A welding treatment method suitable for steel pipe and steel pipe oblique combined forming

A processing method and a technology for steel pipes, which are applied in the field of steel pipe welding, can solve problems such as inconvenient qualitative inspection of the internal quality of welds, large gaps between steel pipes and steel pipes, and difficulty in ensuring welding quality, etc., so as to facilitate flaw detection and eliminate welding residues Effects of reducing stress and reducing the difficulty of welding construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

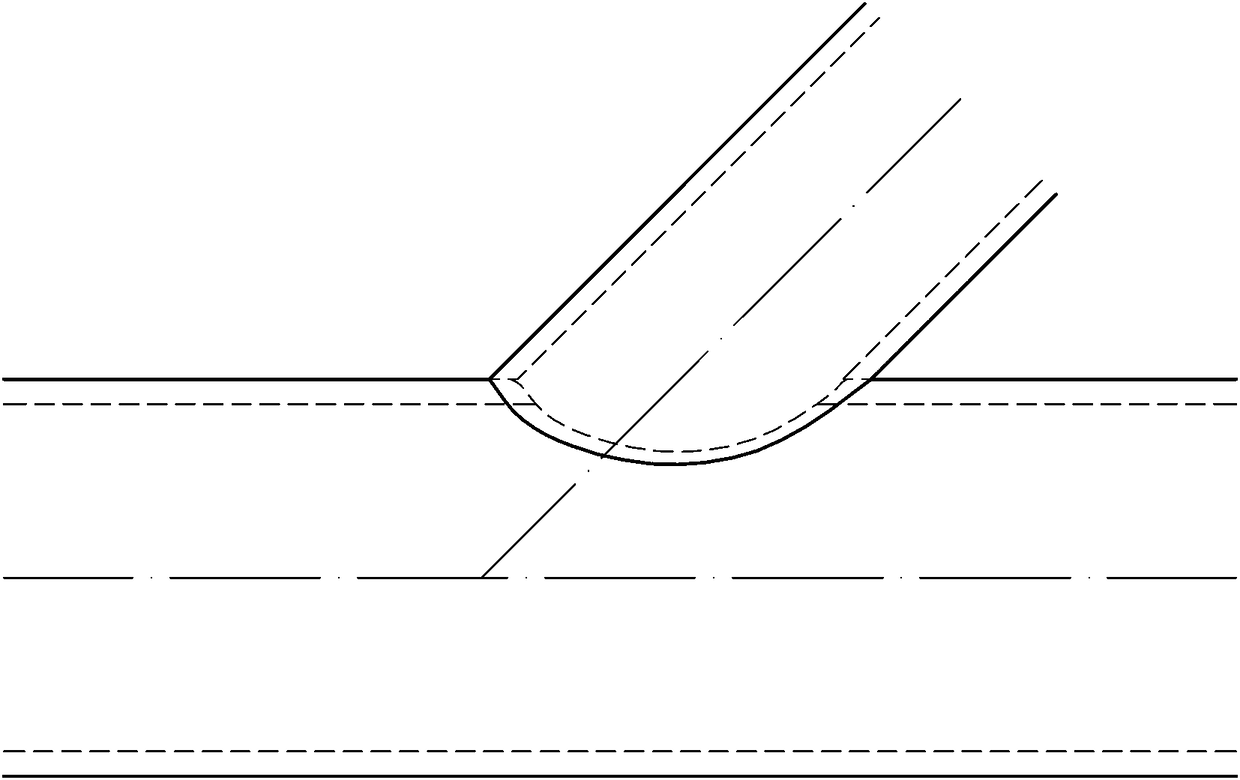

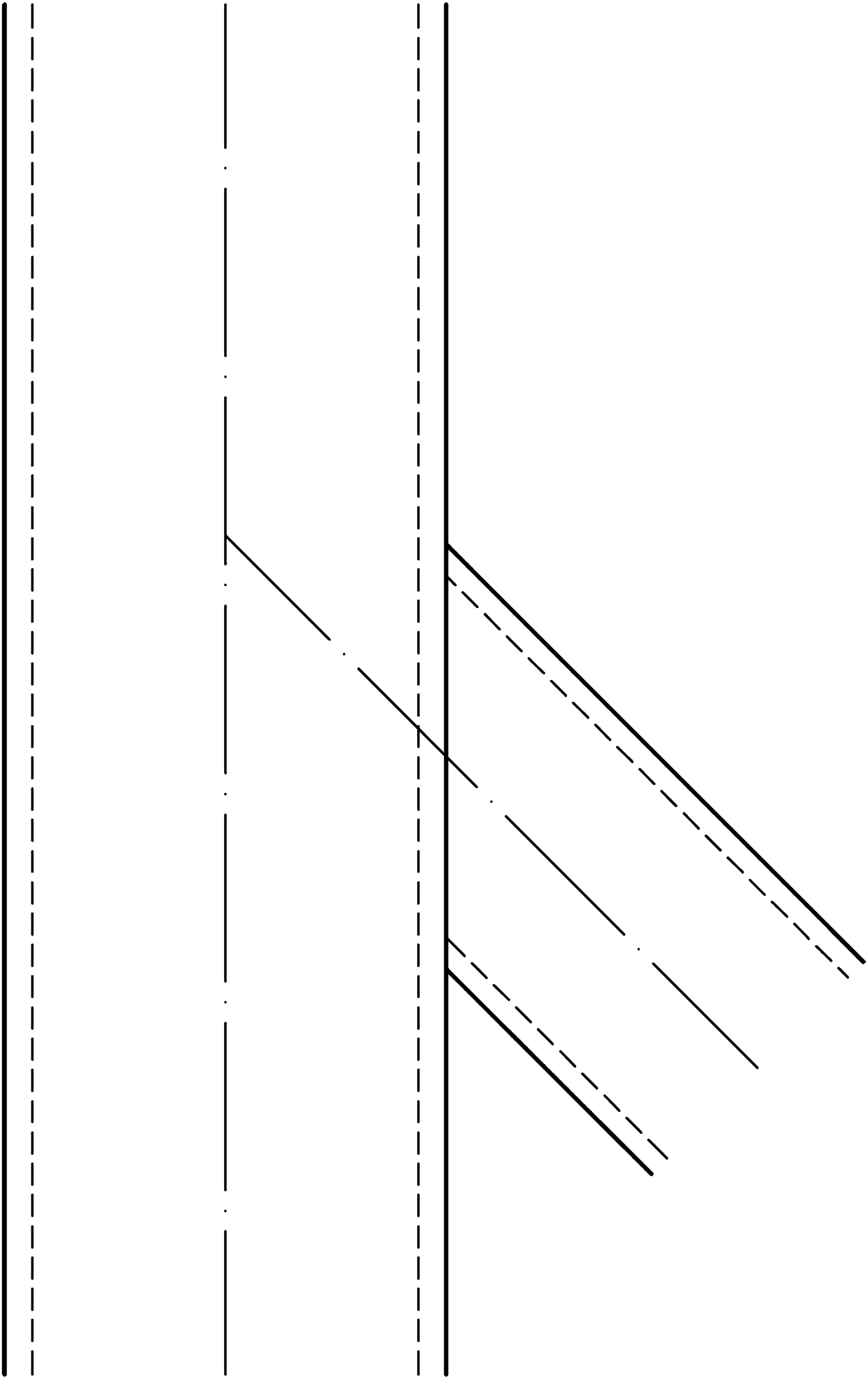

[0055] Such as Figure 5 Shown: When the welded rod is in a horizontal position, the weld is basically a horizontal welding position, and the manual welding technique in this position is easy to master. First, prepare the grooves in the manufacturing plant according to the design, and temporarily use the angle grinder to grind the grooves on the rods that need to be partially trimmed; then, tighten the assembly and perform multi-point spot welding on the welds for welding. ready. Secondly, welding is performed: the first pass realizes the bottom welding, and the symmetric welding completes the entire circle of welding; the subsequent welding is completed by the segmented welding method, multi-layer and multi-pass welding according to the divided weld area.

