Novel skip adjusting device

A technology for adjusting devices and material carts, which is applied to stone processing tools, work accessories, manufacturing tools, etc., can solve problems affecting processing accuracy, poor fixing accuracy, and unfavorable production safety, so as to extend the service life, expand compatibility, and support reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

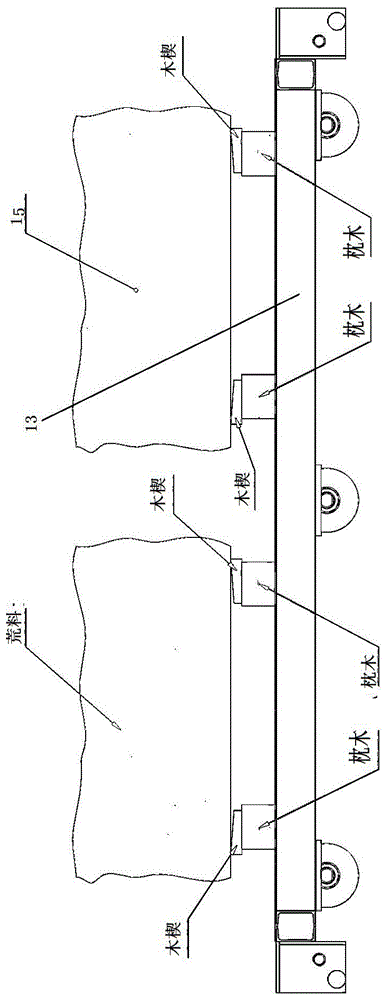

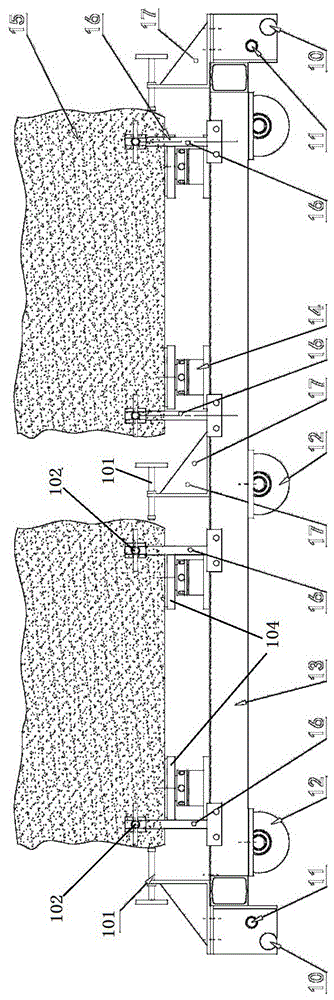

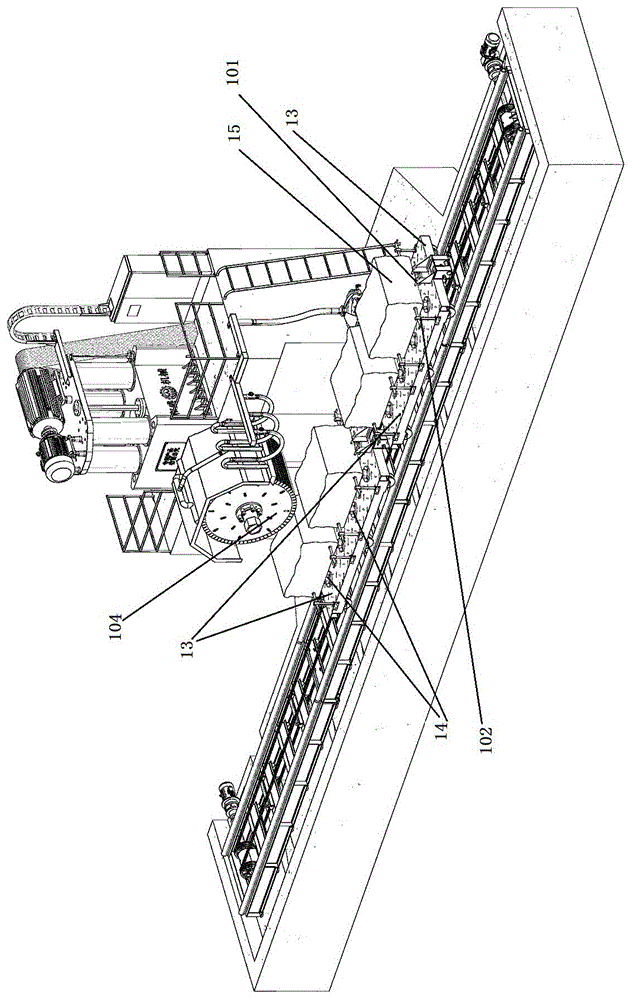

[0031] On the large-scale stone cutting machine, the feed truck 13 fixes the hook with the hook positioning pin 11 and the hook positioning pin 10 of the headstock, and the hook drives the feed truck 13 to run in a straight line on the track with the material wheel 12, and the operator hoistes the block 15 onto the feed truck On the adjustment base of the adjustment device, adjust the height of the block by adjusting the height of the support plate 104, and adjust the extension length of the push rod 101 and the push rod 102 on the side of the car to press against the block 15. Adjust the side posture of the block 15 and clamp the block 15 by adjusting the push rod 101 and the push rod 102 on the side of the car. After the block is fixed, the material cart 13 carries the block and advances to the cutting tool 103. The block material 15 is cut while the feed truck is advancing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com