LED (Light Emitting Diode) lamp

A technology of LED lamps and LED light sources, applied in lighting devices, cooling/heating devices of lighting devices, light sources, etc., can solve the problems of difficult replacement of LED light source structures, cumbersome and complicated replacement and maintenance work, unfavorable inspection and maintenance work, etc., to achieve safety High performance, convenient and fast assembly process, convenient maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

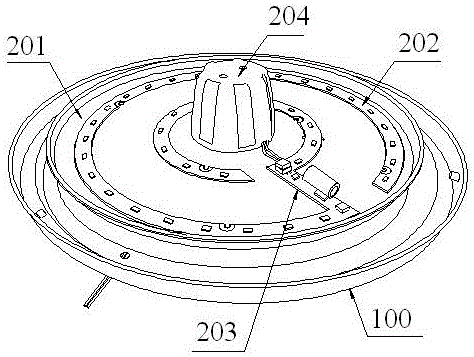

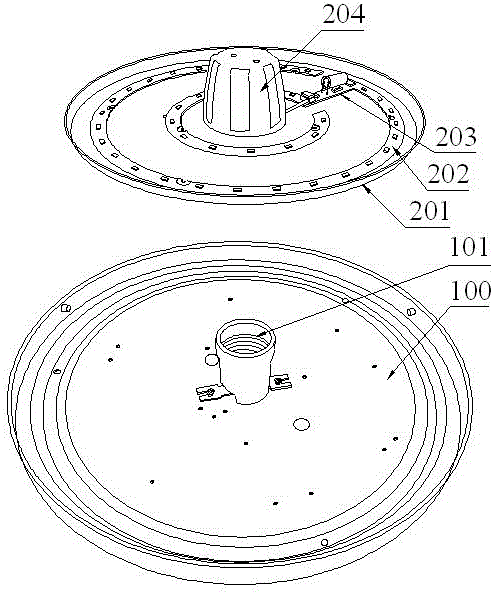

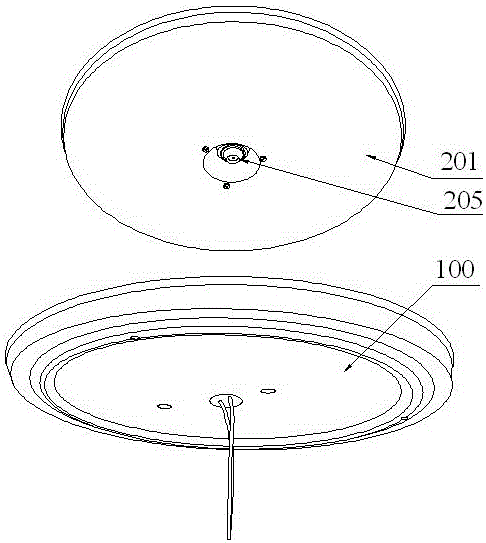

[0015] refer to Figure 1 to Figure 3 , an embodiment of an LED lamp of the present invention is proposed, including an installation chassis 100, a lamp holder 101 fixed on the installation chassis 100, a light source body installed and fixed in the lamp holder 101 and energized, and a cover arranged on the light source body The light-transmitting cover, the light source body includes a light source chassis 201, an LED light source structure 202 fixed on the light source chassis 201, a driving circuit board 203 electrically connected to the LED light source structure 202, and a light source chassis 201. Insert the insulating sleeve 204 of the lamp base 101 , the lamp cap nut 205 which is arranged in the insulating sleeve 204 and is electrically connected with the drive circuit board 203 and can be screwed into the lam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com