Embodiment 2

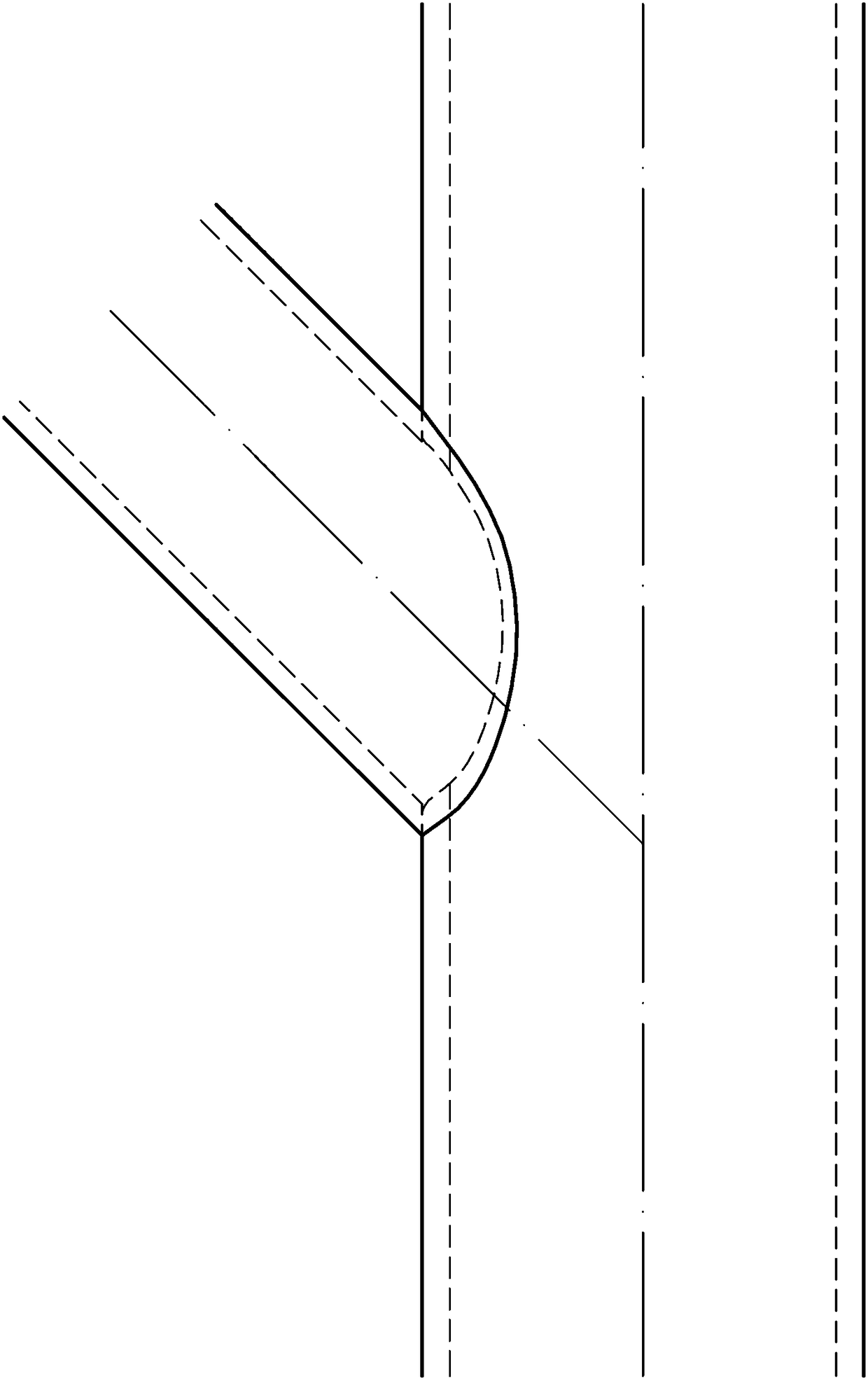

[0057] Such as Image 6 Shown: when the welded rod is in the vertical position and the top area is at the bottom, the top area θ 1 The range is the horizontal welding position, the side area θ 2 Uphill welding position, the root area θ 3 For flat fillet welding position, the top area of the welding joint θ 1 The welding is the most difficult. The previous preparation work is the same as that in Example 1. The welding sequence used in the welding process is: 1). Bottom welding: symmetric welding to complete the entire circle of welding. 2) Adopt segmented welding method, multi-layer and multi-pass welding: firstly, symmetric welding is completed θ 2 Zone weld; then, weld θ 3 For the flat fillet weld in the area, the welding thickness reaches half; secondly, the welding is completed θ 1 Upside down welding of the area; finally, complete θ 3 Welding of flat fillet welds. 3), cover welding: the whole weld cover the surface. If the welding sequence is completed in this way, the qu...

Embodiment 3

[0059] Such as Figure 7 Shown: When the welded rod is in the vertical position and the top area is on the upper part, the root area θ 3 The range is the horizontal welding position, the side area θ 2 For upward slope welding, the top area θ 1 For flat fillet welding position. Since the root area θ 3 It belongs to the acute-angle horizontal welding position, and the transportation and the line of sight are not very good, and the welding seam operation is particularly difficult. The welding sequence used in the welding process is: 1). Bottom welding: first in the flat fillet welding position θ 1 In the root area θ 3 The bottom of the zone and the horizontal welding position are sealed and welded together. 2) Adopt segmented welding method, multi-layer and multi-pass welding: firstly, symmetric welding is completed θ 2 Zone weld; then, weld the top θ 1 The flat fillet weld in the area, the welding thickness reaches half; secondly, the root of the welding is completed θ 3 Upside do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com