Prosthetic Knee

A knee joint and joint technology, applied in the field of prosthetic knee joints, can solve the problems of geometric atresia of the joint system, complex structure of the prosthetic knee joint, etc., and achieve the effect of no maintenance and low noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

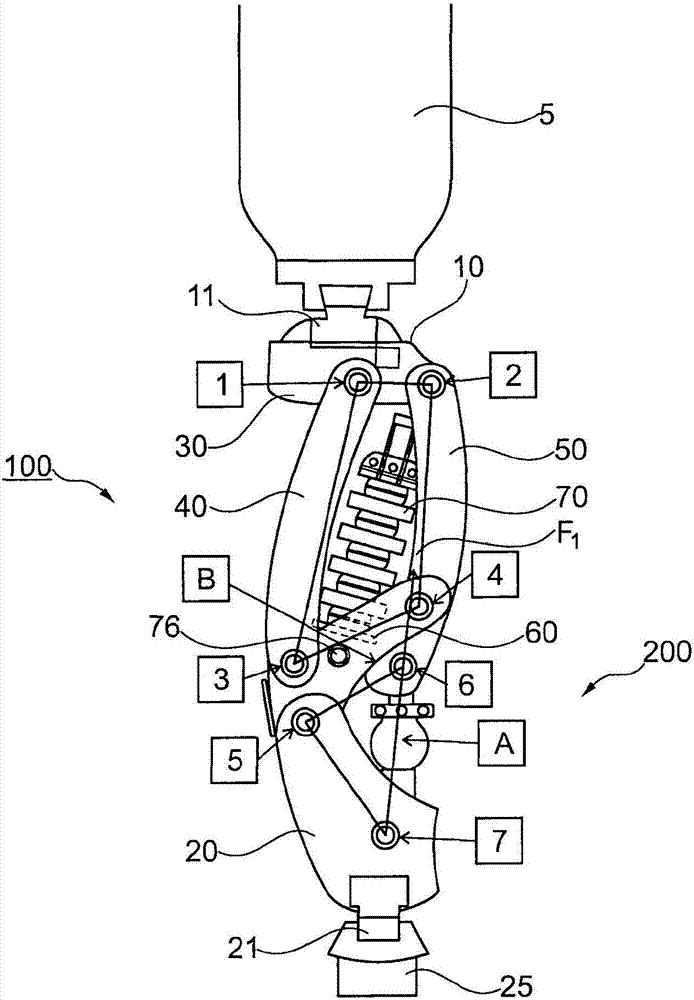

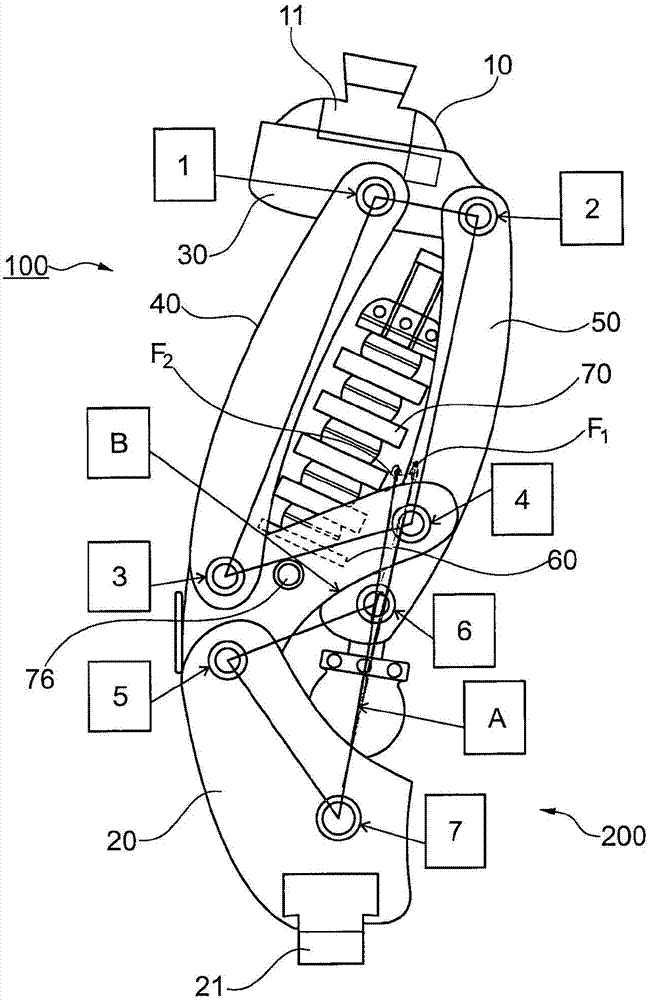

[0021] figure 1 The embodiment of the prosthetic knee joint shown in has an upper part 10 on which a fastening device 11 configured as a joint hanger for a telecentric prosthetic part is arranged, for example for fastening the prosthetic knee joint to the thigh Tube or thigh tube. The fastening device 11 can be screwed into the upper part 10 or can be integrally formed thereon. The first joint part 30 of the four-part joint system 100 can be arranged or formed on the upper part 10 . The proximal, substantially horizontally oriented joint part 30 has an anterior pivot axis 1 and a posterior pivot axis 2 . A front joint member 40 is pivotally supported on the front pivot shaft 1 , and a rear joint member 50 is pivotally supported on the rear pivot shaft 2 . The proximal end of the front joint part 40 is thus pivotably connected via the pivot axis 1 and the proximal end of the rear joint part 50 via the pivot axis 2 to the upper part 10 or to the proximal joint part 30 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com