Ball cutter compensation method and device applied to stone mill curved surface machining, terminal and computer readable storage medium

A technology of curved surface processing and compensation method, applied in computer control, general control system, instrument, etc., can solve the problems of expensive ball cutter, irreversible positioning deviation, discontinuous surface to be processed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

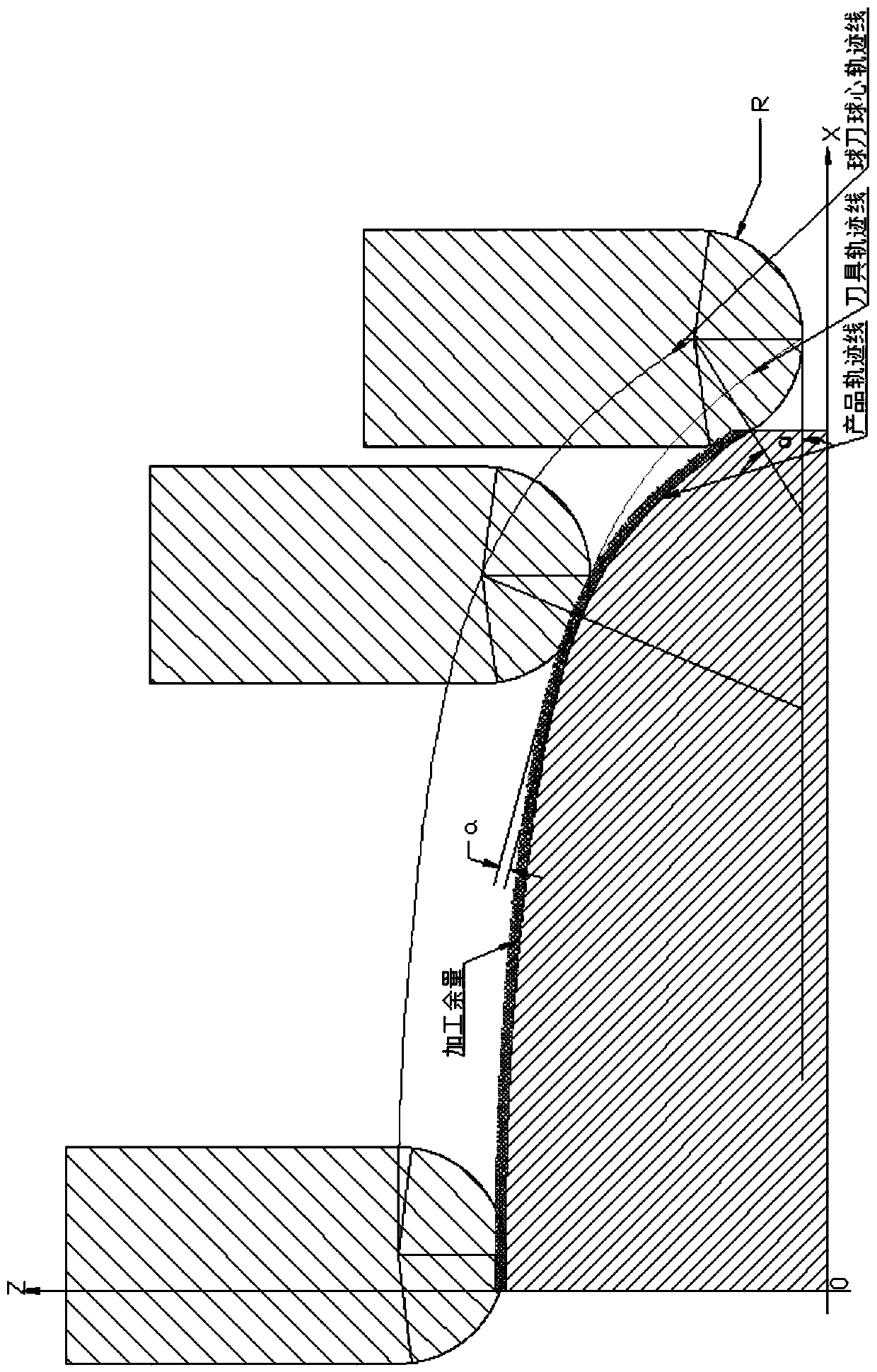

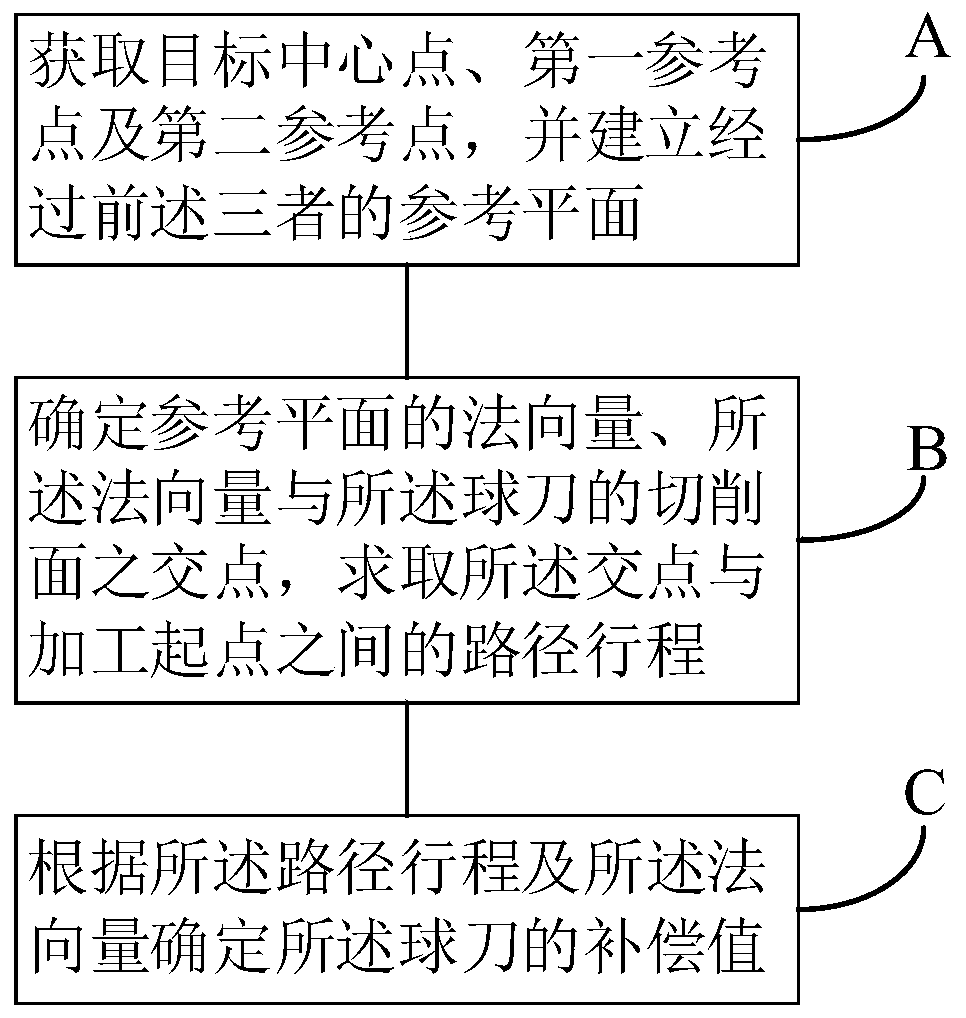

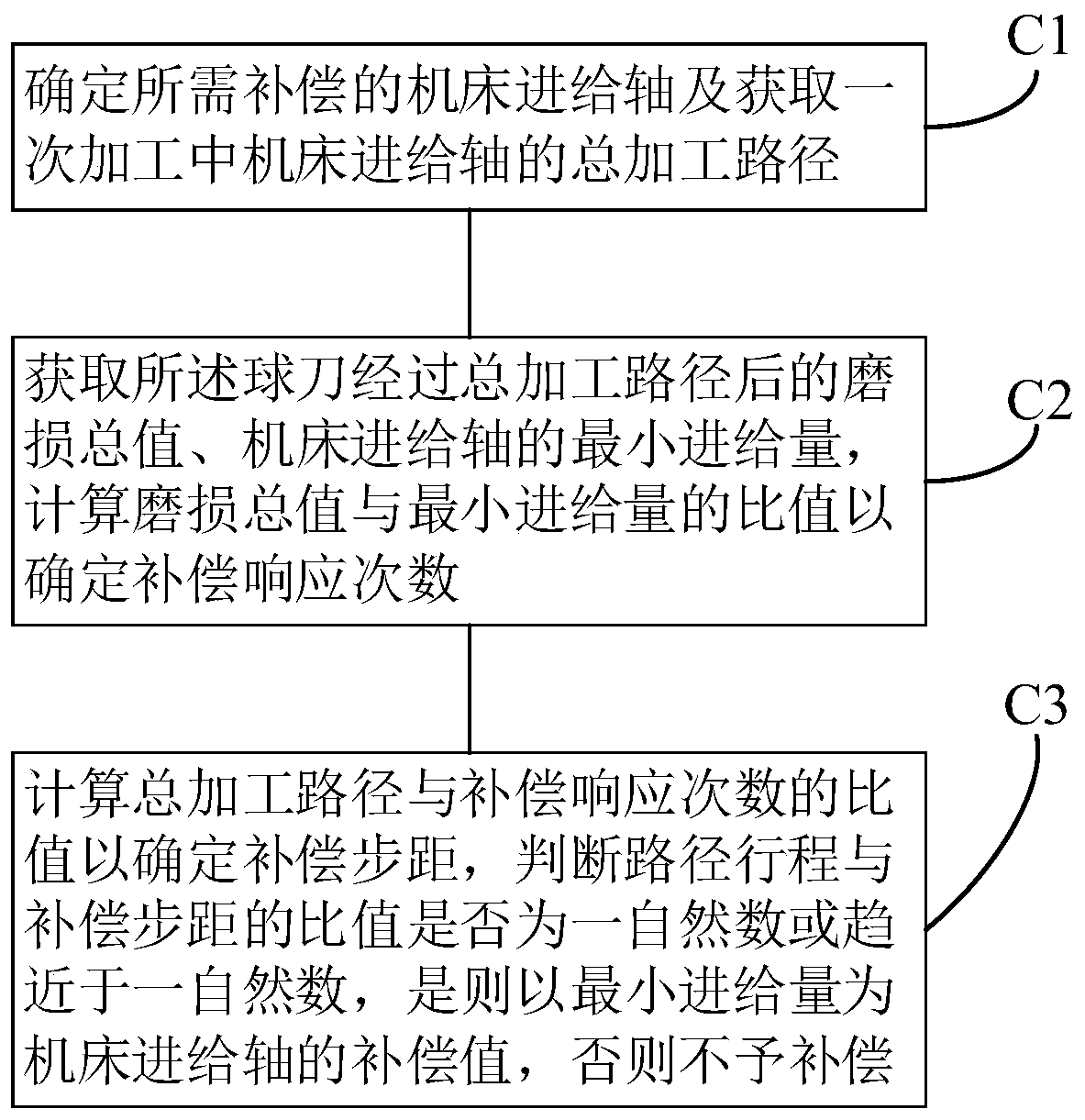

[0054] Please refer to Figure 1~2 , the present embodiment provides a ball cutter compensation method applied to stone grinding curved surface processing, the method includes the following steps:

[0055] Step A: Obtain the target center point, the first reference point and the second reference point, and establish a reference plane passing through the above three. Wherein, the target center point is the center position of the ball cutter when it passes through the processing point to be compensated, and the first reference point and the second reference point are the centers of the ball cutter closest to the target center