A fully-automatic tea leaf vacuum packaging machine

A vacuum packaging machine, fully automatic technology, applied in the field of packaging and processing, can solve problems such as poor sealing of tea packaging, achieve good sealing effect, avoid slipping out, and ensure the effect of sealing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

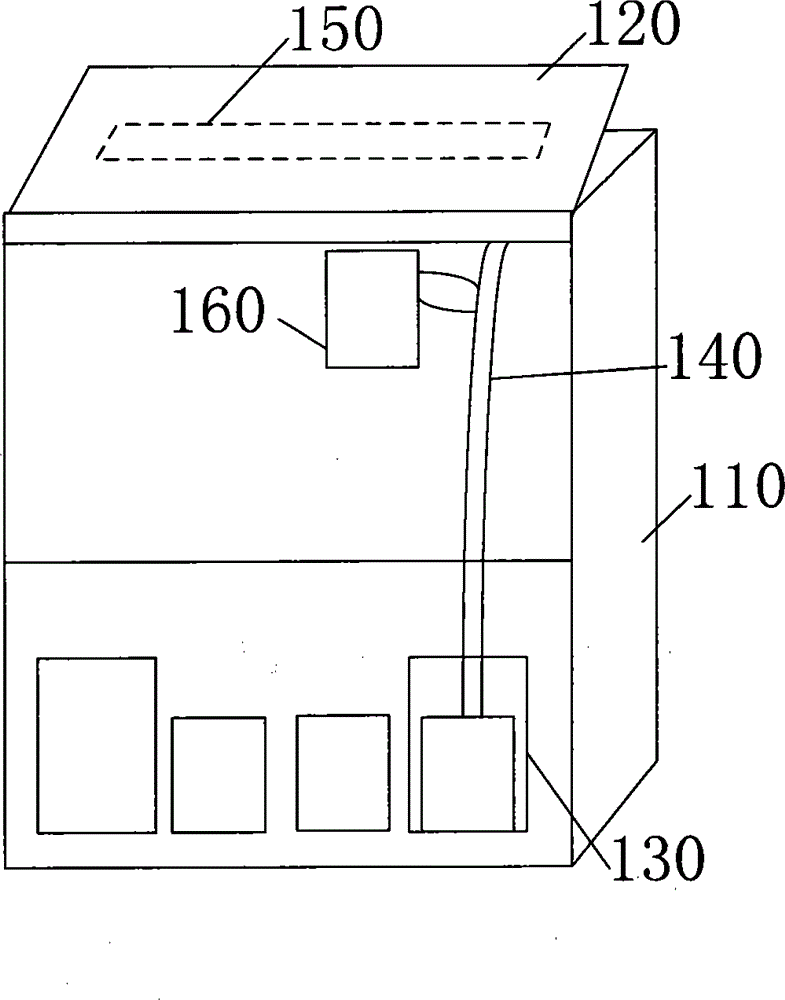

[0010] Such as figure 1 As shown, a fully automatic tea vacuum packaging machine is mainly composed of a frame 110, a vacuum pump 130, a vacuum chamber, a sealing strip, a plexiglass cover 120, an air bag and an electromagnetic valve. There is a sealing pad 150 corresponding to the sealing strip, the sealing pad 150 has a groove-like structure, the air bag is connected to the vacuum pump 130 through the air inlet pipe 140, and the two ends of the sealing pad 150 are closed. The sealing pad 150 can effectively avoid the phenomenon that the product packaging slips out when sealing the product packaging, so that the sealing effect is better and the sealing quality is guaranteed.

[0011] An oil container 160 is installed on the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com