Building external wall face screeding and spray-coating device

A technology for building exterior walls and spraying devices, which is applied in the field of spraying devices and smoothing of building exterior walls. It can solve the problems of manual adjustment, limited precision, and difficulty in adjustment operations, and achieve the effects of simple use, high precision and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, the best mode for carrying out the present invention will be described based on the accompanying drawings.

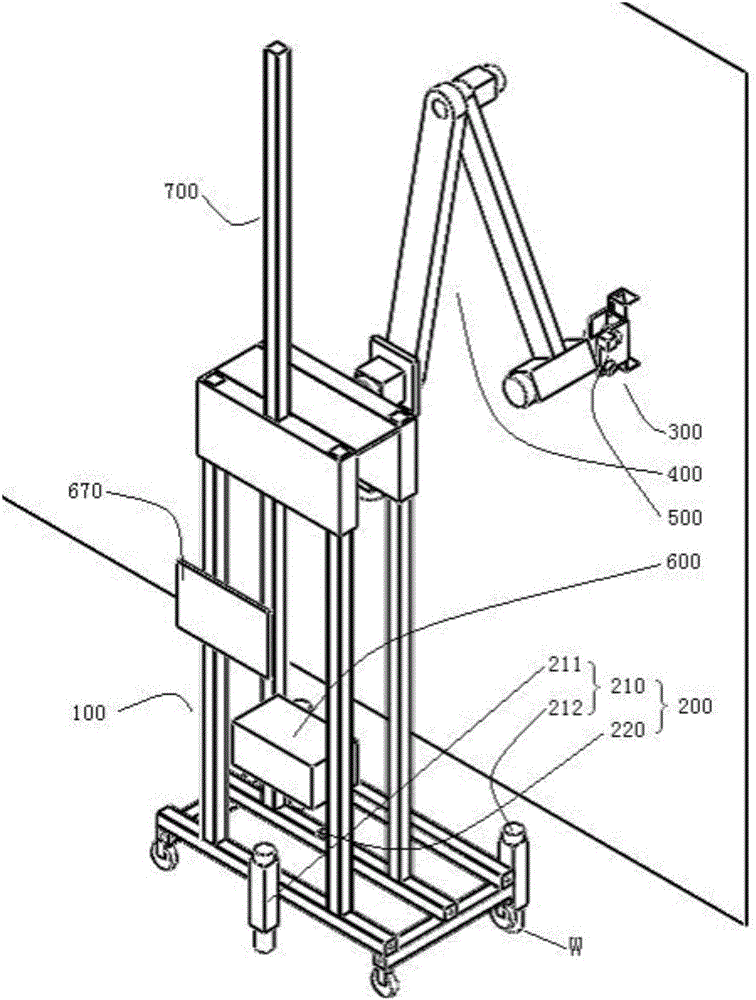

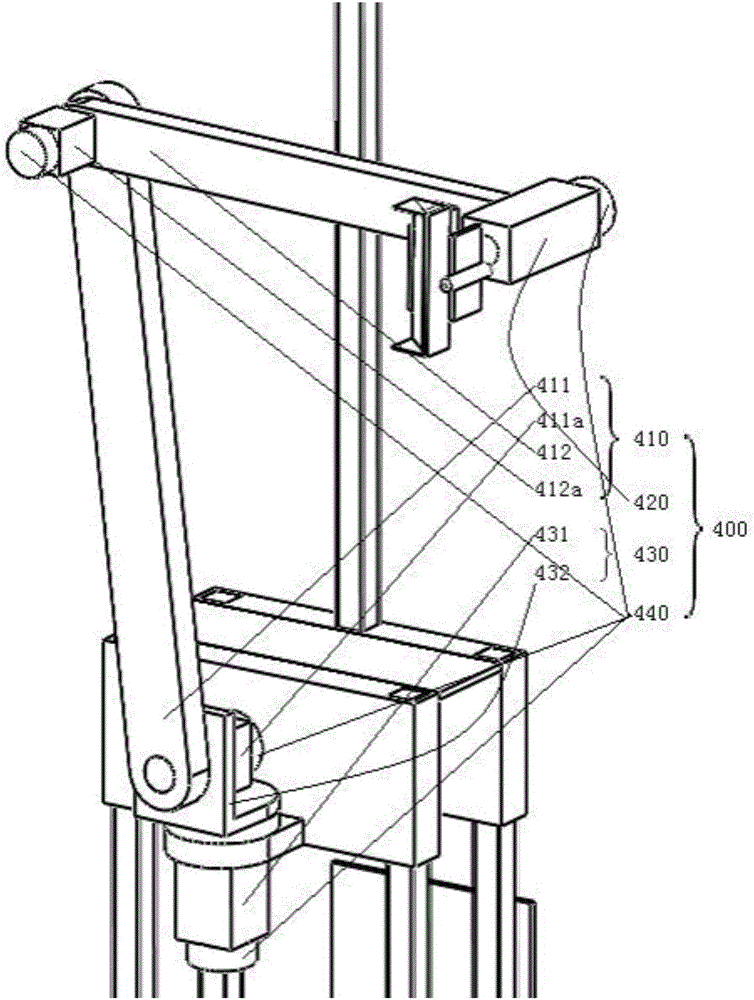

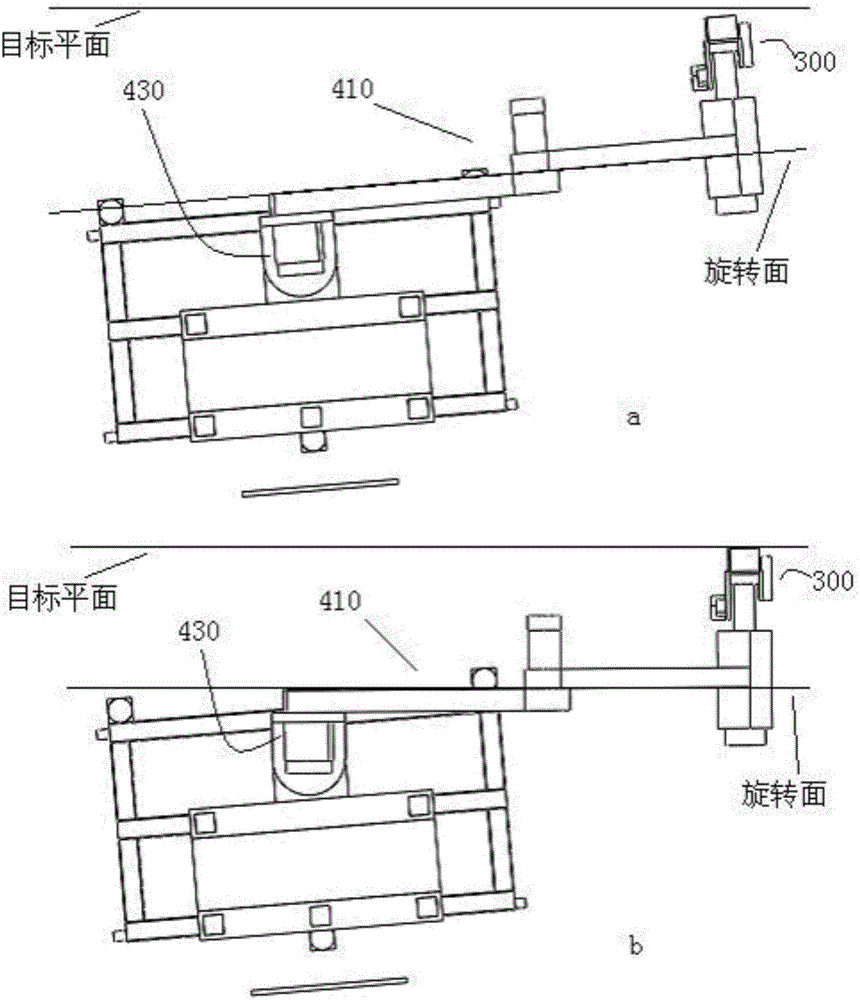

[0034] refer to figure 1 According to an exemplary embodiment of the present invention, the building exterior wall smoothing and spraying device includes a main body mechanism 100 , a posture adjustment unit 200 , a working head 300 , a movement mechanism 400 , a three-dimensional scanning device 500 , and a control unit 600 .

[0035] Continue to refer to figure 1 , a posture adjustment unit 200 is installed at the bottom of the above-mentioned main body mechanism 100 for adjusting the main body mechanism 100 to a vertical state during work.

[0036] Specifically, it includes three controllable telescopic outriggers 210 installed below the main mechanism 100 , and an inclination sensor 220 with a determinable installation position relationship with the main mechanism 100 . One controllable telescopic outrigger 210 is installed at the leftmost and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap