Portal frame type automotive headlamp detection equipment

A technology for automobile headlights and testing equipment, which is applied in the direction of testing the alignment of automobile headlights, testing optical performance, etc., can solve problems such as track deformation, inaccurate testing data, and inability to repair.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

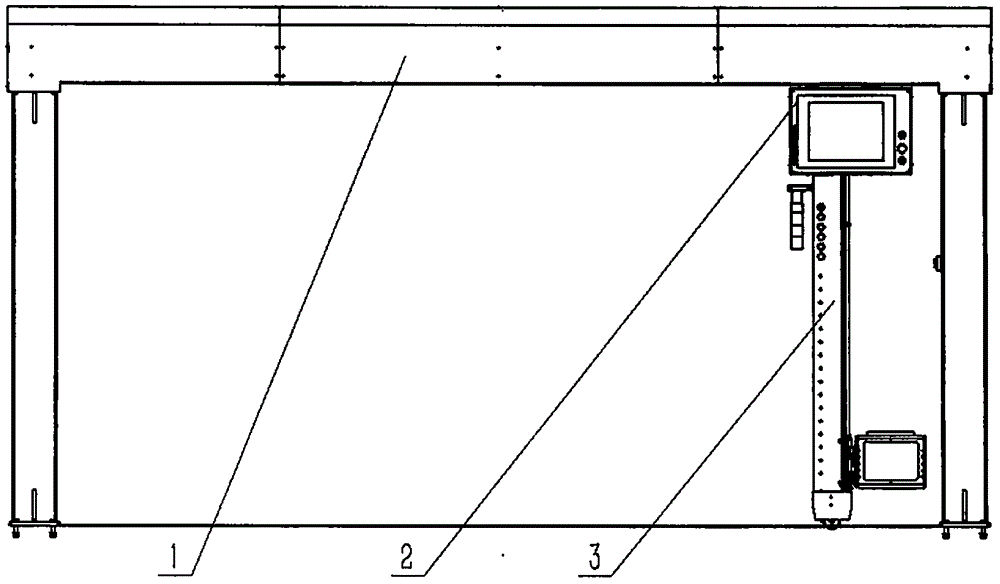

[0014] Such as figure 1 As shown, the whole automatic vehicle headlight detection equipment consists of three parts: 1-gantry frame assembly, 2-slotted trolley, 3-vertical guide unit.

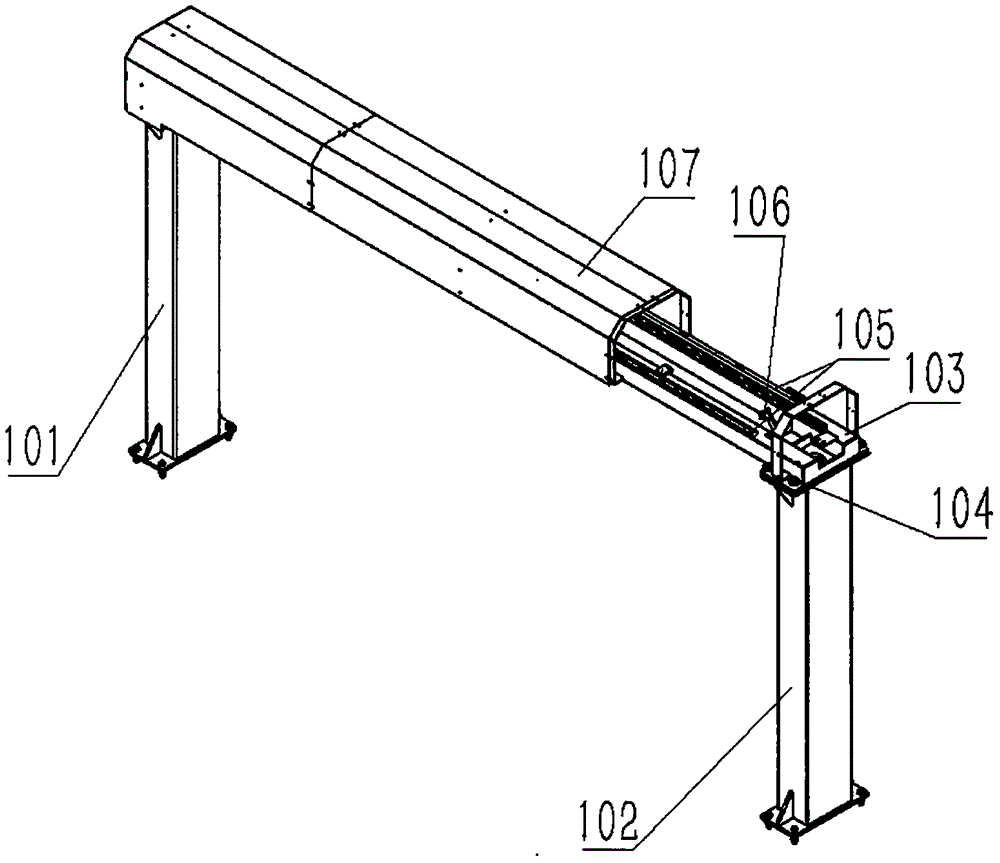

[0015] 1-In the gantry frame assembly, 101-the left pillar and 102-the lower end surface of the right pillar is fixed to the ground, and the upper end surface is connected to 103-the main beam; 104-adjusting bolts to adjust the parallelism between 103-the main beam and the ground; 105-the linear track is fixed on 103-on the main beam; 106-limiting device is installed on the 103-main beam to prevent the 2-groove trolley from rushing out of the track accidentally; 107-dust cover is installed on the 103-main beam.

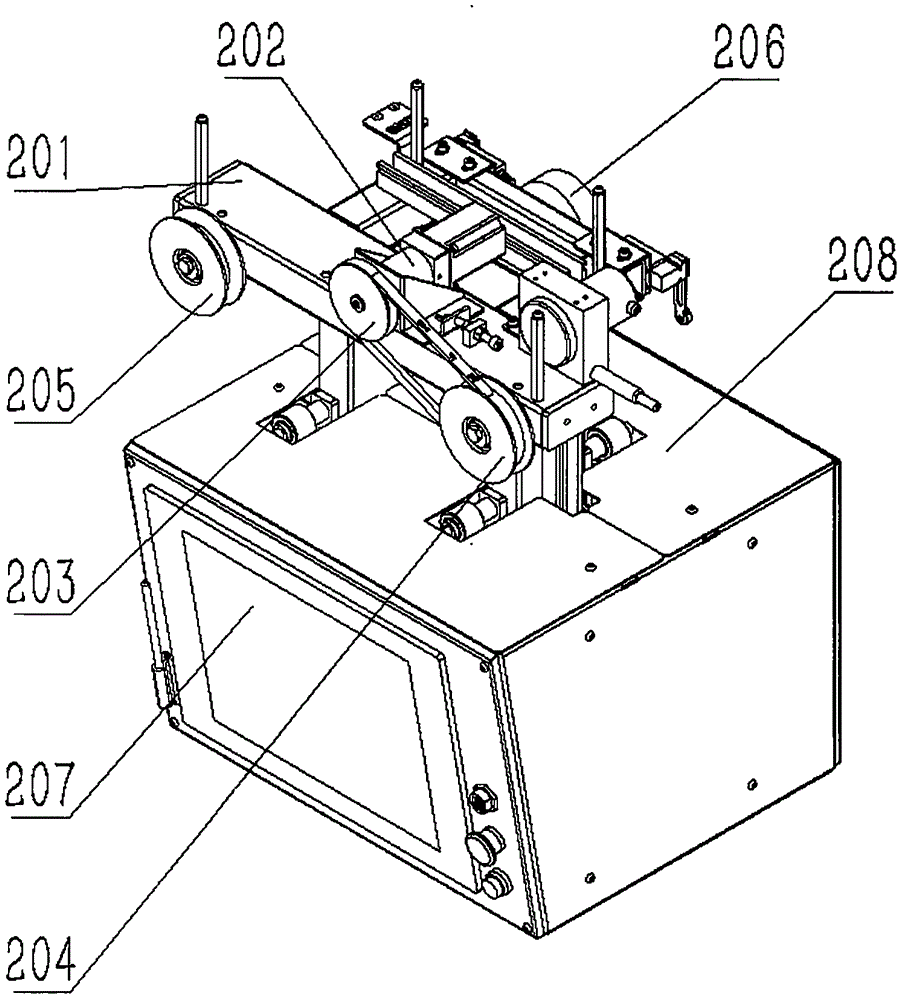

[0016] 2-The sheave trolley is installed on the 1-gantry frame assembly and can move left and right; 201-the left side of the base frame is installed with 204-drive sheave and 205-driven sheave, and the right side is 206-driven flat wheel; The upper surface of 201-base frame is rectan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com