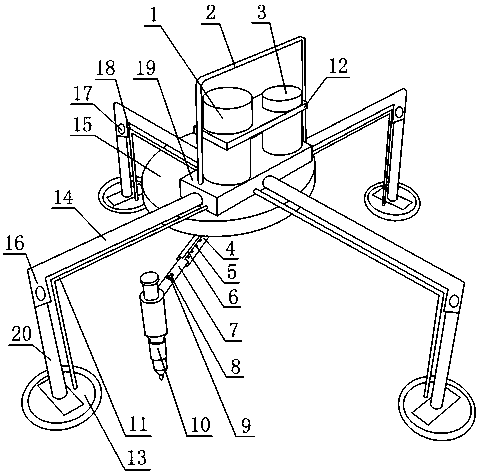

[0013] Such as figure 1 As shown, the equipment that can increase the stability of the peripheral cutting and forming during the maintenance of the electric instrument panel includes a support platform 15, a mounting plate 19 is arranged above the support platform 15, and the bottom surface of the mounting plate 19 is fixed on the top surface of the support platform 15 , the center of the mounting plate 19 and the center of the support table 15 are arranged on the same plumb vertical line, the mounting plate 19 is provided with a motor 1 and an air pump 3, the motor 1 and the air pump 3 are fixed with the mounting plate 19, the motor 1 is connected with a rotating shaft, The rotating shaft passes through the center of the mounting plate 19 and the support table 15, the centerline of the rotating shaft is parallel to the vertical line, and the rotating shaft can rotate around its axis. A telescopic arm is arranged below the support table 15, and the telescopic arm is fixed to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com