A drain valve inner core tube clamping device

A technology of inner core pipe and drain valve, applied in water supply devices, flushing equipment with water tanks, buildings, etc., can solve the problems of wasting water resources and inability to achieve accurate drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. The pivot joint referred to herein means that one component can swing relative to another component.

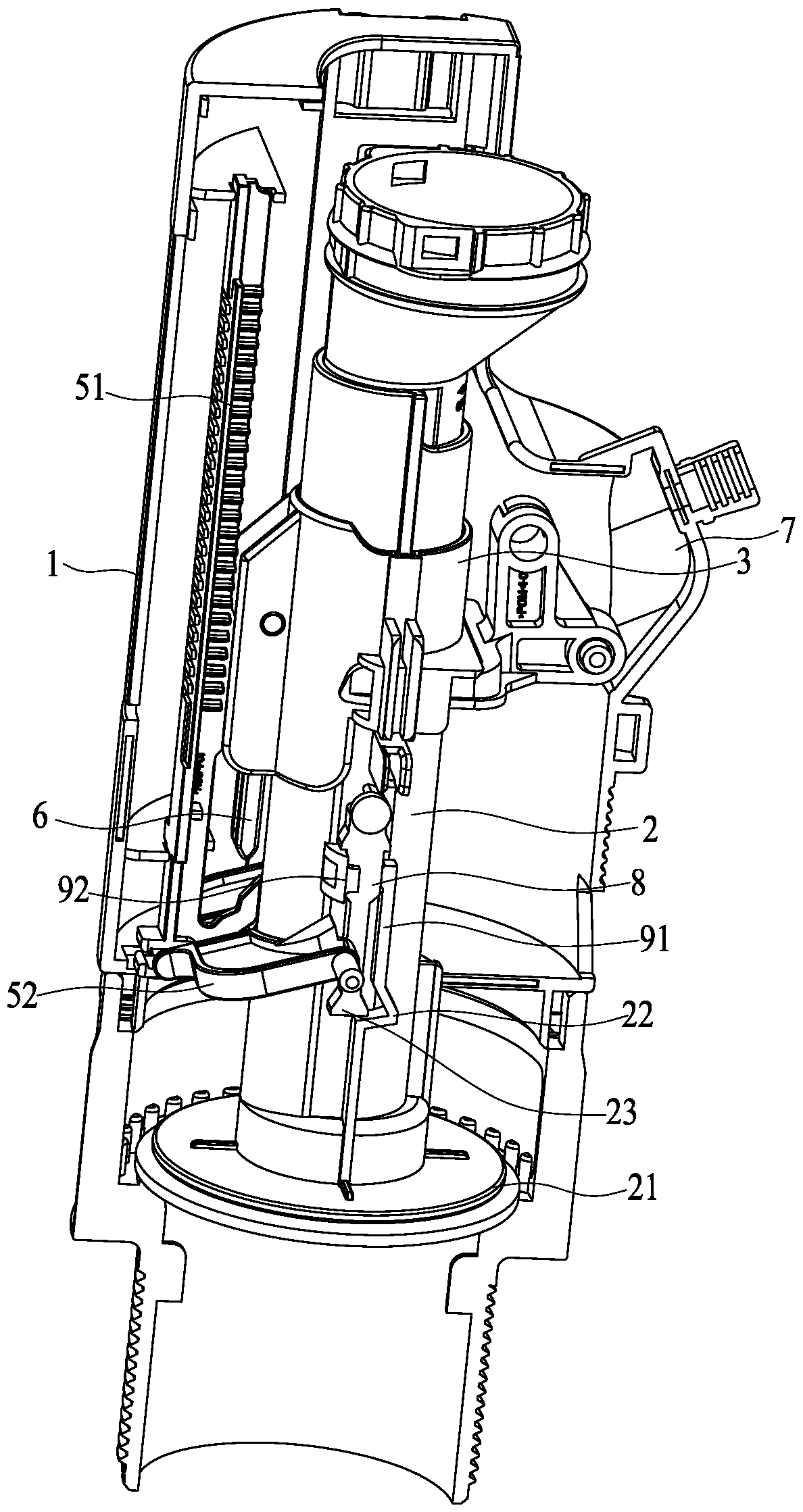

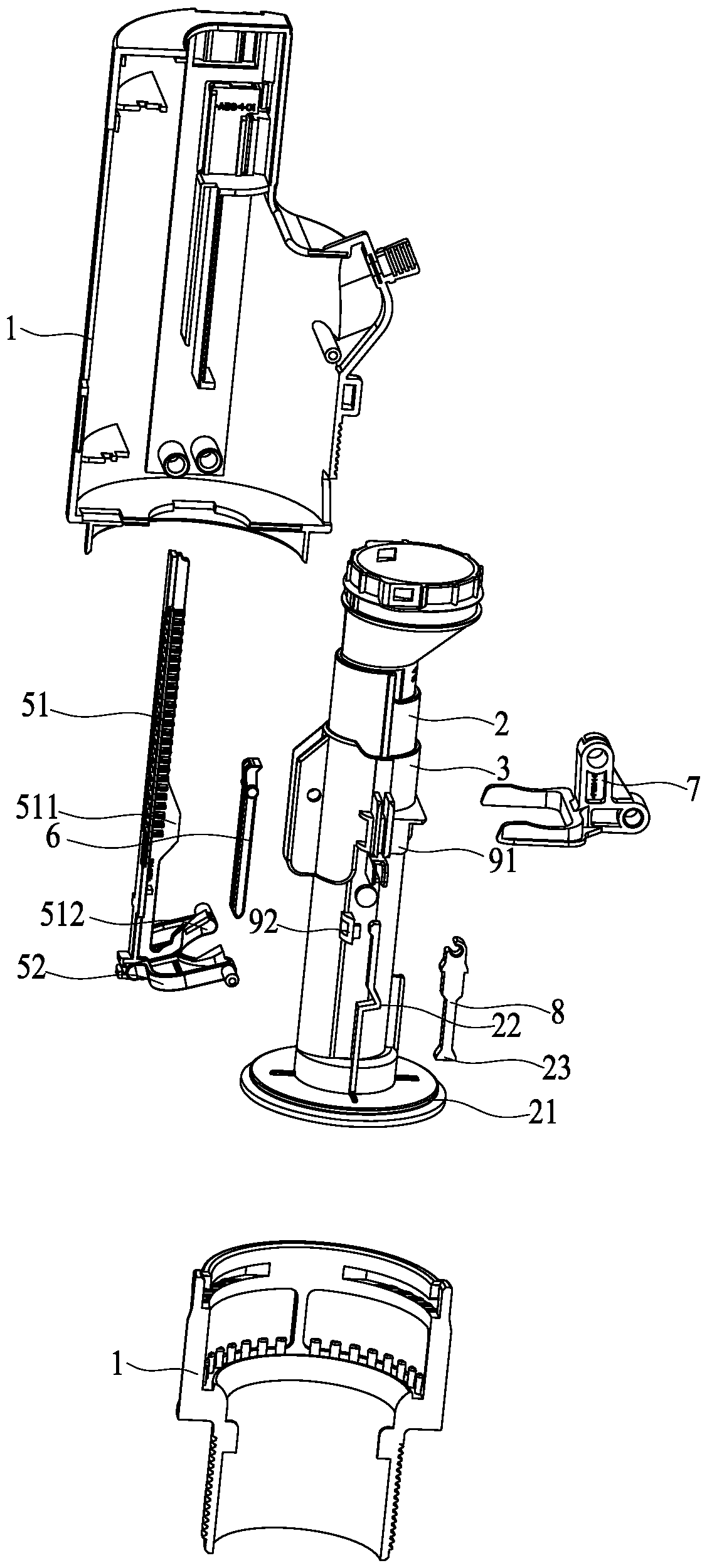

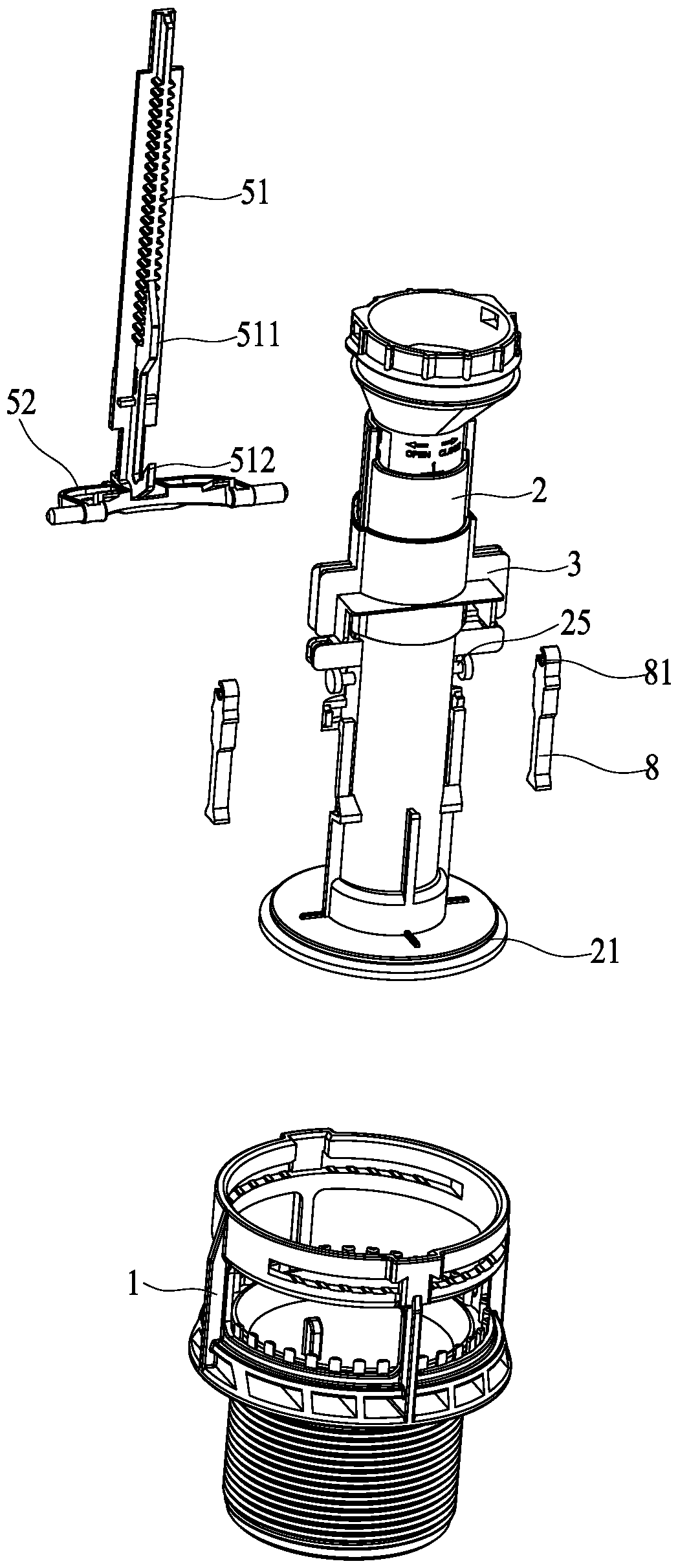

[0080] refer to Figure 1 to Figure 29 As shown, a drainage valve inner core tube clamping device disclosed by the present invention includes a main body 1, an inner core tube 2, an upper lifter 3, a half row of floating buckets 41, a full row of floating buckets 42, a half row of adjusting rods 51, Half row of brackets 52 and locking bar mechanism.

[0081] Such as Figure 1 to Figure 13 As shown, the lifter 3 is slidably connected to the upper part of the inner core tube 2, and the lifter 3 is driven up by the button mechanism 7. In this embodiment, the lifting part 3 is a sleeve, which is movably sleeved on the upper part of the inner core tube 2 , and the sleeve is driven by the button mechanism 7 to rise in the body 1 . Certainly, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com