A high-altitude cable inspection equipment

A high-altitude cable and equipment technology, applied in the field of high-altitude cable inspection equipment, can solve the problems of affecting detection efficiency and low detection efficiency, and achieve the effect of convenient real-time monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

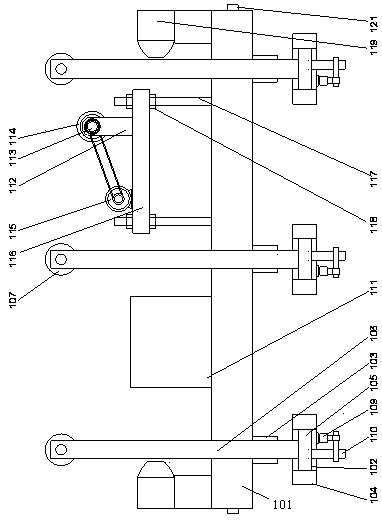

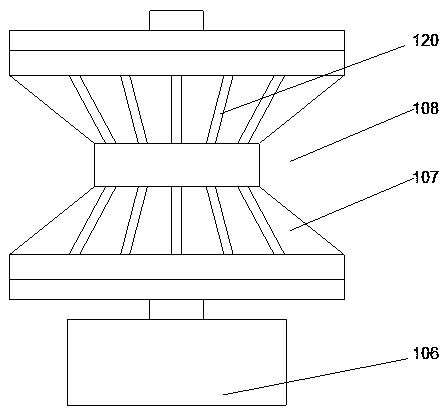

[0021] Such as figure 1 , 2 As shown in , 3, a high-altitude cable inspection equipment includes a base 101 and three moving support plates 102 respectively arranged under the two sides of the base 101, and the width of the moving support plates 102 is larger than that of the base The width of 101, the first hydraulic cylinder 103 is respectively arranged above the two ends of the moving support plate 102, the bottom of the first hydraulic cylinder 103 is fixedly connected to the upper end surface of the moving support plate 102, and the The telescopic rod of the first hydraulic cylinder 103 is fixedly connected to the lower end surface of the base 101, and two flanges 104 are arranged on the side wall of the moving support plate 102, and a rotating shaft is arranged between the flanges 104. 105, the two ends of the rotating shaft 105 are rotatably connected to the flange 104 through bearings, the vertical rod 106 is set on the rotating shaft 105, and the end of the vertical ...

Embodiment 2

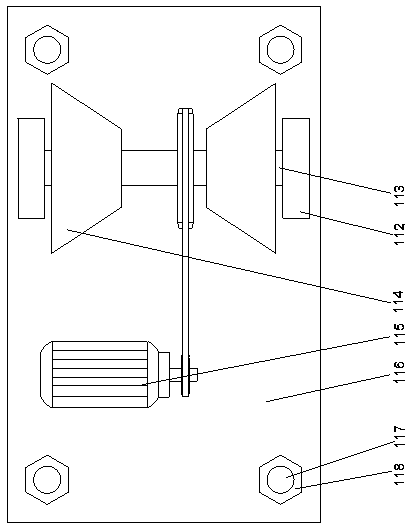

[0026] In this embodiment, in order to facilitate the adjustment of the height of the gear so that it can fit on the cable better, preferably, a lifting plate 116 is arranged on the upper end surface of the base 101, and the lifting plate 116 is provided with a stud 117, the lower end of the stud 117 is fixedly connected to the base 101, the upper end of the stud 117 runs through the lifting plate 116, and the two sides of the lifting plate 116 Adjusting nuts 118 are arranged on the studs 117 respectively, and the motor 115 and the bracket 112 are respectively fixedly connected to the upper end surface of the lifting plate 116 . When needed, turn the adjusting nut to make the stud move longitudinally. During the longitudinal movement of the stud, the lifting plate is driven to move longitudinally, so that the height of the lifting plate can be adjusted, and then the height of the gear can be adjusted so that the gear can fit better. It fits under the cable and is suitable for ...

Embodiment 3

[0029]In order to increase the friction between the gear and the cable and make the overall structure more reliable, in this embodiment, preferably, the gears 114 are two symmetrically arranged on the fixed shaft 113, two The gears 114 are arranged symmetrically below the two sides of the cable.

[0030] In order to make the gear fit better on the cable, in this embodiment, further preferably, the gear 114 is a straight bevel gear. Fit the straight bevel gear under the sides of the cable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com