Aluminum profile connection structure and corner code for connection structure

A technology for connecting structures and aluminum profiles, applied in the direction of connecting components, rods, mechanical equipment, etc., can solve problems such as less degrees of freedom, loose screw connections, breakage, etc., and achieve fast and convenient installation, reasonable and stable positioning, and fast positioning connections Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Please refer to Figure 1 to Figure 6 , Embodiment 1 of the present invention is:

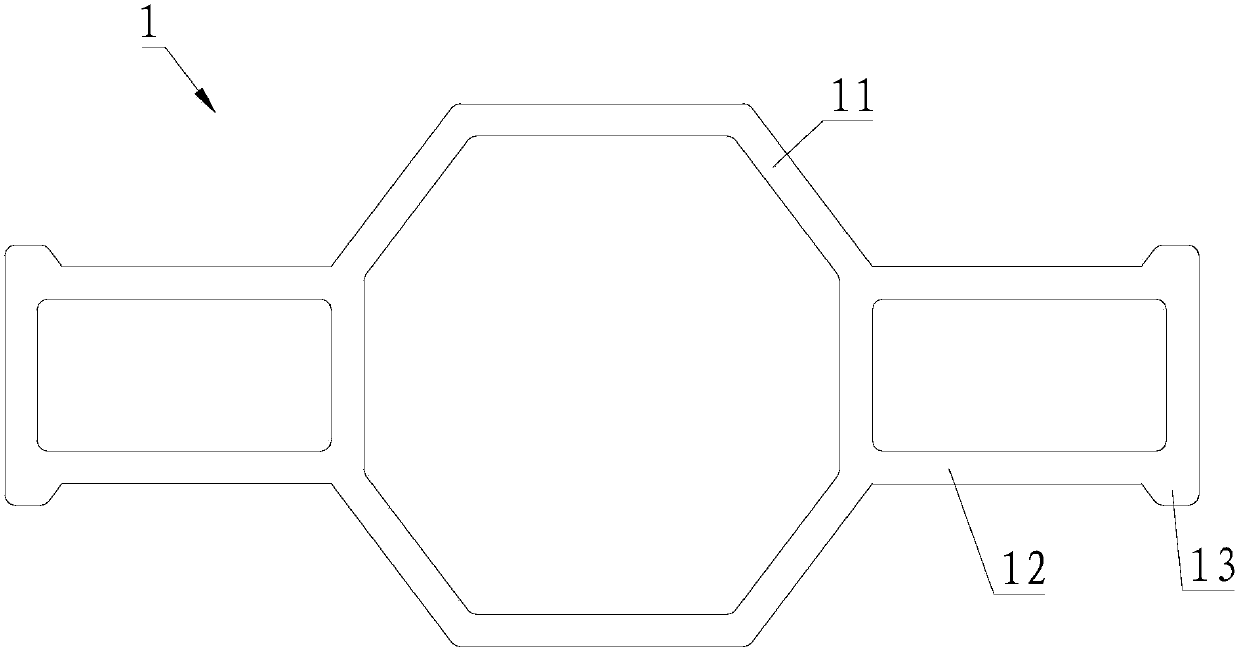

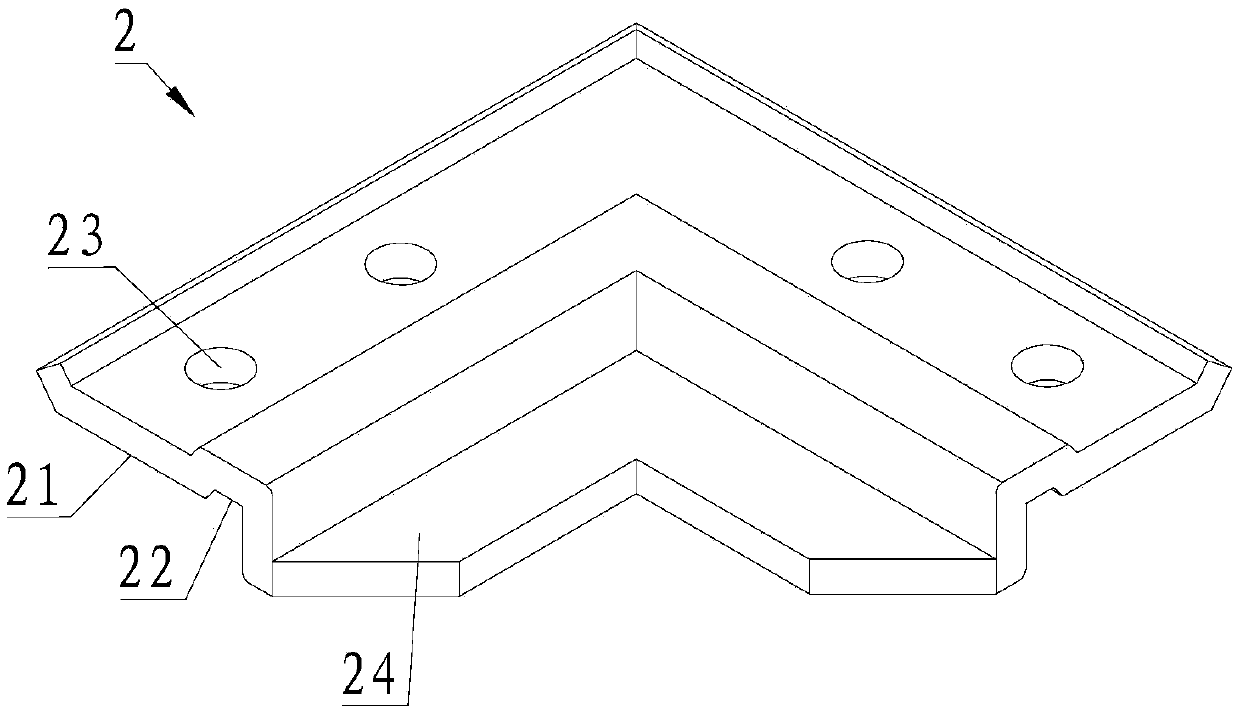

[0029] A connection structure between an aluminum profile 1 and a corner bracket, comprising two aluminum profiles 1 and corner brackets arranged perpendicularly to each other, the corner bracket includes a pair of symmetrically arranged L-shaped corner brackets 2, and the aluminum profile 1 includes an aluminum profile The main body 11, the outer surface of the aluminum profile main body 11 is provided with a door-shaped protrusion 12, and the inner surface of the angle code piece 2 is provided with a first groove 21 with an L-shaped cross section. The angle code piece 2 The first groove 21 of the first groove 21 is connected with the gate-shaped protrusions 12 of the