Non-dusting poly (phenylene ether) particles

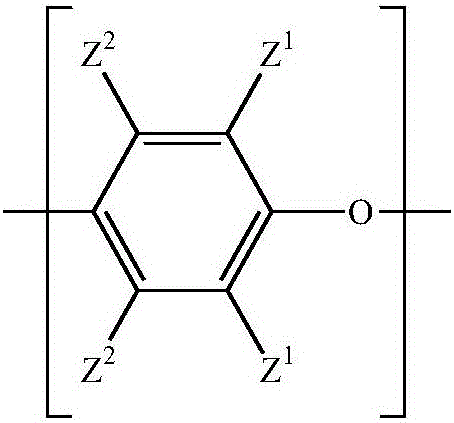

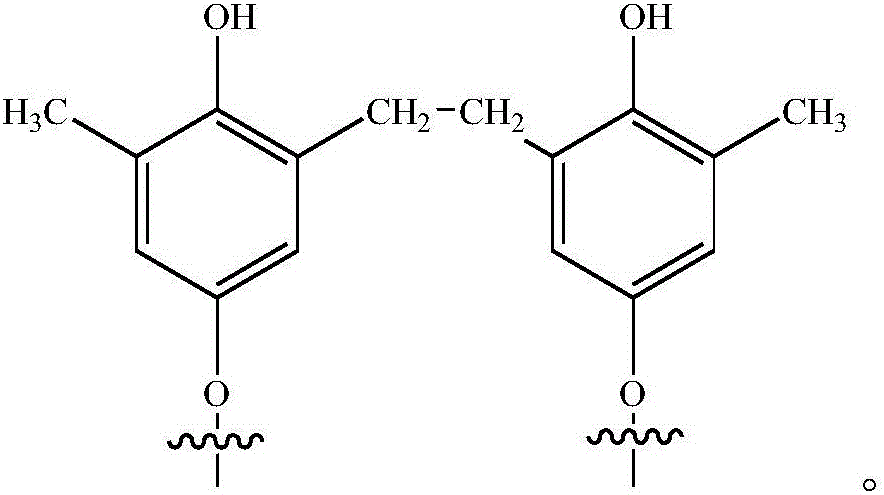

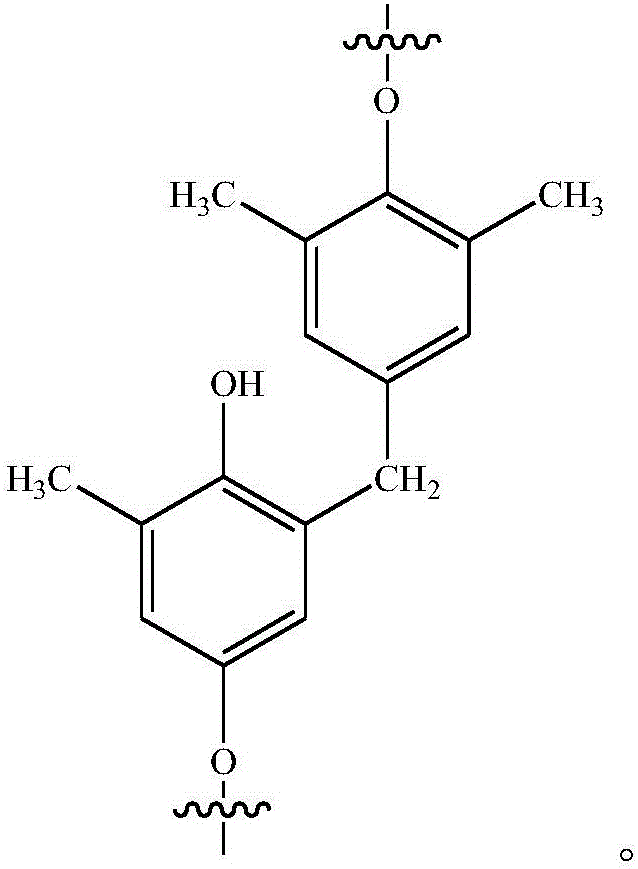

A phenylene ether and particle technology, which is applied in the field of dust-free poly(phenylene ether) particles and can solve problems such as affecting the physical properties of the composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0085] Embodiment 1: non-dusting poly(phenylene ether) particles comprising: 80 to 96 weight percent poly(phenylene ether) particles having an average particle size of 1 to 40 microns; and 4 to 20 weight percent a liquid reactive diluent; wherein all amounts are based on the combined weight of the poly(phenylene ether) particles and liquid reactive diluent; and wherein the non-dusting poly(phenylene ether) particles do not comprise all of the following: Poly(alkenyl aromatic) resins, rubber-modified poly(alkenyl aromatic) resins, and hydrogenated, partially hydrogenated, and non-hydrogenated block copolymers of alkenyl aromatic monomers and conjugated dienes.

Embodiment approach 2

[0086] Embodiment 2: The non-dusting poly(phenylene ether) particles of Embodiment 1, further comprising 0 to less than 0.1 parts of liquid polyethylene glycol, mineral oil, silicone liquid, and combined hydroxyl-terminated polybutylene per 100 parts poly(phenylene ether) particles.

Embodiment approach 3

[0087] Embodiment 3: The non-dusting poly(phenylene ether) particle of Embodiment 1 or 2, wherein the liquid reactive diluent is selected from a first polyol having at least two hydroxyl groups per molecule, a first ring An epoxy resin, a first ethylenically unsaturated monomer, a polyether-modified polysiloxane, and combinations thereof.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap