Explosion-proof elevator

An elevator and car technology, applied in the field of explosion-proof elevators, can solve problems such as large limitations, potential safety hazards, and temperature rise, and achieve the effects of ensuring safety, improving comfort, and facilitating installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

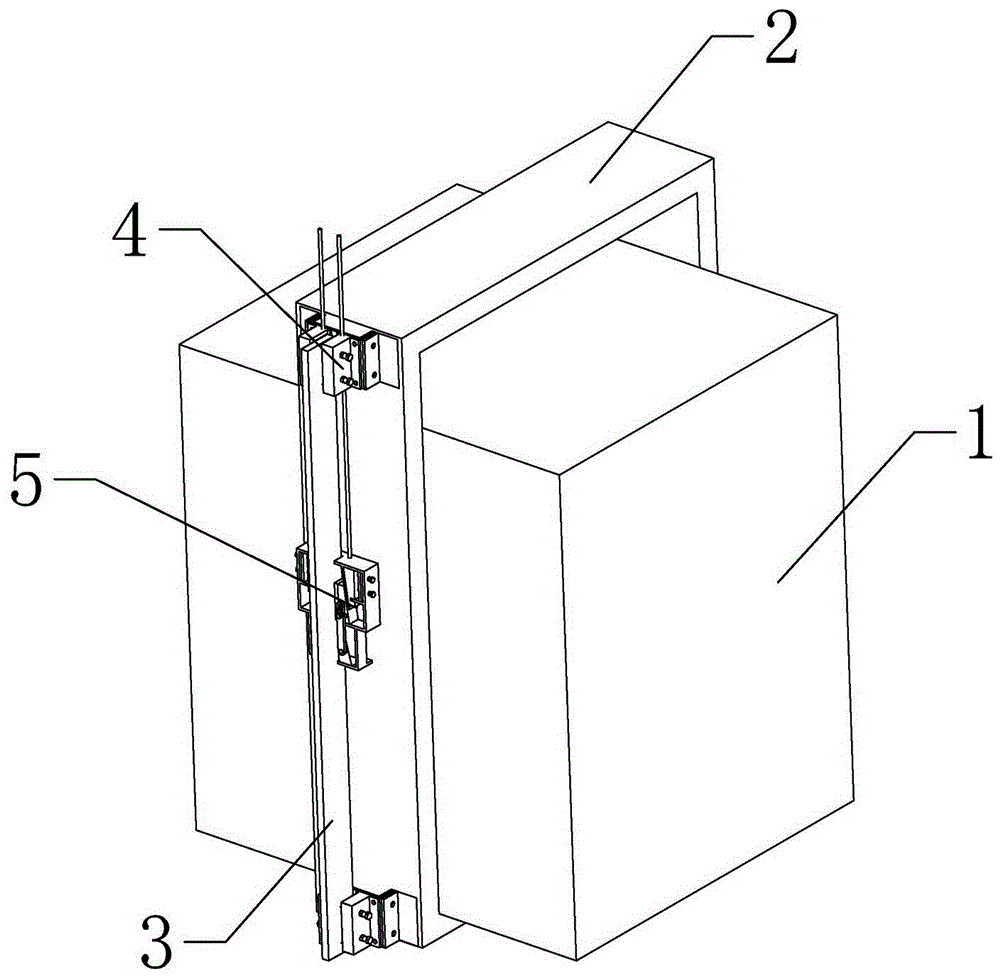

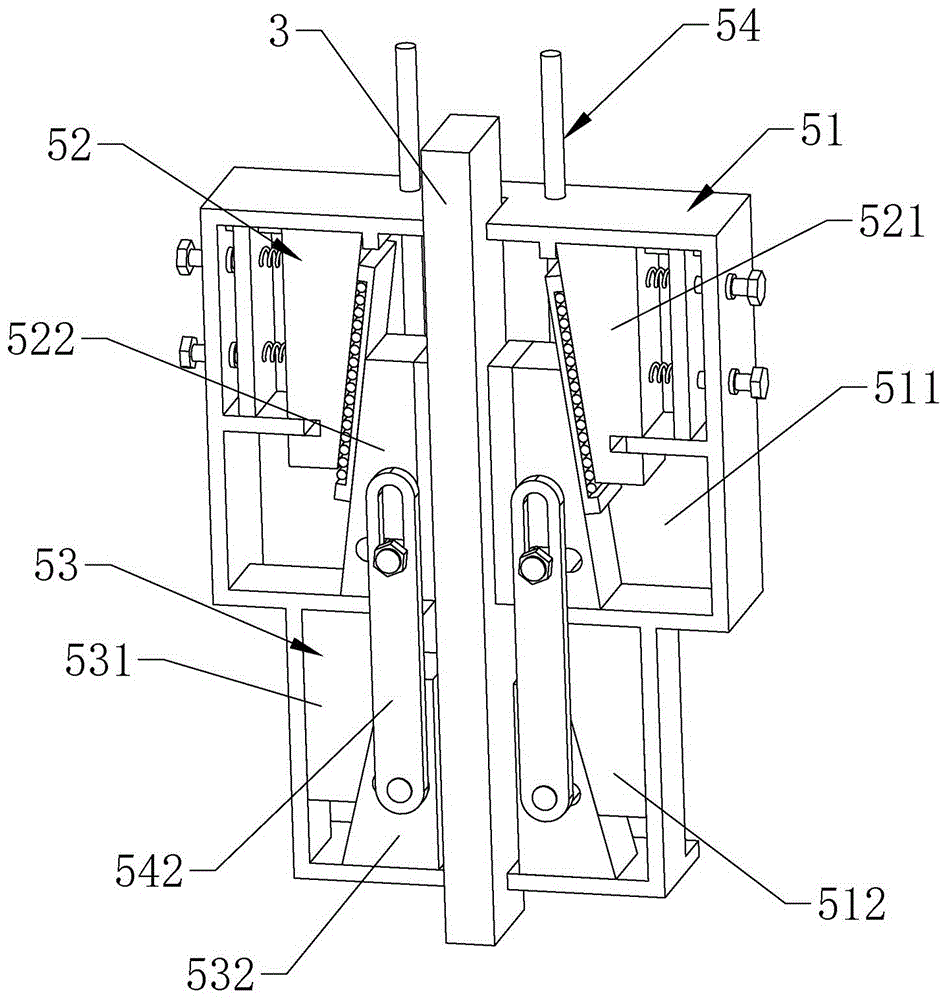

[0036] according to Figure 1 to Figure 6 Shown, a kind of explosion-proof elevator comprises, the car 1 in the hoistway, the car beam 2 that fixes the car, the guide rail 3 that guides the car and the guiding device; One side, including guide shoe 4 and safety gear 5;

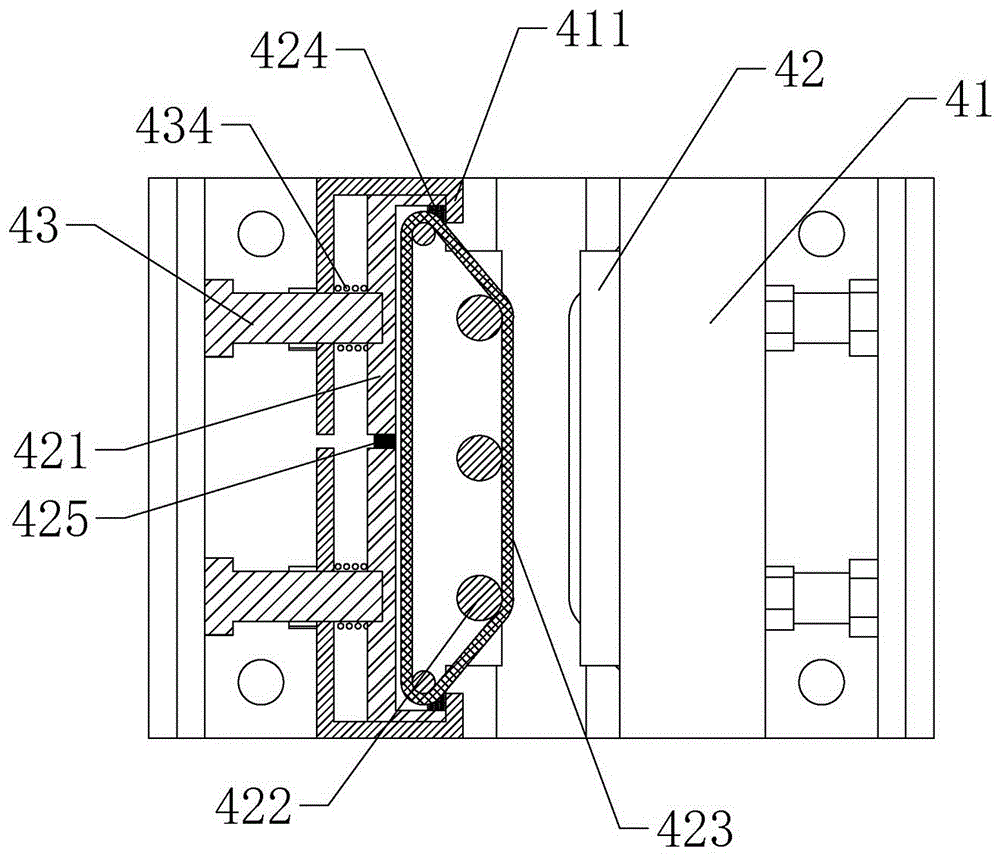

[0037] Guide shoe 4 comprises, guide shoe seat 41, guide block 42 and adjusting bolt 43, and guide block 42 is arranged in the guide shoe seat 41, and adjusts the gap with guide rail 4 by adjusting bolt 43; The movable block 421 inside the shoe seat 41, the rotating shaft 422 and the guide belt 423 arranged in the movable block 421; an adjustment spring 434 is arranged between the inner wall of the guide shoe seat 41 and the movable block 421, and the adjustment spring 434 is sleeved on the adjustment bolt 43 ; The inner side of the guide shoe seat 41 is provided with a limiting block 411 that limits the movable block 421; a sealing block 424 is arranged between the movable block 421 and the guide belt 423, s...

Embodiment 2

[0044] The difference from the above-mentioned embodiment 1 is that, according to Figure 7 , Figure 8 As shown, the guide shoe 4 and the safety gear 5 are connected to the car beam 2 through the mounting frame 6. The mounting frame 6 includes a fixing plate 61 and an adjusting plate 62, and a first adjusting gasket is arranged between the fixing plate 61 and the adjusting plate 62. 63 , a second adjusting gasket 64 is provided between the adjusting plate 62 and the car beam 2 , and the car beam 2 is provided with a mounting hole 21 for fixing the mounting frame 6 .

[0045] The section of the fixing plate 61 is C-shaped, and its two ends are provided with flanges 611; the section of the adjusting plate 62 is L-shaped, including a first fixed edge 621 and a second fixed edge 622; the first adjusting gasket 63 is arranged on the first Between the fixed edge 621 and the folded edge 611 , the second adjusting gasket 64 is arranged between the second fixed edge 622 and the car b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com