two mutually perpendicular aluminum profiles 1 at the same time, and the two corner code pieces 2 are clamped and arranged opposite to each other; the corners of the gate-shaped protrusions 12 A trapezoidal protrusion 13 ...

Embodiment 2

[0040] Please refer to Figure 2 to Figure 6 , the second embodiment of the present invention is:

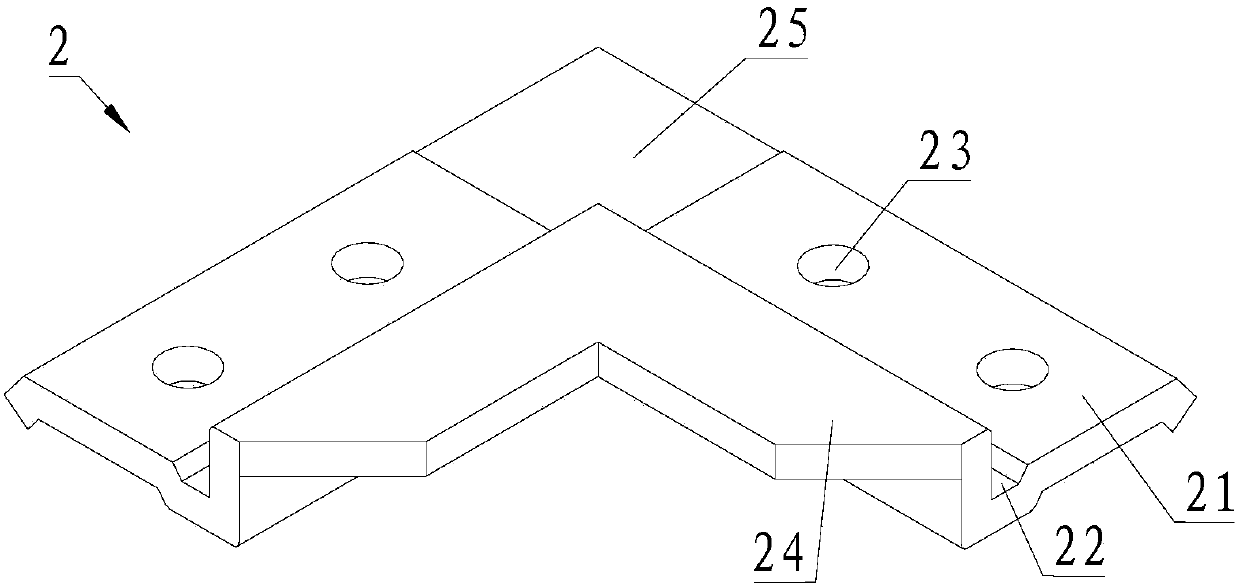

[0041] An angle code for a connection structure, including a pair of symmetrically arranged L-shaped angle code pieces 2, a first groove 21 with an L-shaped cross-section is provided on the inner side of the angle code piece 2, and the angle code piece 2 Through the first groove 21 and the two external aluminum profiles 1 that are perpendicular to each other are attached and connected, a pair of corner codes 2 are clamped to each other, and a pair of first grooves 21 of the corner code 2 The second through hole 23 is provided on the opposite surface, and the second through hole 23 is adapted to the external screw 3, and the second through hole 23 is provided on the opposite surface of the first groove 21 of the two angle code pieces 2. Groove 22, the cross-sectional shape of the second groove 22 is trapezoidal, the second groove 22 is connected with the peripheral aluminum profil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com