Cross joint type cathode feeding and annular liquid supplying mode blade full profile electrolysis system and method

An electrolysis system and cathode technology, applied in the direction of processing working medium supply, etc., can solve the problems of inability to achieve stable inlet and exhaust edges, precision machining, etc., to improve machining accuracy and repeatability, improve flow field uniformity, promote The effect of uniform erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

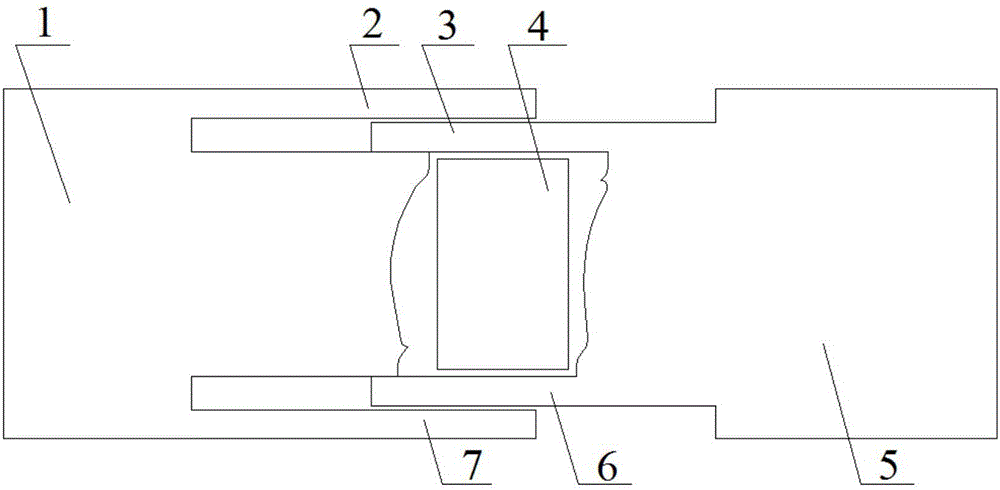

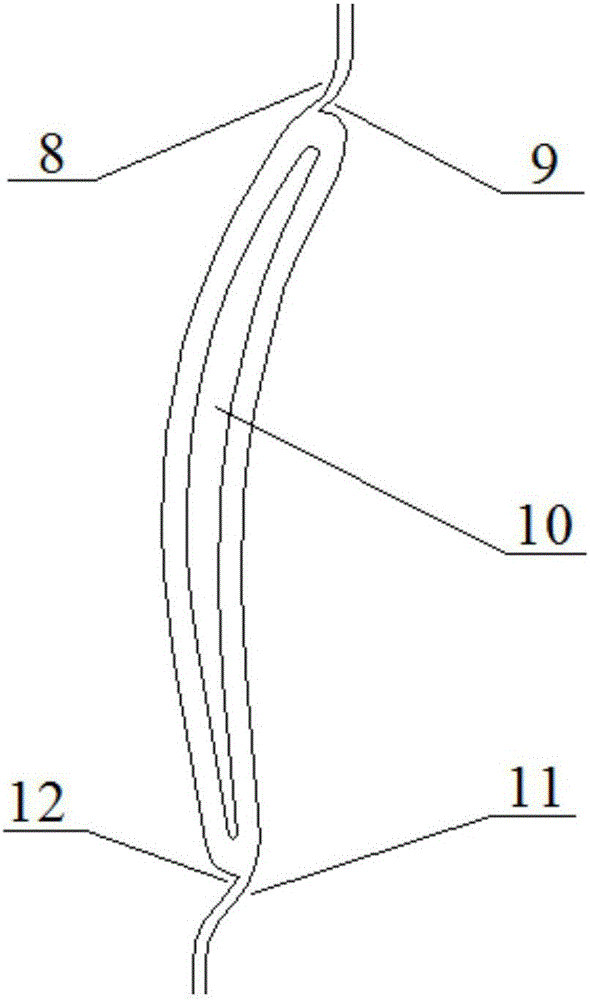

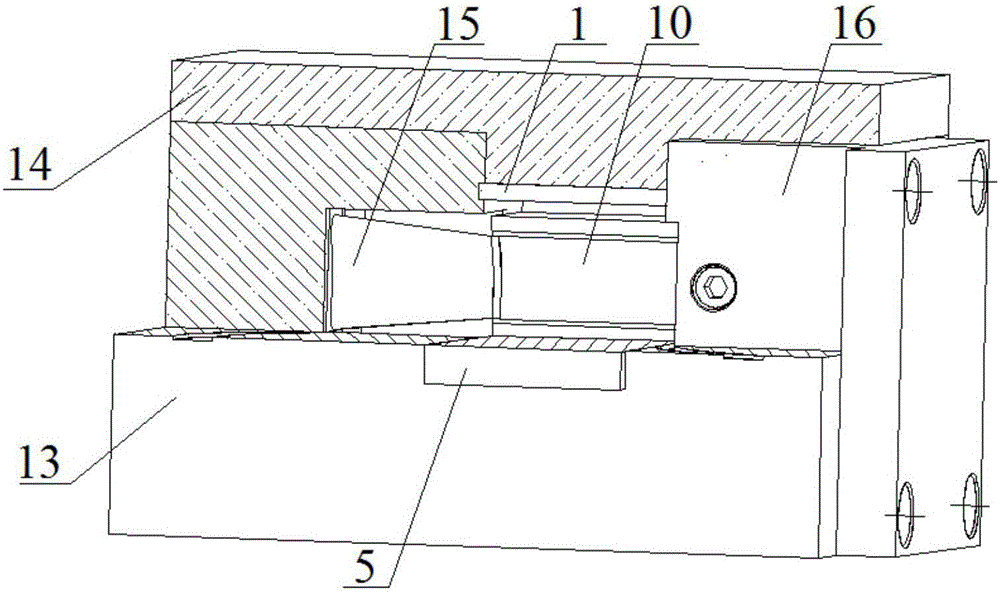

[0017] Such as Figure 4 As shown, the circulation fixture base 13 is made of insulating materials such as epoxy resin, and has a built-in liquid inlet channel 18, a circulation channel 19, a feed processing channel 20, a liquid outlet channel 21, a connecting channel A17 and a connecting channel B22; the liquid inlet channel 18 and The outlet channel 21 is used to connect the external electrolyte circulation system to ensure the dynamic circulation of the electrolyte during processing; the connection block 23 of the circulation auxiliary block 15 is placed in the connection channel A17, and is fixed inside the circulation fixture base 13, and the circulation auxiliary block The circulation block 25 of 15 is placed in the circulation channel 19 to realize the full profile liquid supply of the blade 10; the positioning part 30 of the workpiece 4 is loaded into the workpiece positioning device 16, and the workpiece positioning device 16 is installed on the connecting channel B, a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap