Contact system of small-sized relay

A contact system and relay technology, applied in relays, electromagnetic relays, electromagnetic relay detailed information, etc., can solve the problems of product contacts affecting, affecting product performance, affecting product electrical parameters, etc., to achieve convenient and reliable wiring, and improve welding. Quality, the effect of improving the assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

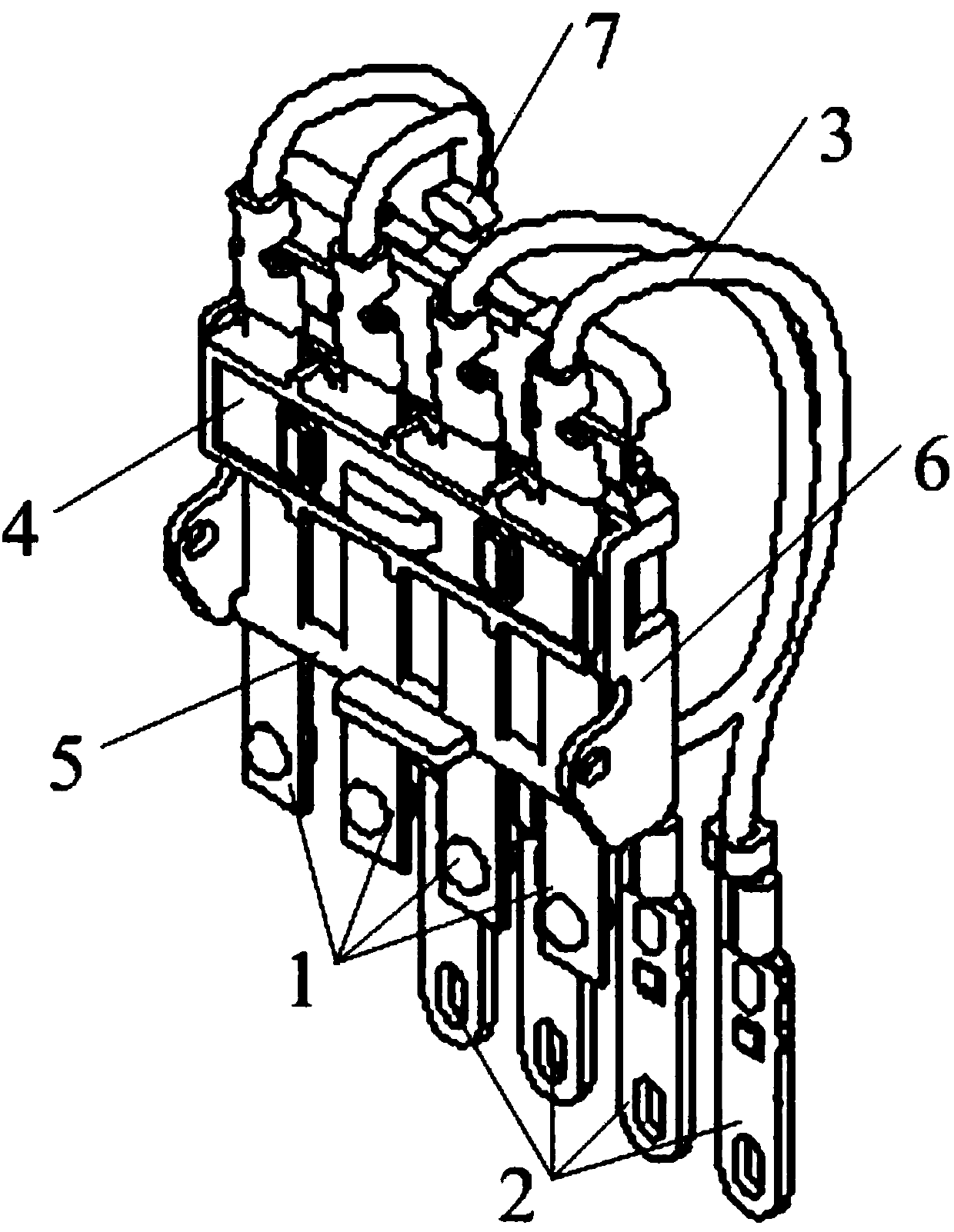

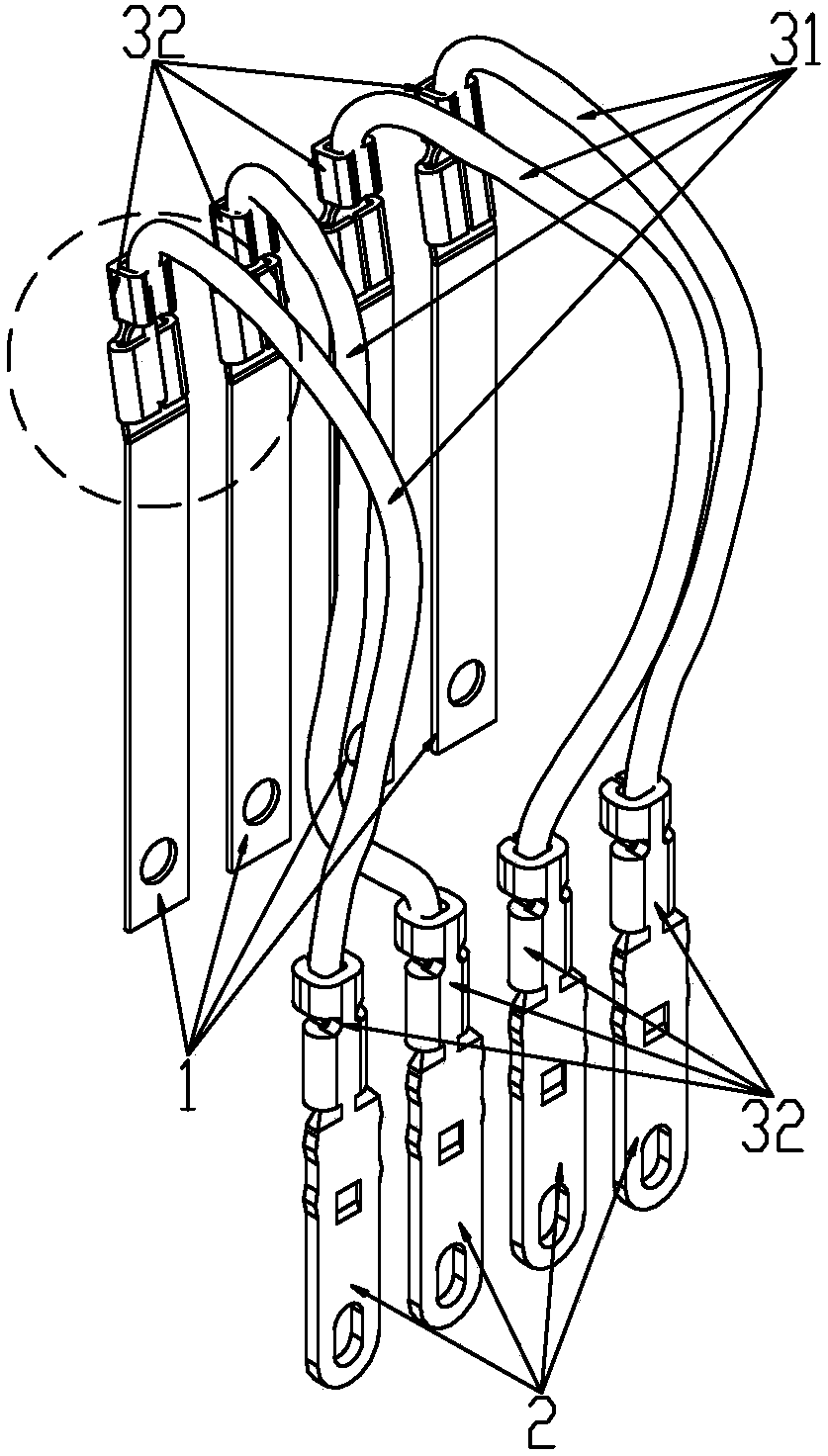

