Labyrinth type mounting structure of brake and aluminum wheel

A technology of installation structure and brake, applied in the components of brake, brake type, mechanical equipment, etc., can solve problems such as hidden safety hazards, affect the braking effect of brakes, etc., and achieve the effect of safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with drawings and embodiments.

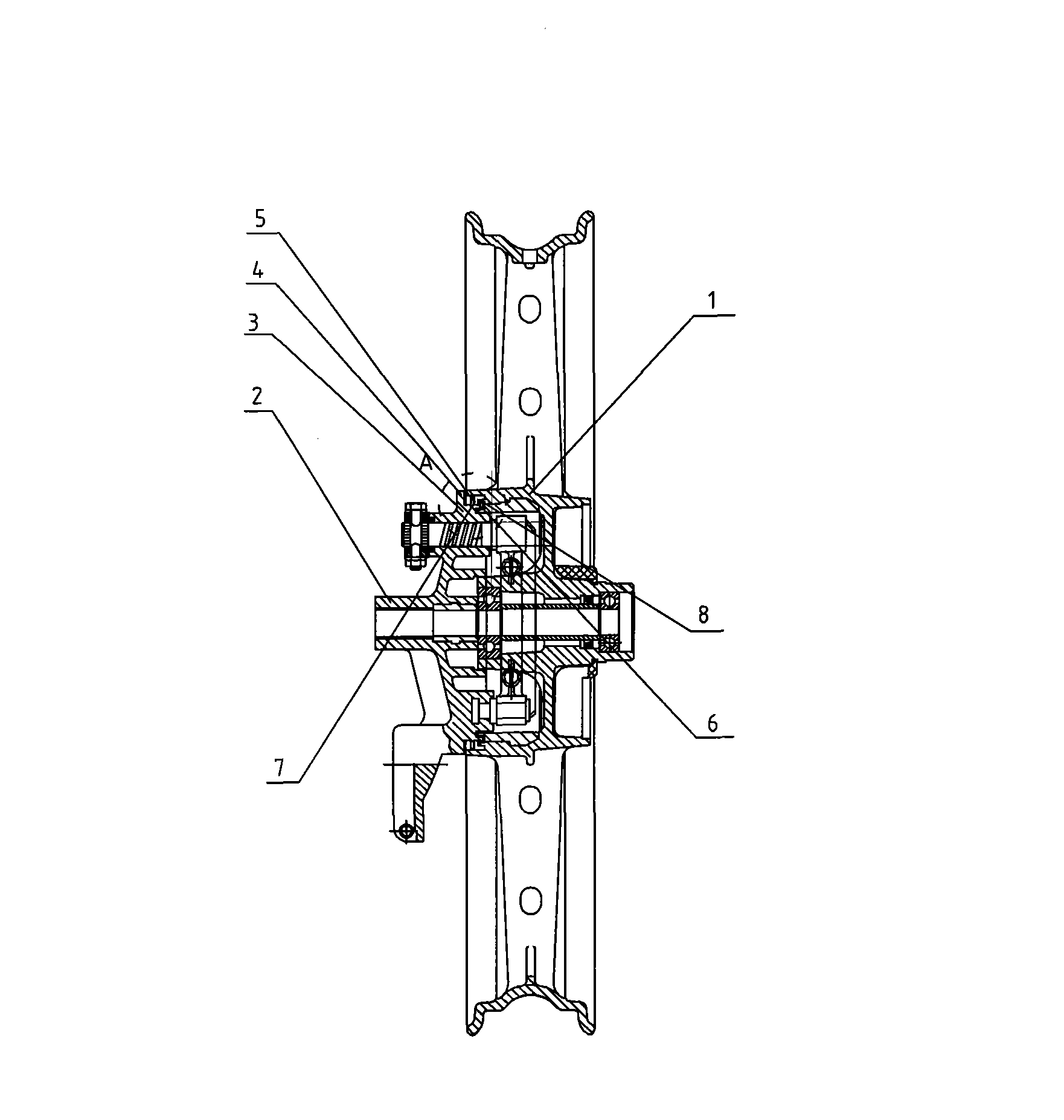

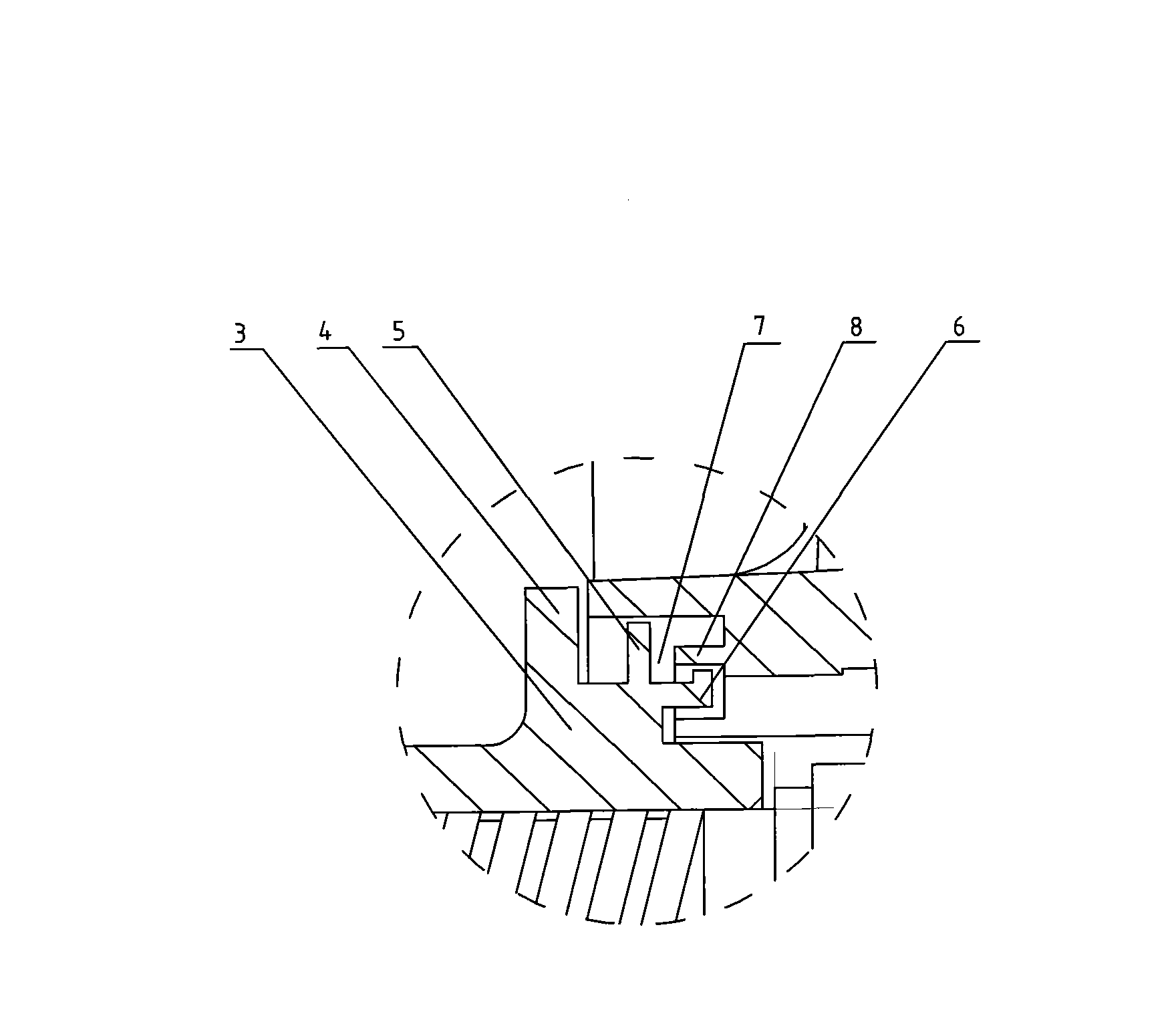

[0012] A labyrinth installation structure on a brake and an aluminum wheel, which includes an aluminum wheel 1 and a brake 2, and on the brake drum cover 3 of the brake 2, there are three ring platforms that are stepped and gradually lower in height, from the inside to the outside The first ring platform 4, the second ring platform 5 and the third ring platform 6 in sequence, a groove 7 is formed between two adjacent ring platforms, the first ring platform 4 is located on the outer end surface of the aluminum wheel 1, and the second ring platform 5 Against the inner wall of the aluminum wheel 1, the third ring platform 6 is against the boss 8 on the aluminum wheel 1.

[0013] When the motorcycle is running, the dust penetrates into the brake 2 through the gap between the aluminum wheel 1 and the brake 2. When the dust penetrates to the groove 7, it falls into the groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com