point on the adjacent processing path position, the adjacent processing path remains adjacent to the processing path where the target center point is located. The so-called center position of the ball knife refers to the position of the ball center of the spherical blade of the ball knife.

[0056] When machining the curved surface of the graphite materia...

Embodiment 2

[0076] see Figure 5 , this embodiment provides a ball cutter compensation device applied to stone grinding curved surface processing, the device includes:

[0077] The plane establishment module 110 is used to obtain the target center point, the first reference point and the second reference point, and establish a reference plane passing through the above three, the target center point is the center position of the ball cutter when it passes through the processing point to be compensated, The first reference point and the second reference point are the center positions of the ball cutter closest to the target center point on the adjacent processing path, and the adjacent processing path remains adjacent to the processing path where the target center point is located ;

[0078] Compensation fixed-point module 120, used to determine the normal vector of the reference plane, the intersection point of the normal vector and the cutting surface of the ball cutter, and calculate th...

Embodiment 3

[0090] see Figure 8 , the present embodiment provides a terminal 200, the terminal 200 includes a memory 210 and a processor 220, the memory 210 is used to store a computer program, and the processor 220 executes the computer program to enable the terminal 200 to implement the above-mentioned application in stone grinding curved surface processing ball cutter compensation method.

[0091] Wherein, the terminal 200 includes terminal devices (such as computers, servers, etc.) that do not have mobile communication capabilities, and also includes mobile terminals (such as smart phones, tablet computers, vehicle-mounted computers, smart wearable devices, etc.).

[0092] The memory 210 may include an area for storing programs and an area for storing data. Wherein, the storage program area can store the operating system, at least one application program required by the function (such as sound playback function, image playback function, etc.); the storage data area can store data cr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap