Gas valve with improved sealing characteristics

A technology for air valves and seals, applied in the field of air valves, can solve problems such as the inability to calibrate the size deviation of elastomer seals, and achieve the effect of improving the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

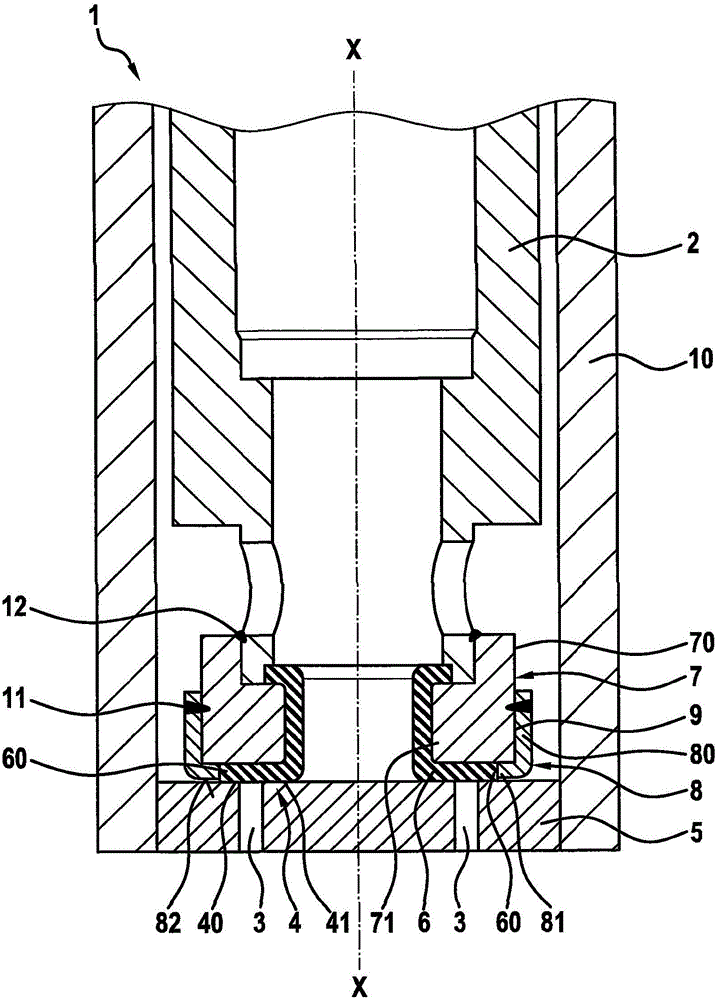

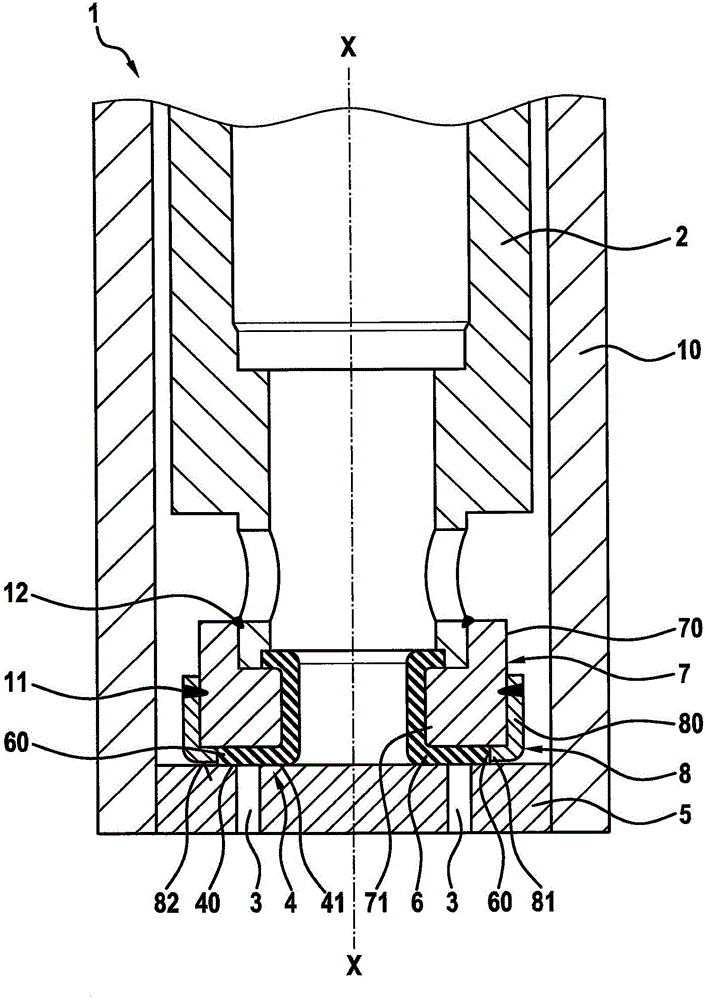

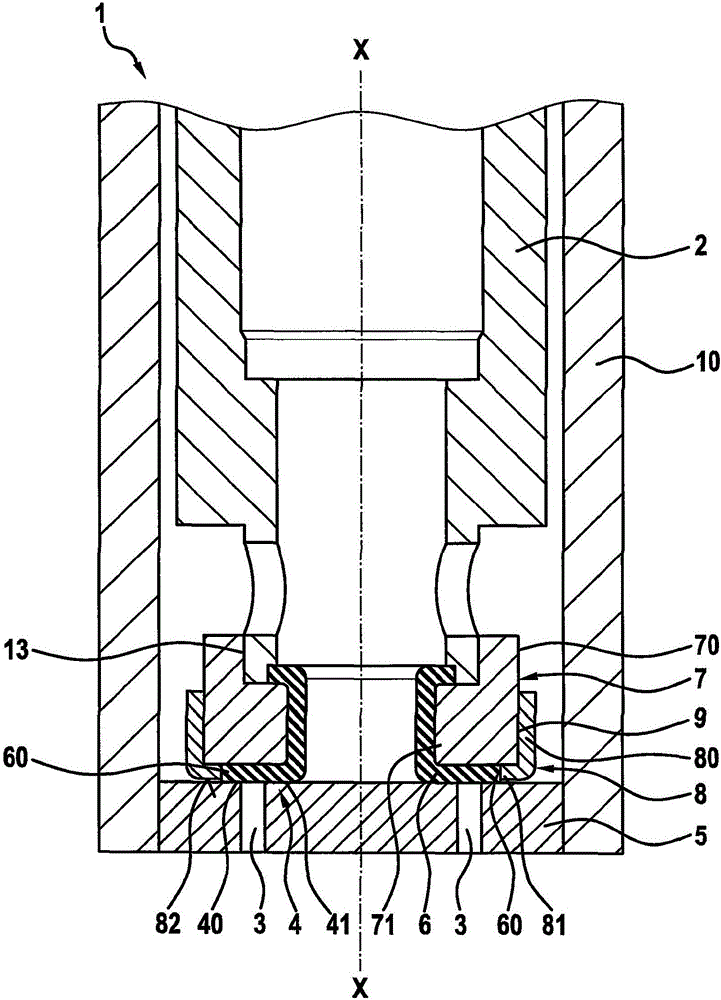

[0021] Refer to the following figure 1 The valve 1 according to the first embodiment of the present invention will be described in detail.

[0022] as by figure 1 It can be clearly seen that the valve 1 comprises a movable valve closing element 2 , which in this embodiment is a magnetic armature. The valve closing element 2 is designed as a hollow cylinder, so that gaseous fuel can be guided not only inside the valve closing element 2 but also outside.

[0023] The valve closing element 2 is arranged in a valve body 10 which is closed by a sealing gasket 5 providing a valve seat. The valve body 10 is a hollow cylindrical component and seals the sealing gasket 5 at its free end. A plurality of kidney-shaped through-openings 3 are provided in the sealing washer 5 , which are released and closed by means of the valve closing element 2 . figure 1 Shows the closed state of the valve.

[0024] In order to achieve reliable sealing of gaseous media, an elastomer seal 6 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com