A filling characteristic evaluation method of coal mining hydraulic support

A hydraulic support and characteristic technology, applied in pillars/supports, mining equipment, earthwork drilling and mining, etc., can solve the problems of large manpower and material resources, waste of time, etc., and achieve the effect of reducing design and development time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

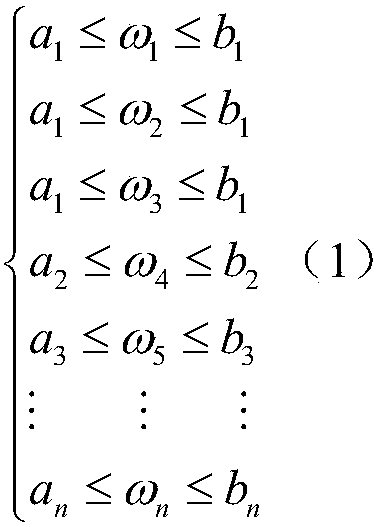

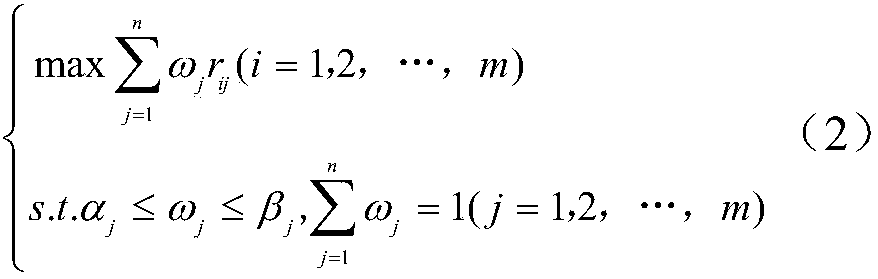

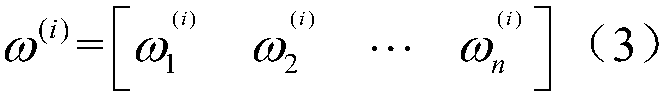

Method used

Image

Examples

Embodiment 1

[0101] Embodiment 1: An evaluation system of filling coal mining hydraulic support, which is specifically implemented as follows: A. Analysis of geological data; B. Preliminary selection of hydraulic support frame type; C. Determining the primary selection scheme of the foundation; D. Determination of filling coal mining Evaluation index of filling characteristics of hydraulic support; E. Use Pro / E, Solidworks or CATIA and other three-dimensional software to build a skeleton model, and perform motion simulation to obtain a filling characteristic evaluation matrix; F. Comprehensive evaluation of multiple indicators to determine the optimal solution.

[0102] 1. Step A: Analyze geological data

[0103] The 7203W working face of Zhaizhen Mine has a vertical depth of 517.1~565.8m, corresponding to the ground elevation of +177.1~+181.2m, underground elevation of -340.0~-384.6m, an average strike length of 286m; an average inclination length of 92.8m, and a working face coal seam thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com