Anti-loose screen mesh

A technology of preventing loosening and sieve plate, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of easy loosening of the core tube and reduce the filtering effect of the core tube, and achieve the effect of preventing loosening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

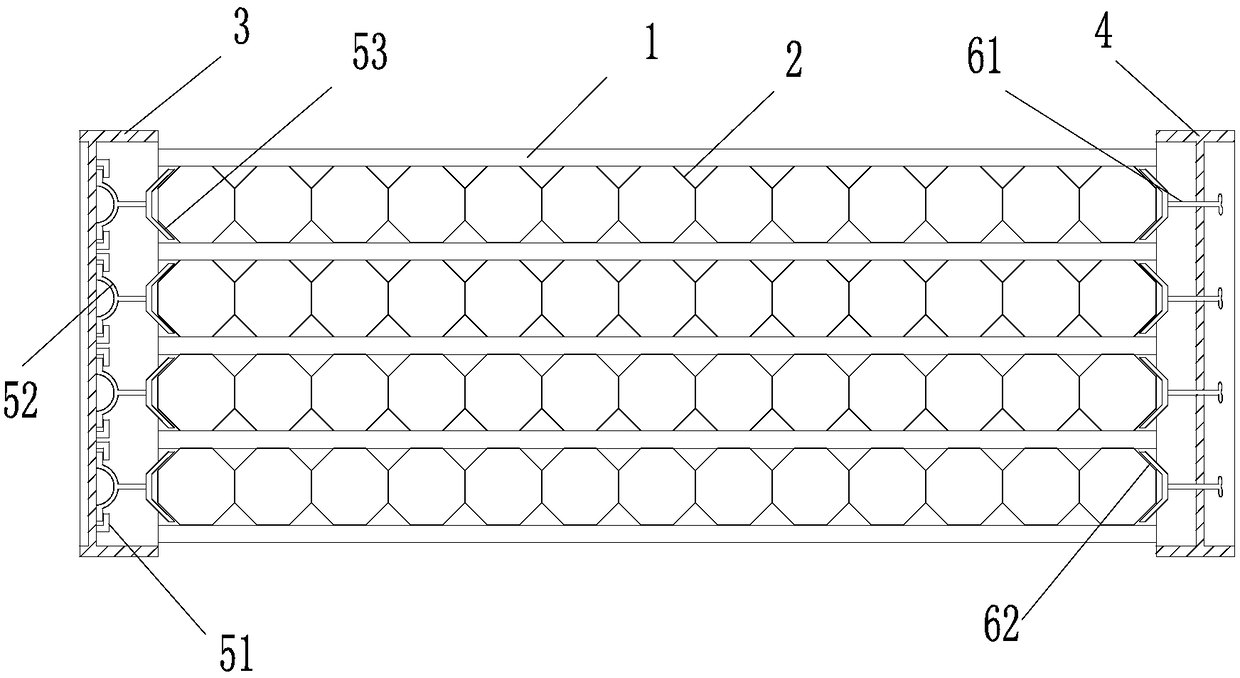

[0018] The present invention will be further described now in conjunction with accompanying drawing. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

[0019] Such as figure 1 As shown, an anti-loosening sieve mesh includes at least two base plates 1 and several core tubes 2 arranged between the two base plates 1, and the two sides of the base plate 1 are respectively provided with a left stopper 3 and a right stopper 4 ; The thickness of the core barrel 2 is >0.08mm. The hole depth of the through hole of the core barrel 2 is more than or equal to 5mm.

[0020] An elastic supporting device is arranged on the area opposite to the side wall of the core tube 2 in the left side stopper 3, and the elastic supporting device includes a pair of L-shaped buckles 51, elastic pressing pieces 52 and left pressing plate 53, and the two L-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com