An anti-crack edge banding process for pet handle-free door panels

A door panel and process technology, which is applied in the field of anti-crack edge sealing technology to achieve the effect of improving connection firmness and reducing cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

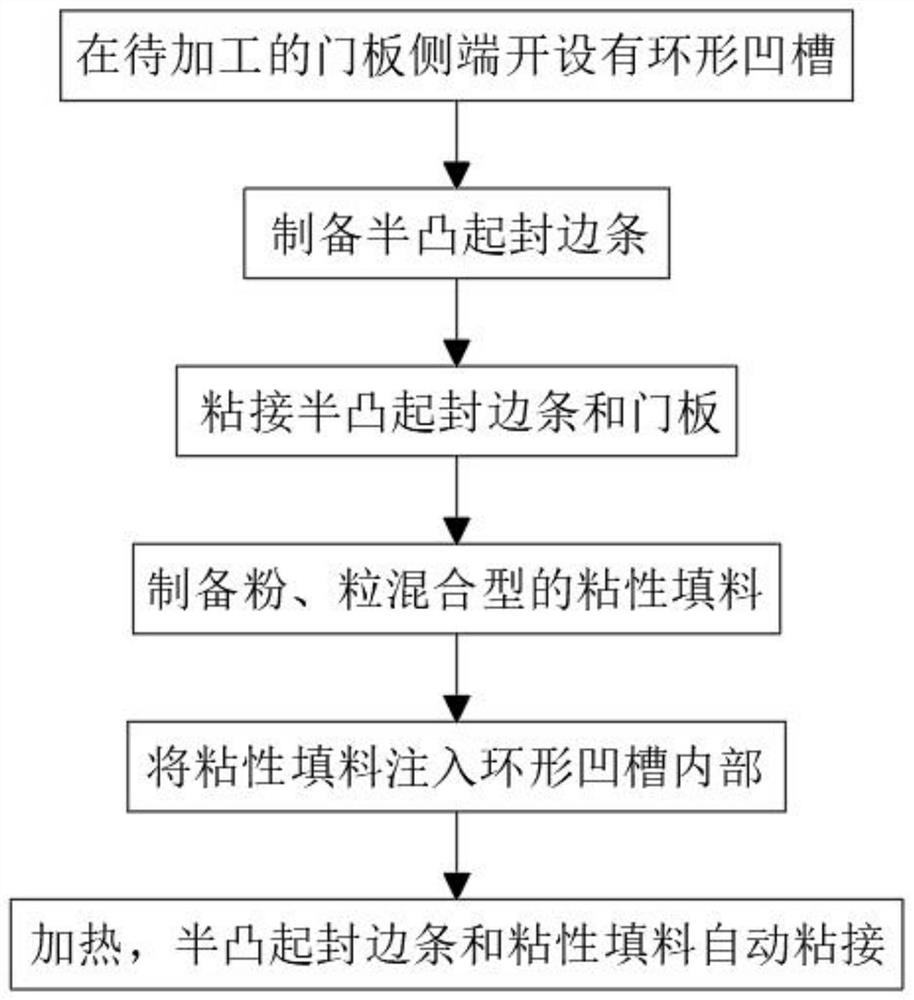

[0047] See figure 1 with figure 2 A anti-cracking edge process of PET free handle doors, including the following steps:

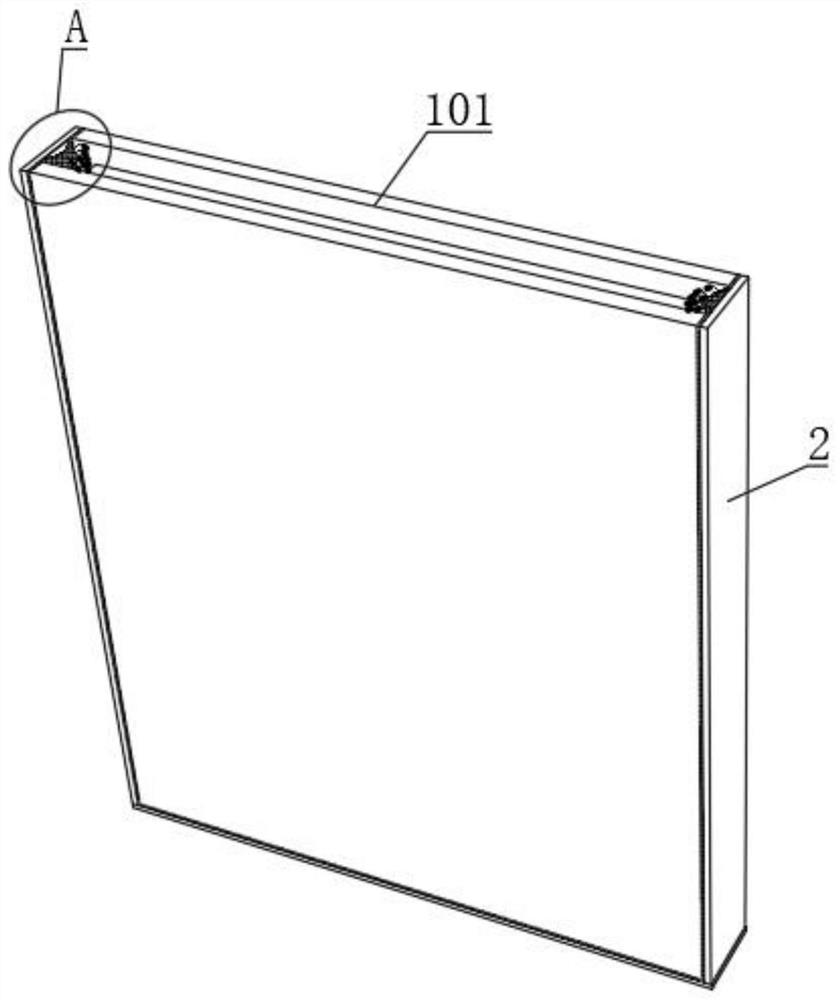

[0048] S1, an annular groove 101 is opened on the side end of the door panel to be processed.

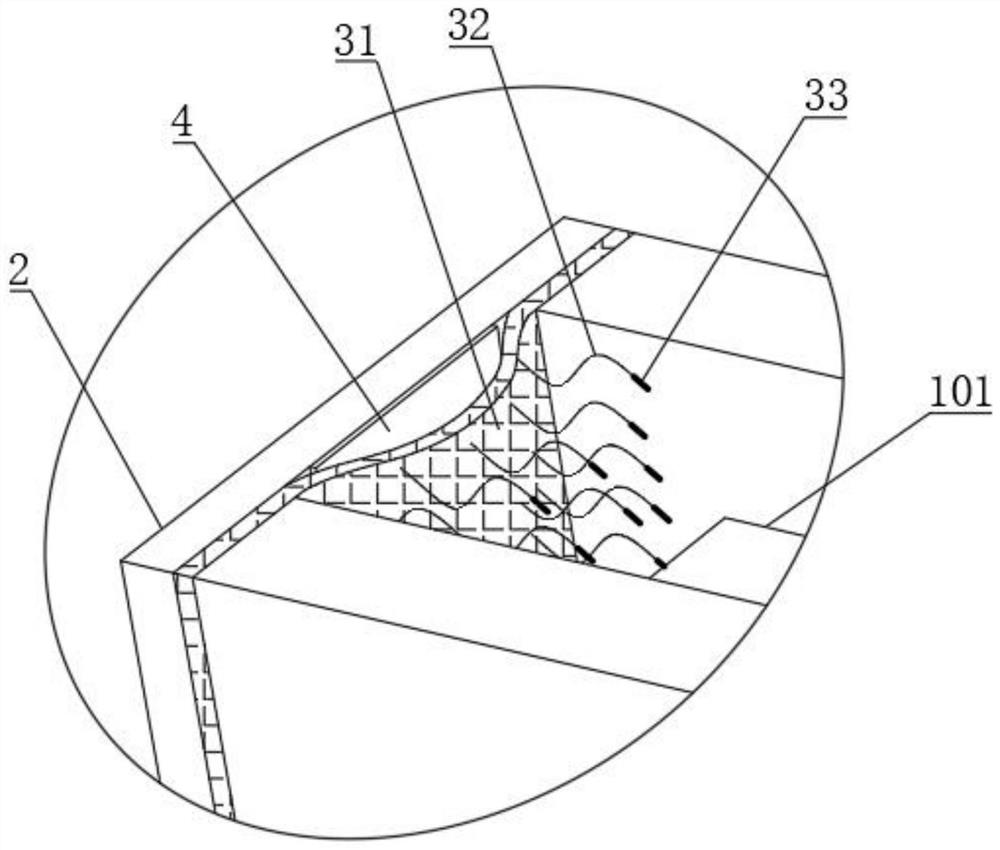

[0049] S2, combine the PVC seal edge 2 and the wrapped wire mesh cloth to make a semi-bump edge;

[0050] S3, a hot melt glue of the molten state is applied to the door panel side surface, and the semi-raised edge bond is bonded to the door panel side end by hot melt adhesive, wherein the semi-bump edge strip performs the groove of the annular groove 101. Closed, and the convex portion on the semi-bump edge strip is located inside the annular groove 101;

[0051] S4, preparation of powder, grain mixed viscous filler;

[0052] S5, the viscous filler is injected inside the annular groove 101, and the annular groove 101 is filld;

[0053] S6, heating the door panel side end to secure the semi-bump edge and the viscous filler to complete the closure process.

[0054] See...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com