Temperature sensing box, refrigerator and freezer

A temperature sensing probe and cabinet technology, applied in the field of refrigerators and freezers, can solve the problems of leaking bubbles in the box, scrapped boxes, and inability to fix the temperature probe effectively, so as to prolong the fresh-keeping period, keep the temperature accurate, and avoid excessive temperature. high or low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

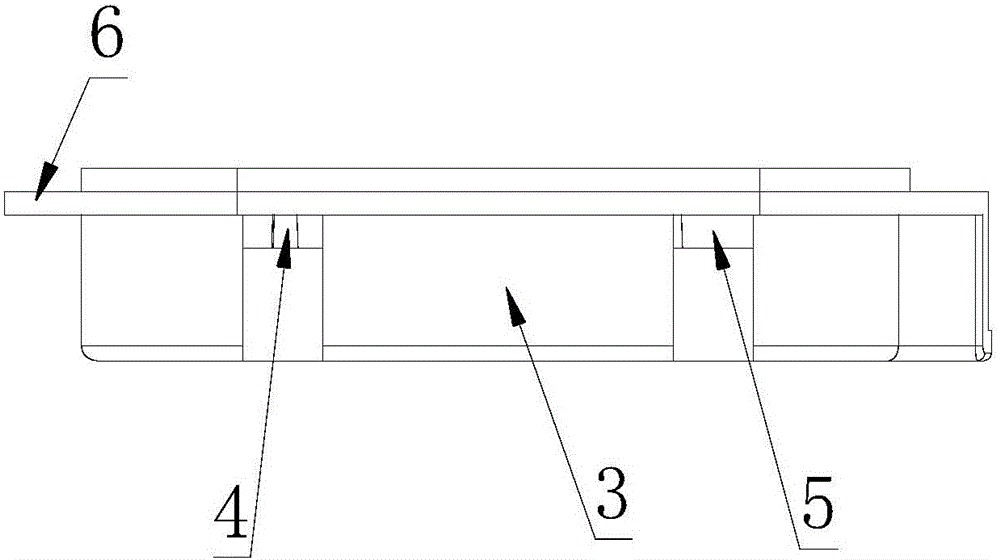

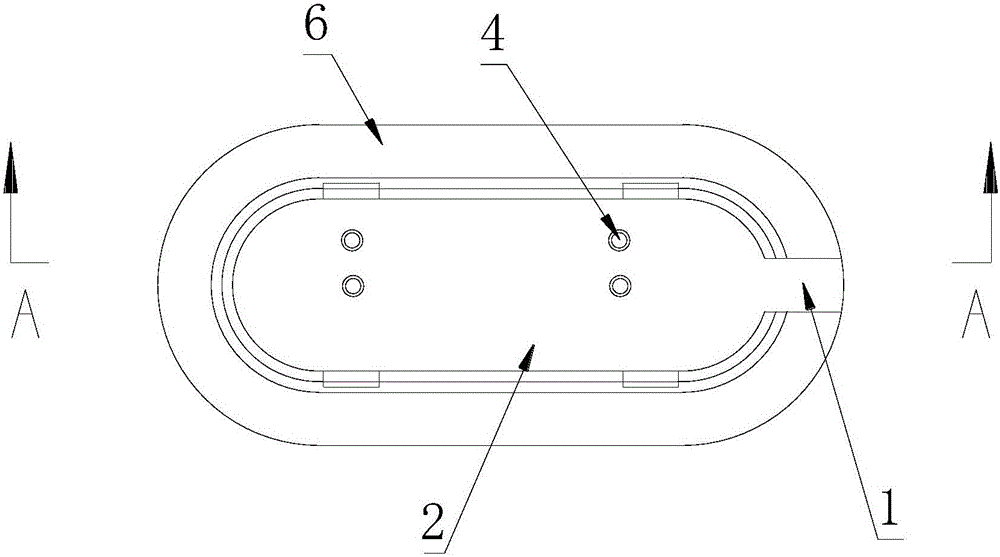

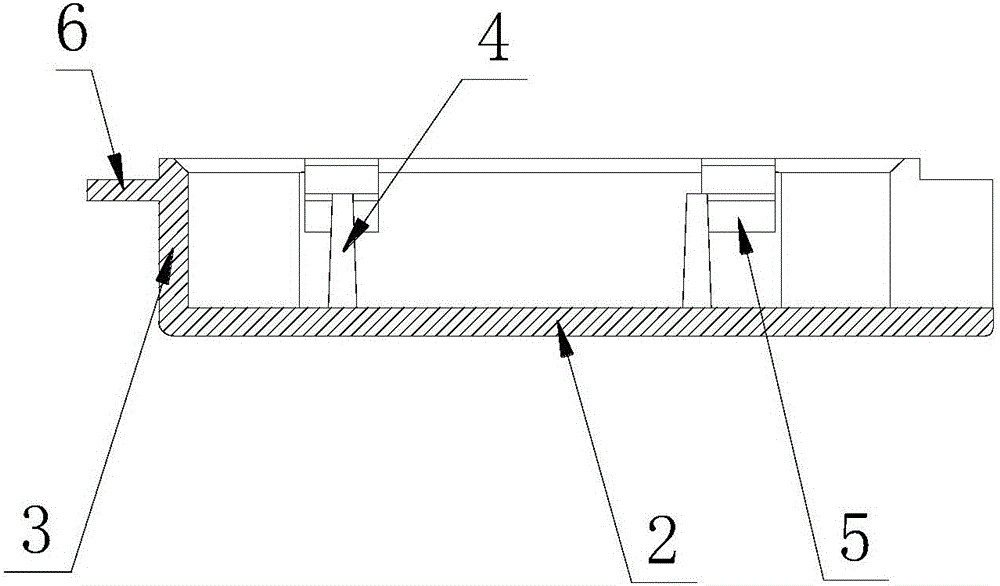

[0038] A temperature sensing box includes a pre-embedded box body and a cover body, and the cover body is detachably installed on the pre-embedded box body.

[0039] Such as Figure 1 to Figure 3 As shown, the pre-embedded box body includes a bottom plate 2 and an annular side plate 3, and one end of the annular side plate 3 is fixedly installed on the bottom plate 2, so that the bottom plate 2 and the annular side plate 3 form a box body for placing a temperature sensor . The bottom plate 2 is a flat oval structure; the flat oval is composed of a rectangle and two semicircles, the two semicircles are respectively on two opposite sides of the rectangle, and the diameter of the semicircle coincides with the sides of the rectangle, And the length of the diameter is equal to the length of the side. Since the temperature-sensing probe has a cylindrical structure, and the first accommodating space is also a strip-shaped structure, it coincides exactly. The volume of the pre-embe...

Embodiment 2

[0062] A refrigerator includes a box body, and a temperature-sensing box as described in Embodiment 1 is installed in the box body.

Embodiment 3

[0064] A refrigerator includes a cabinet body, and a temperature-sensing box as described in Embodiment 1 is installed in the cabinet body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com