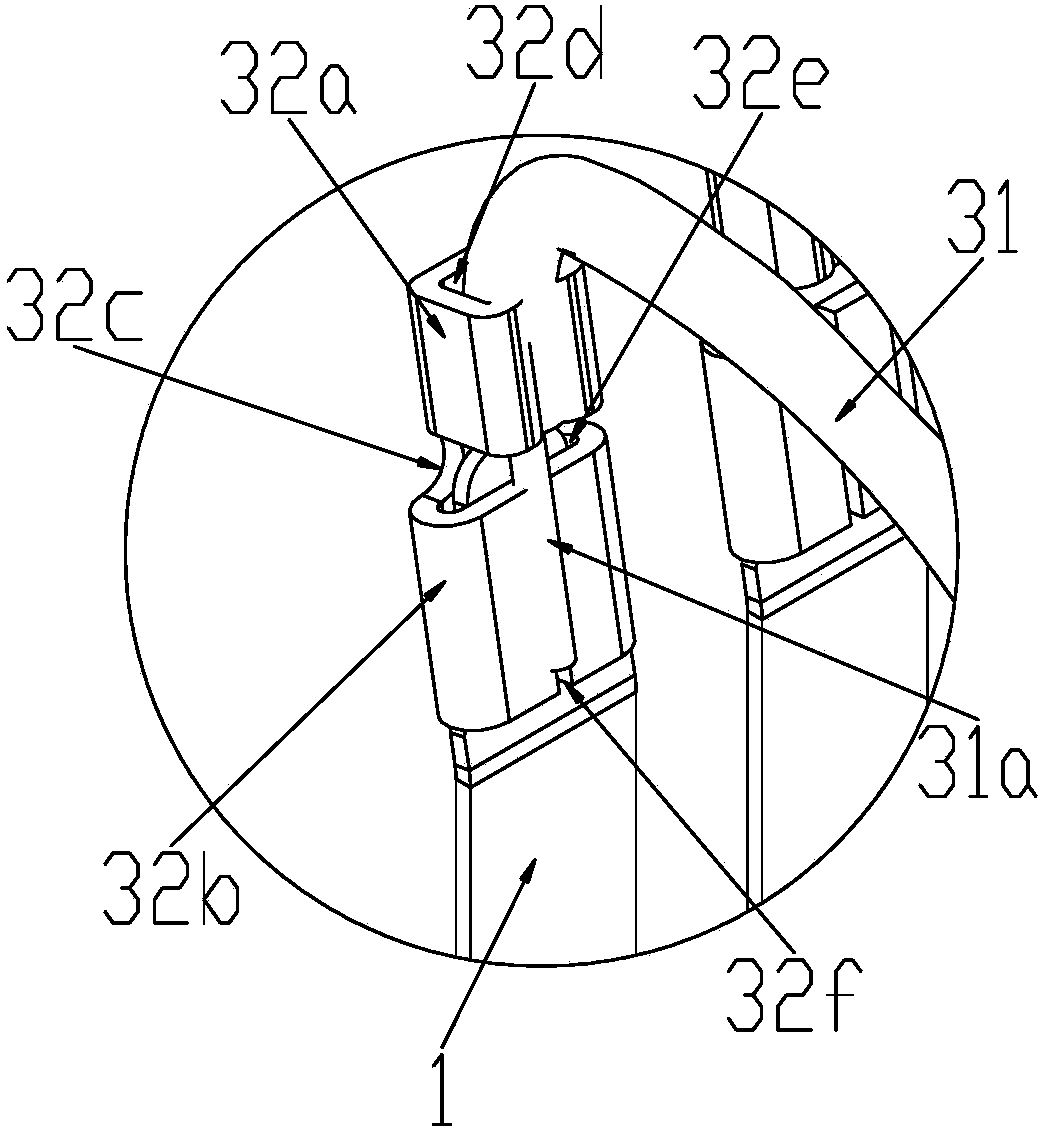

[0022] The following is attached Figures 1 to 6 The given examples further illustrate the specific implementation of the contact system of the small relay of the present invention. The contact system of the miniature relay of the present invention is not limited to the description of the following embodiments.

[0023] Such as figure 1 and figure 2 As shown, the contact system of the small relay of the present invention includes a moving reed 1 and a static reed 2, and one end of the moving reed 11 is arranged opposite to the static contact for controlling the on-off of the output circuit of the relay, and the moving reed The other end of 11 is electrically connected to the static reed 1 through the wiring assembly 3. The wiring assembly 3 includes a wire 31 and two elastic clips 32 respectively arranged at both ends of the wire 31. The two elastic clips 32 are respectively used to connect the wires. 31 and the moving reed 1 and the wire 31 and the static spring 2, one of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com