Method for predicting washout service life of oil well sand control screen

A sand control screen and life prediction technology, which is applied to measuring devices, wear resistance testing, instruments, etc., can solve the problems that have not yet been proposed such as sand control screen erosion life, prediction methods, etc., to achieve strong practicability, ensure safety, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0031] A method for predicting the erosion life of an oil well sand control screen comprises the following steps:

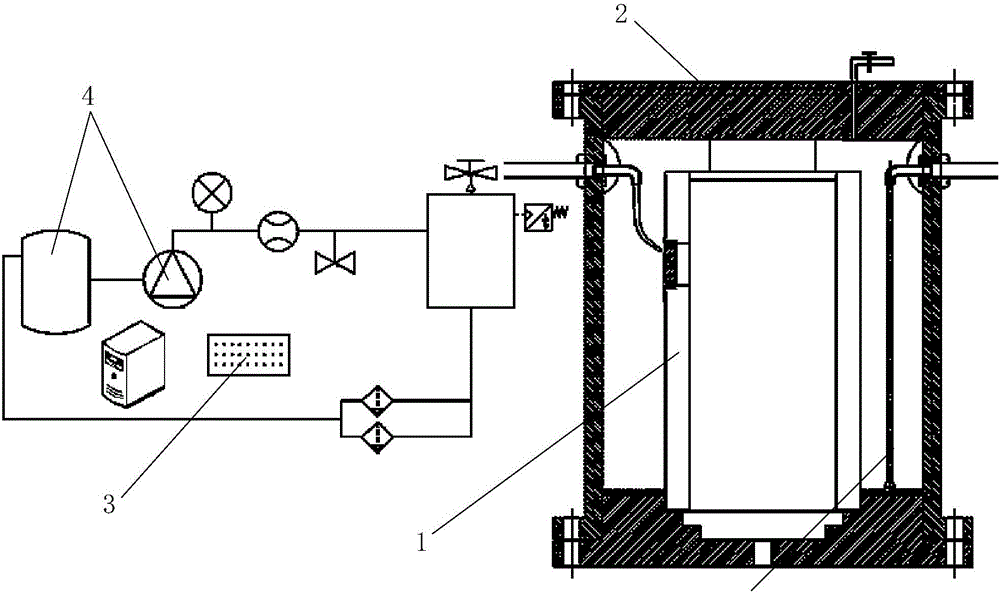

[0032] 1) For the sand control screen used in the target oil well, carry out the indoor erosion test of the sand control screen to truly simulate the state and actual production of the sand control screen in the oil well, and collect the experimental time, experimental flow rate, experimental fluid concentration, and screen loss quality , experimental pressure and other experimental data.

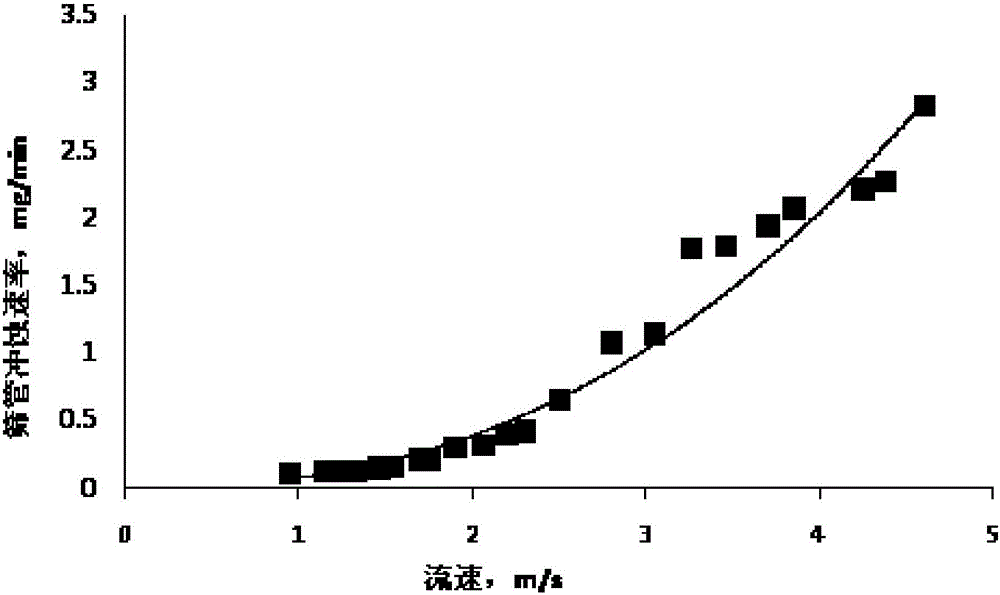

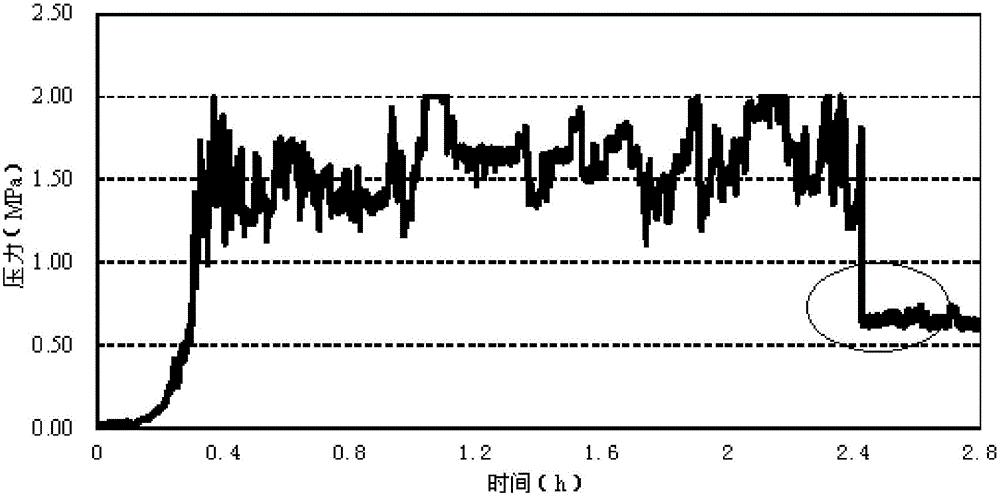

[0033] 2) Weigh the loss mass difference of the sand control screen before and after the experiment, and divide the loss mass difference by the test time to get the screen erosion rate. According to the experimental data obtained in step 1), draw the variation curve of the experimental pressure with the experimental time. When the sand control scree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com