Scaffold structure

A construction frame and crossbar technology, which is applied in the direction of house structure support, house structure support, building structure, etc., can solve the problems of high production cost, affecting the convenience of the rod, and troublesome operation, and achieves low cost, rapid assembly, The effect of easy disassembly and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

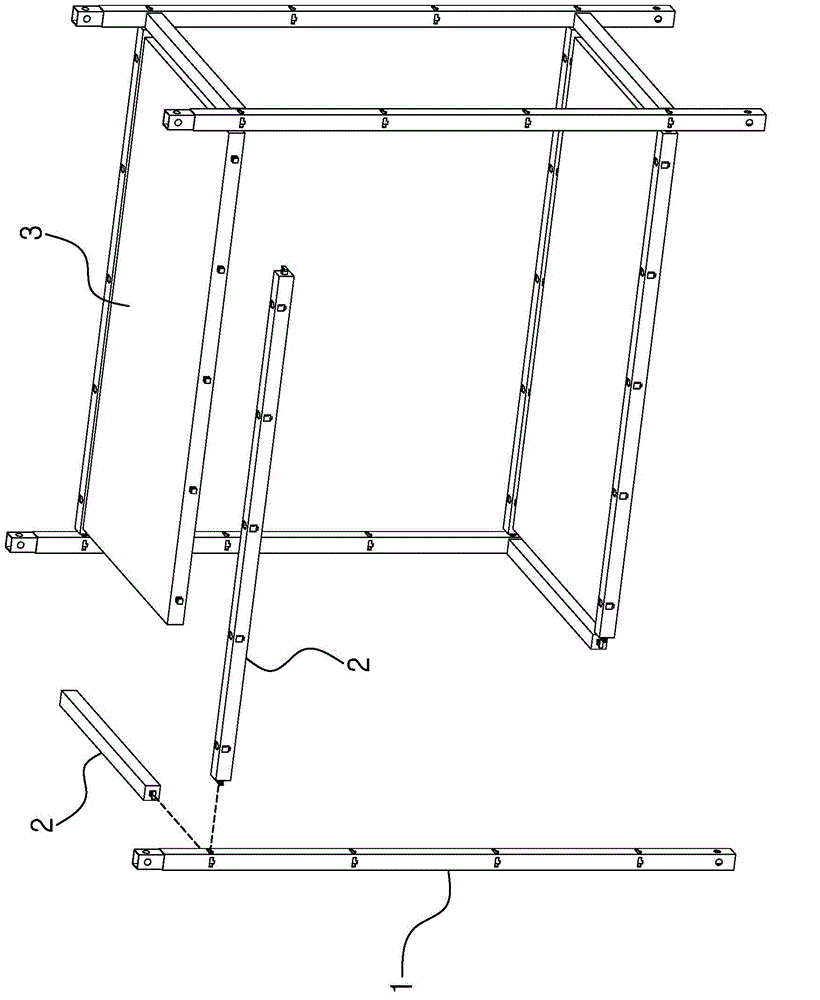

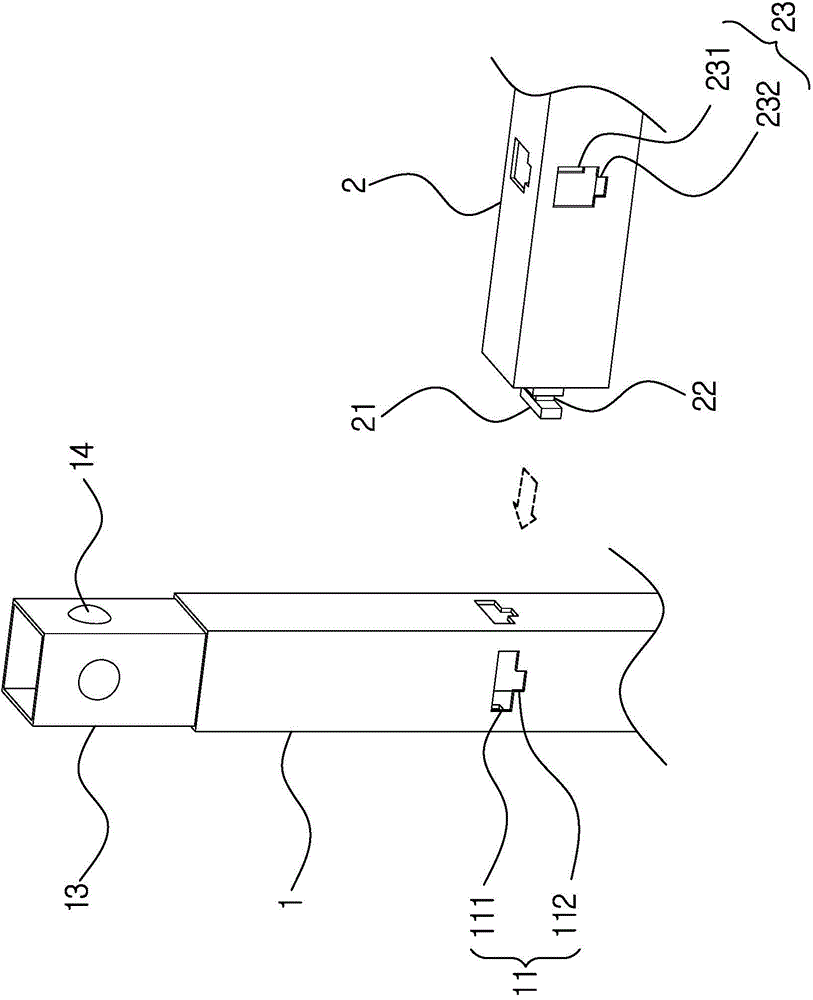

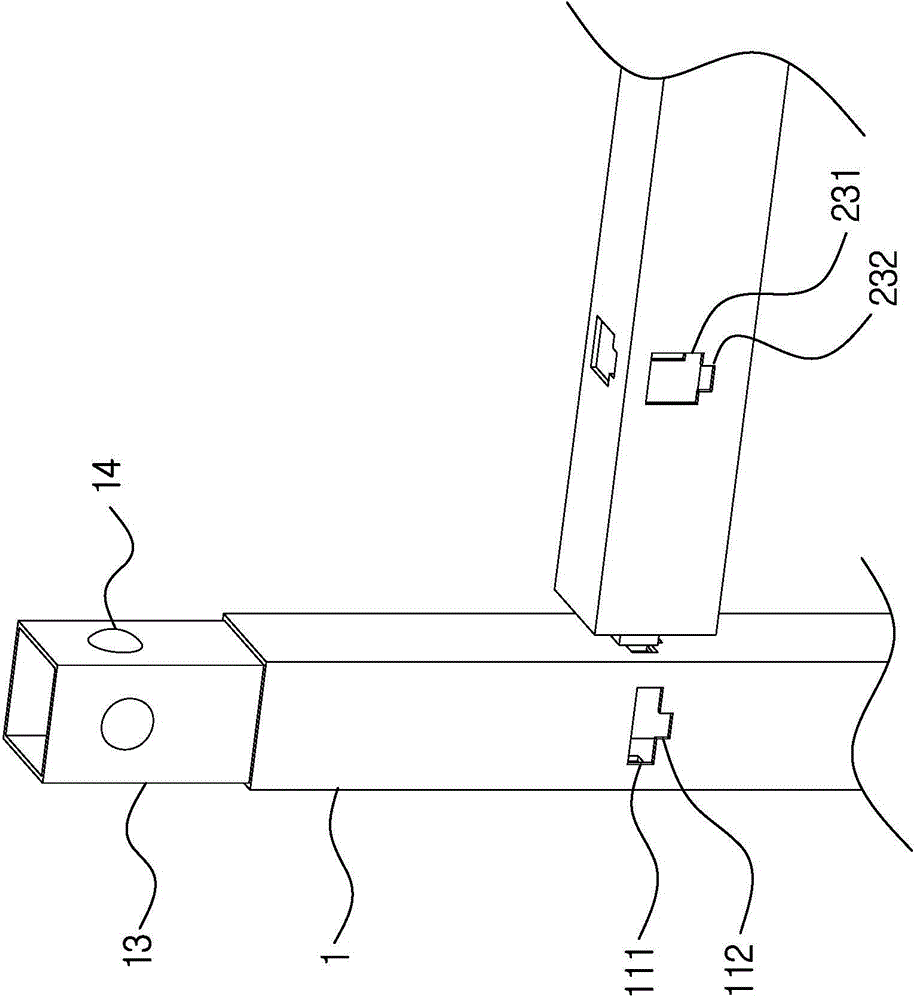

[0022] The invention relates to a construction frame structure, which is a construction platform for workers to stand on elevated, and the construction frame has the characteristics of quick assembly and disassembly, please refer to figure 1 and Figure 10 As shown, the "construction frame structure" of the present invention includes a plurality of hollow vertical rods 1, a plurality of hollow cross rods 2 and at least one platform 3 (the vertical rods 1 and the cross rods 2 of the present invention are illustrated in the embodiment of a rectangular rod body, the actual Round rods, triangular rods or polygonal rods can also be used in applications);

[0023] At least one groove 11 is formed on the side of the pole 1, and the groove 11 is formed by connecting two grooves, one of which is located in the upper wide groove section 111, and the other groove is located in the lower narrow groove section. 112, the two ends of the cross bar 2 are respectively formed with a projection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com