Vehicle pneumatic tire

A technology for pneumatic tires and vehicles, which is applied to vehicle parts, tire parts, tire treads/tread patterns, etc. It can solve problems such as poor water skid characteristics, unevenness, and wear, and achieve uniform wear and optimized stiffness distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

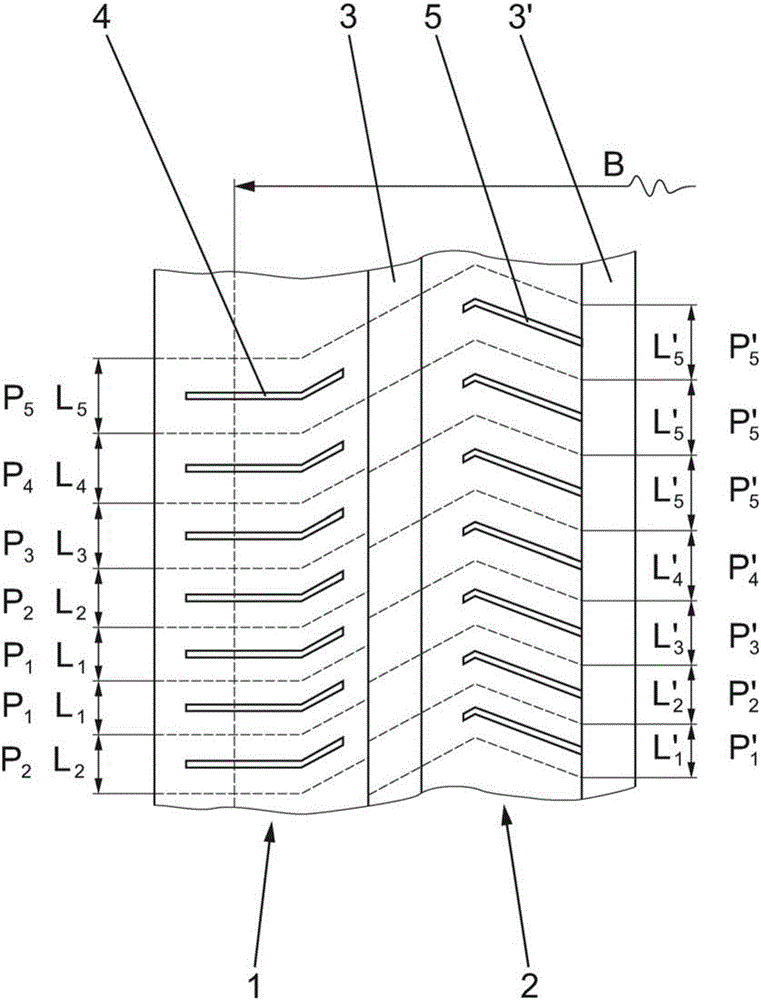

[0016] exist figure 1 In , one tread of a pneumatic tire for vehicles shows one rib 1 and another rib 2 in a radial configuration for cars, trucks and similar vehicles, the other rib being passed through a wide , the circumferential groove 3 surrounding in the circumferential direction is separated from the tread rib 1 . Instead of the tread ribs, it is also possible to provide circumferential rows of tread blocks in the circumferential direction. In the illustrated embodiment, a further circumferential sipe 3' running around in the circumferential direction extends along the rib 2 on the inside of the tread, which is adjoined by a not shown sipe. Both the tread rib 1 and the tread rib 2 are of a block structure, the tread rib 1 is constructed by the transverse groove 4 , and the tread rib 2 is constructed by the transverse groove 5 . exist figure 1 In the embodiment schematically shown in , the transverse grooves 4 extend in such a way that they are at a distance inside th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com