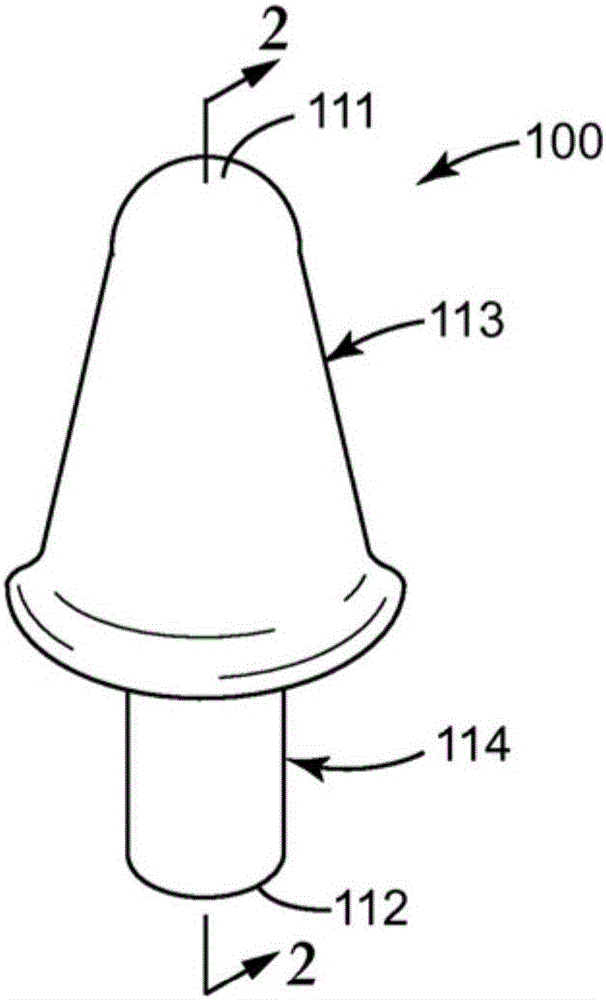

Molded foam push-to-fit earplug, method and devices

A technology of earplugs, composition, applied in the field of hearing protection devices, which can solve the problems of difficult manufacturing, expensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

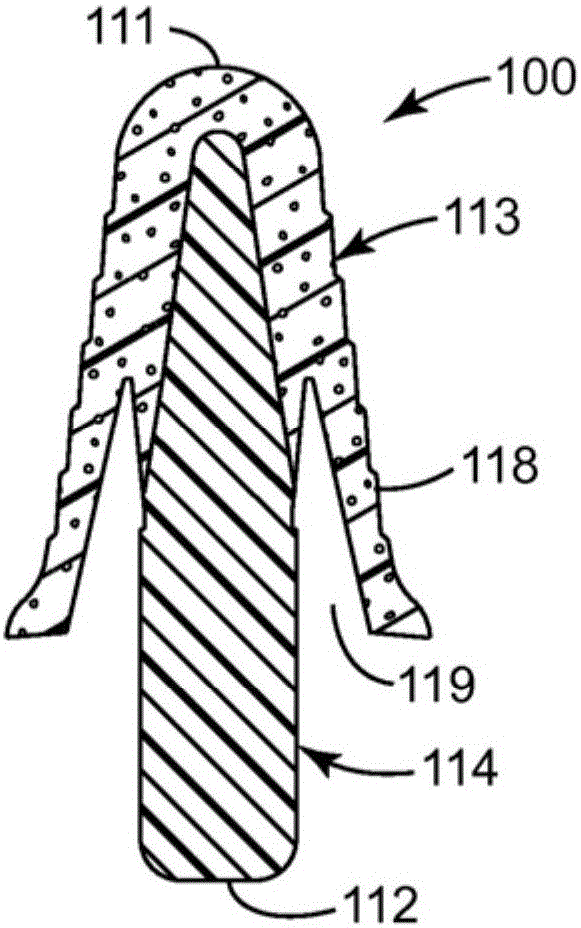

[0053] The earplugs of embodiments 1 to 3 are used in relation to Figure 4A and 4B The molds prepared during the secondary injection molding process are shown and described. Prepare and dynamically mix using a dynamic high shear mixer at an average rate between 10 revolutions per gram of pumped material and 30 revolutions per gram of pumped material 73.6 parts of Encor 154S acrylic latex material available from Arkema Ltd.; 19.0 parts of water-based pigments available from DAYGLO Color Corporation (DayGlo Color Corporation); and 4.0 parts surfactant cell regulator.

[0054] Molds were prepared by applying H-15-1N mold release agent available from Releasagen Manufacturing Inc and heating the mold to approximately 45°C. The mixed material is dispensed into the sound absorbing portion cavity and the mold top is placed on the mold to provide a vent cavity in the form of the sound absorbing portion. After partial curing, the mold top was removed and replaced with a mold insert...

Embodiment 4-6

[0056] The earplugs of embodiments 4 to 6 are used in relation to Figure 4A and 4B The molds prepared during the secondary injection molding process are shown and described. A dynamic high shear mixer was used to dynamically mix a mixture comprising 39 parts of Mondur PF II available from Bayer at an average rate between 10 revolutions per gram of pumped material and 30 revolutions per gram of pumped material. Isocyanate prepolymer; 50 parts of a blend of polyols comprising ARCOL PPG 425, ARCOL LHT 240 and MULTRANOL 9187 available from Bayer MaterialScience; Materials) NIAX Catalyst A-1, and a blend of BICAT V and BICAT Z available from Shepard Chemical Company, and 3 parts of powder pigment from DAYGLO Color Company; and 7 parts cellular surfactants.

[0057] The mold was prepared by applying a release coating H7228 mold available from Huron Technologies Incorporated and heating the mold to approximately 45°C. The mixed material is dispensed into the rod cavity and the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Modulus | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com