Multi-part, sprung rail wheel

A track wheel, multi-piece technology, applied to wheels characterized by track running parts, web-type wheels, wheels, etc., can solve problems such as poor strength characteristics, large diameter, and limited possibility of loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

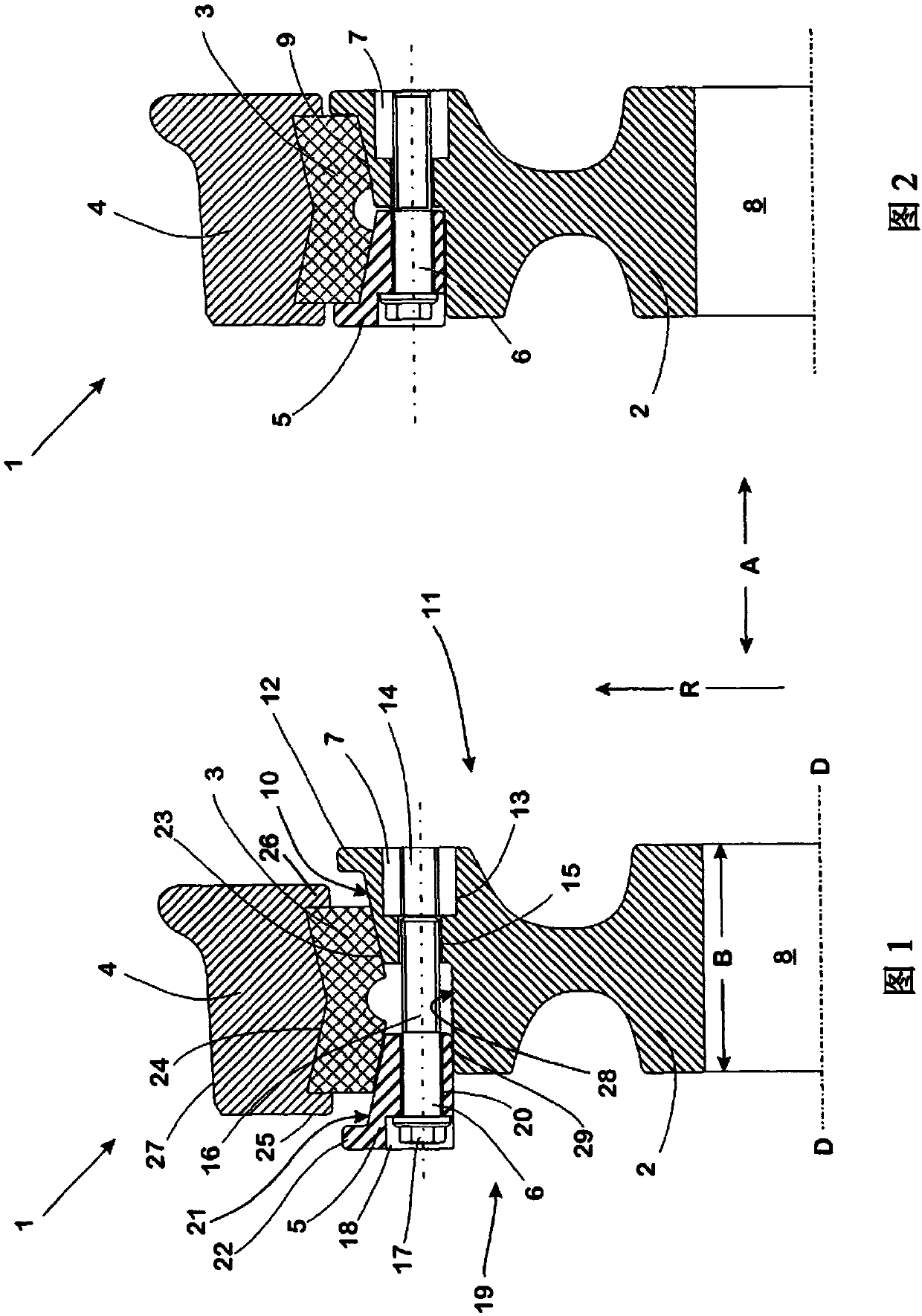

[0040] figure 1 and 2 The rail wheel 1 shown in includes a wheel body 2, an elastic body 3, a tire 4, a tightening ring 5, a plurality of fixing bolts 6 and a support member 7 used as a tightening device.

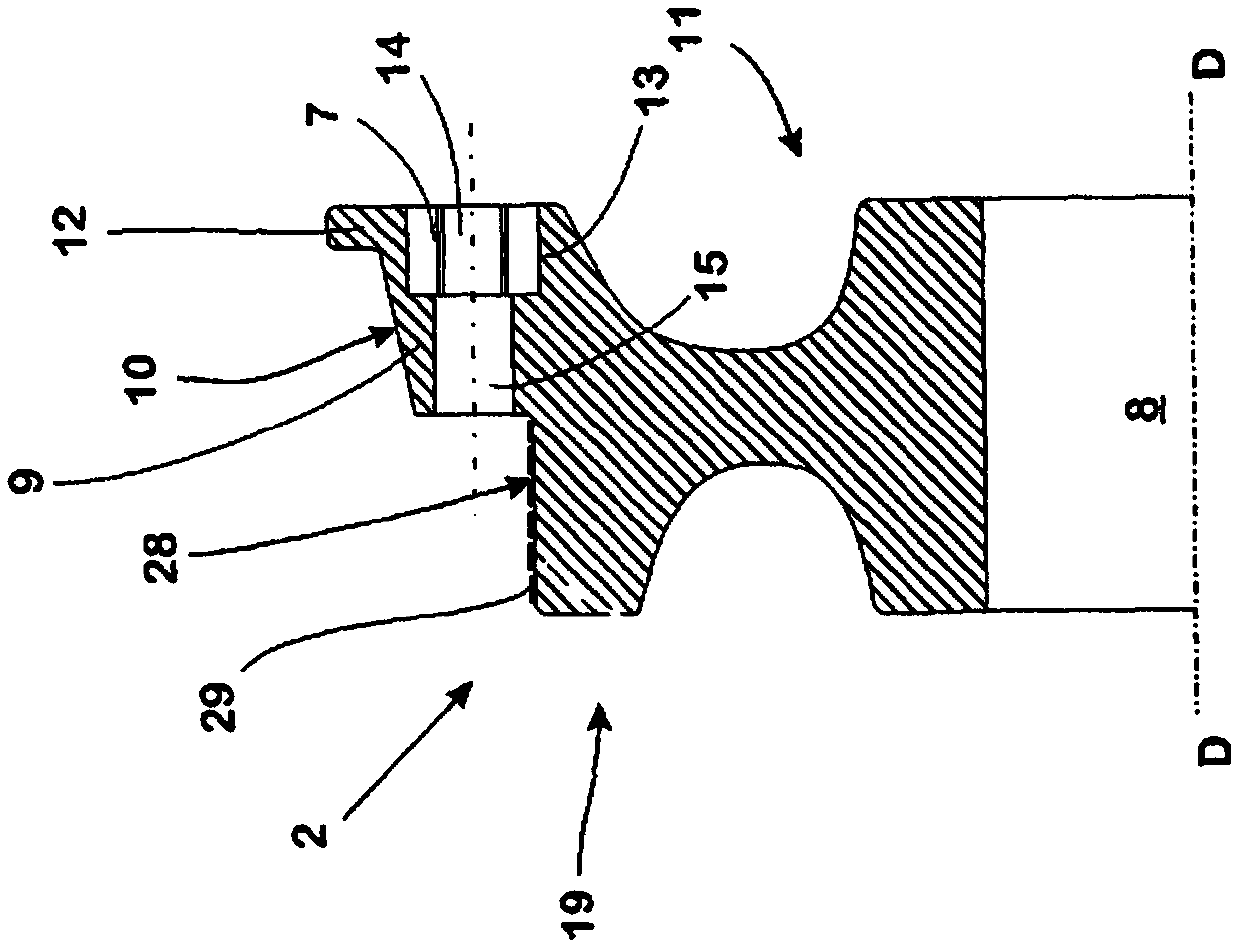

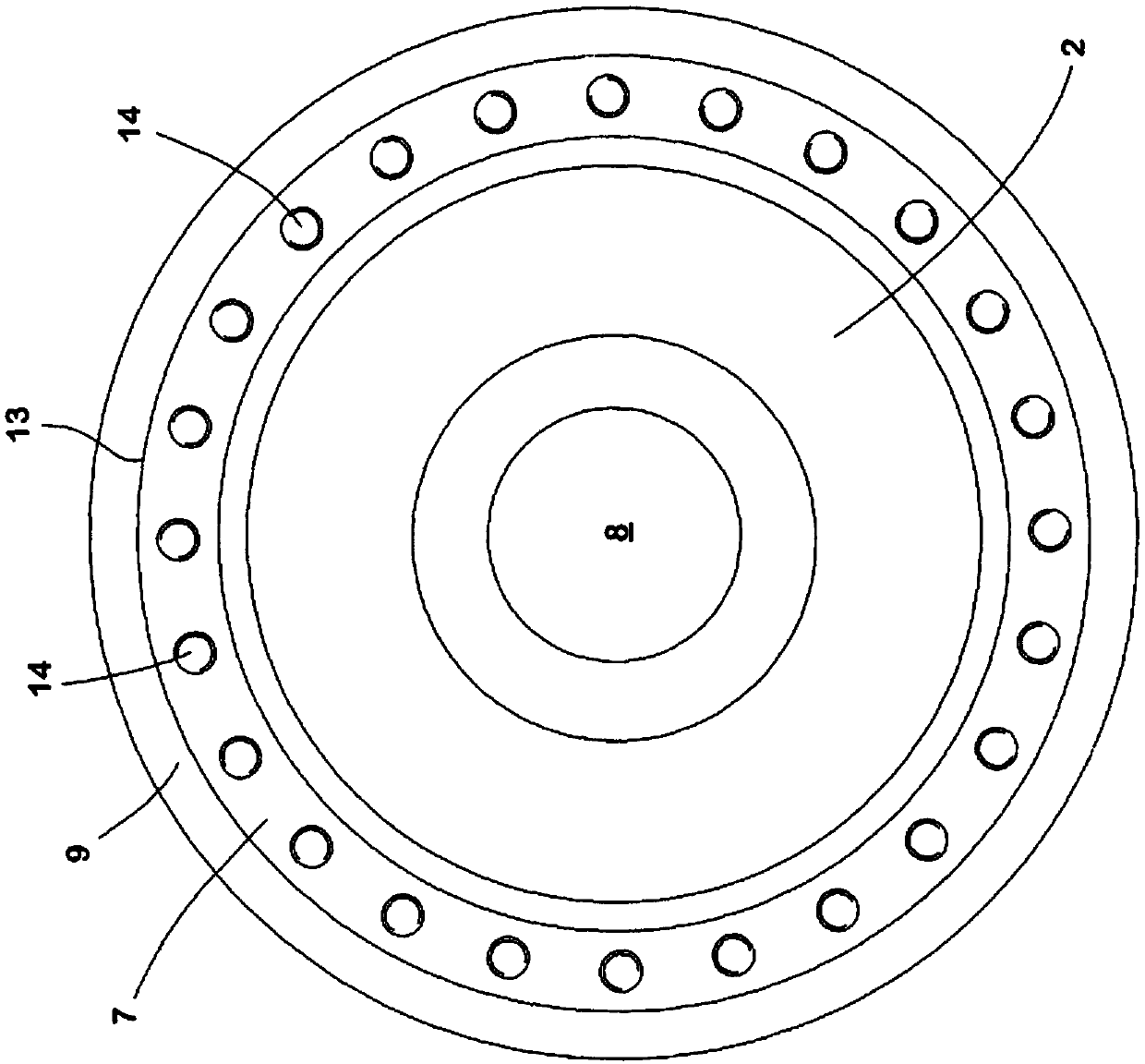

[0041] The wheel body 2 is forged in one piece in a known manner from a proven aluminum material. It has a central hub opening 8 through which the rotational axis of the rail wheel 1 extends. Around the circumference of the wheel body 2 there is a peripheral shoulder 9 which extends approximately over half the width B of the wheel body 2 and whose peripheral surface 10 is in the form of a conical ring in the direction of the center of the width of the wheel body 2 Shaped with a sloping descent.

[0042] At the axially outer edge of the peripheral shoulder 9 , which corresponds to the end face 11 of the wheel body 2 , the peripheral shoulder carries a surrounding beam 12 . A receptacle 13 formed in the manner of an annular groove around the axis of rotation D is formed s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com