Method for evaluating filling characteristics of filling coal mining hydraulic supports

A technology of hydraulic support and filling coal mining, which is applied to pillars/supports, mining equipment, earthwork drilling and mining, etc., and can solve the problems of large manpower and material resources, waste of time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

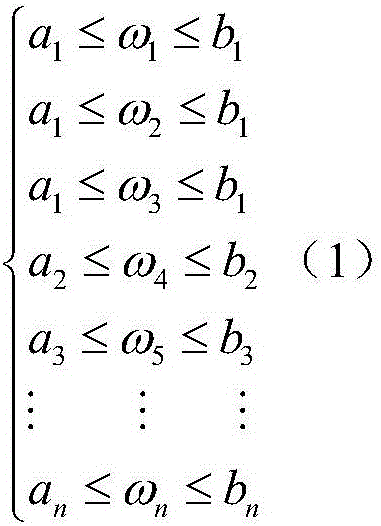

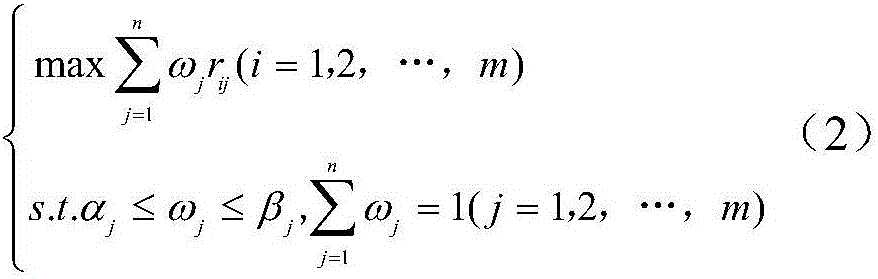

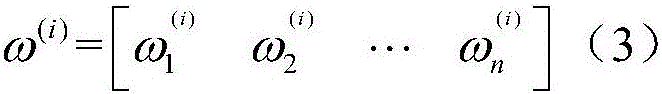

Method used

Image

Examples

Embodiment 1

[0101] Embodiment 1: An evaluation system of filling coal mining hydraulic support, which is specifically implemented as follows: A. Analysis of geological data; B. Preliminary selection of hydraulic support frame type; C. Determining the primary selection scheme of the foundation; D. Determination of filling coal mining Evaluation index of filling characteristics of hydraulic support; E. Use Pro / E, Solidworks or CATIA and other three-dimensional software to build a skeleton model, and perform motion simulation to obtain a filling characteristic evaluation matrix; F. Comprehensive evaluation of multiple indicators to determine the optimal solution.

[0102] 1. Step A: Analyze geological data

[0103] The 7203W working face of Zhaizhen Mine has a vertical depth of 517.1~565.8m, corresponding to the ground elevation of +177.1~+181.2m, underground elevation of -340.0~-384.6m, an average strike length of 286m; an average inclination length of 92.8m, and a working face coal seam thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com